oem custom quality stamping flat crimp type terminal lugs

Item | Description |

Material | stainless steel(304,301,316,etc), copper(Phosphor copper,brass,beryllium copper,red copper,Copper-Nickel-Zinc Alloy),nickel,etc |

Tolerance | 0.01mm |

Thickness | 0.05-2mm,specialize in 0.2-0.6mm |

Surface Finish | electroplating(Chromium,nickel,zinc,tin,silver,gold,etc),anodicoxidation,Spray paint,passivation,etc |

Other Finish | tapping,welding,heat treatment,laser engraving,etc |

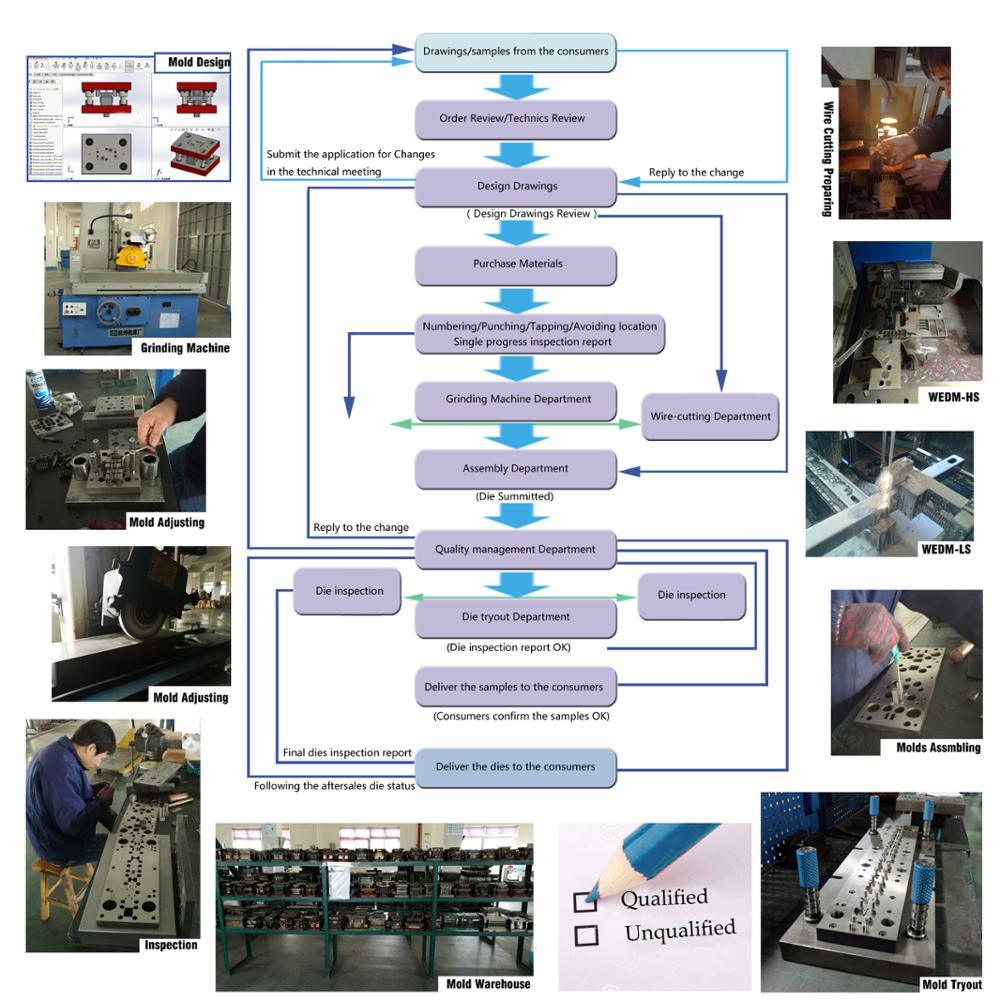

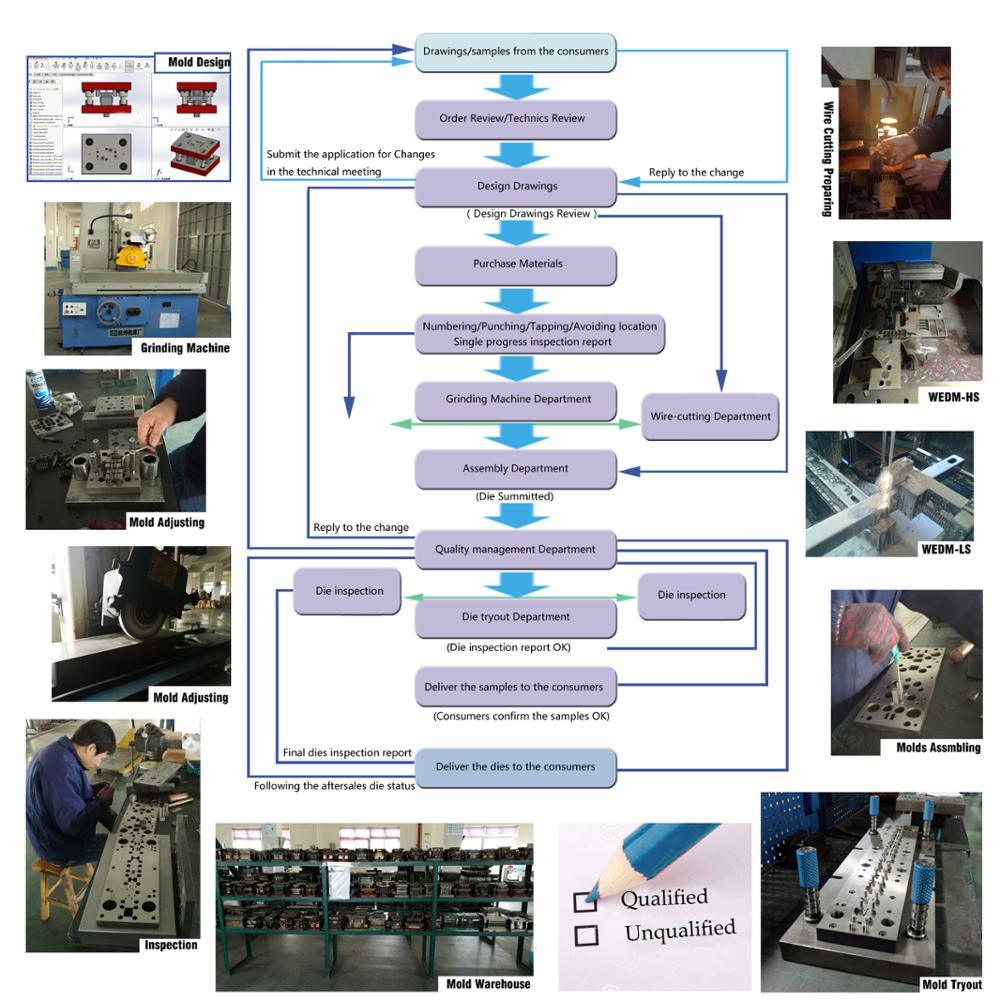

The products shown here is only to present the scope of our major business.We've been focused on professionally customized metal stamping parts and plastic injection molding parts since 1983.Our equipments include high speed automatic stamping machines(6.3tons-160tons), injection plastic machines(90tons-160tons),and etching machine.Mold processing machines include WEDM-LS,WEDM-ML,WEDM-HS,CNC,grinding machine,miller,wire-EDM,electro-discharge machine.

Item | Index | Description |

Metal Stamping Die | Material of Die | 45#,Cr12,Cr12MoVl,SKH-9,SKD11,CD650,ASP23,DC53,etc |

Material of punch | SKH-9 SKD11 CD650 ASP23 |

Material of blade | CD650 SKD11 SKH-9 |

Material of form block | DC53,SKH-9,ASP23 |

Processing technic | WEDM-LS,WEDM-MS,WEDM-HS,PG |

Stamping Equipment | 6.3-160Ton |

Mold heat treatment | Up to 60-62 degrees and above |

Die Precision | 0.005mm,0.002mm, |

Brand of guide pin | MISUMI |

Platic Injection Mold | Material of cavity | NAK80,S136H,2316,2316A,etc |

Processing technic | CNC,WEDM-LS,EDM |

Brand of die blank | LUNG KEE |

Shanghai Xianghang Precision Mold Co.,Ltd was founded in 1983, specializing in precision metal stamping& plastic injection molding,mold design and manufacturing.

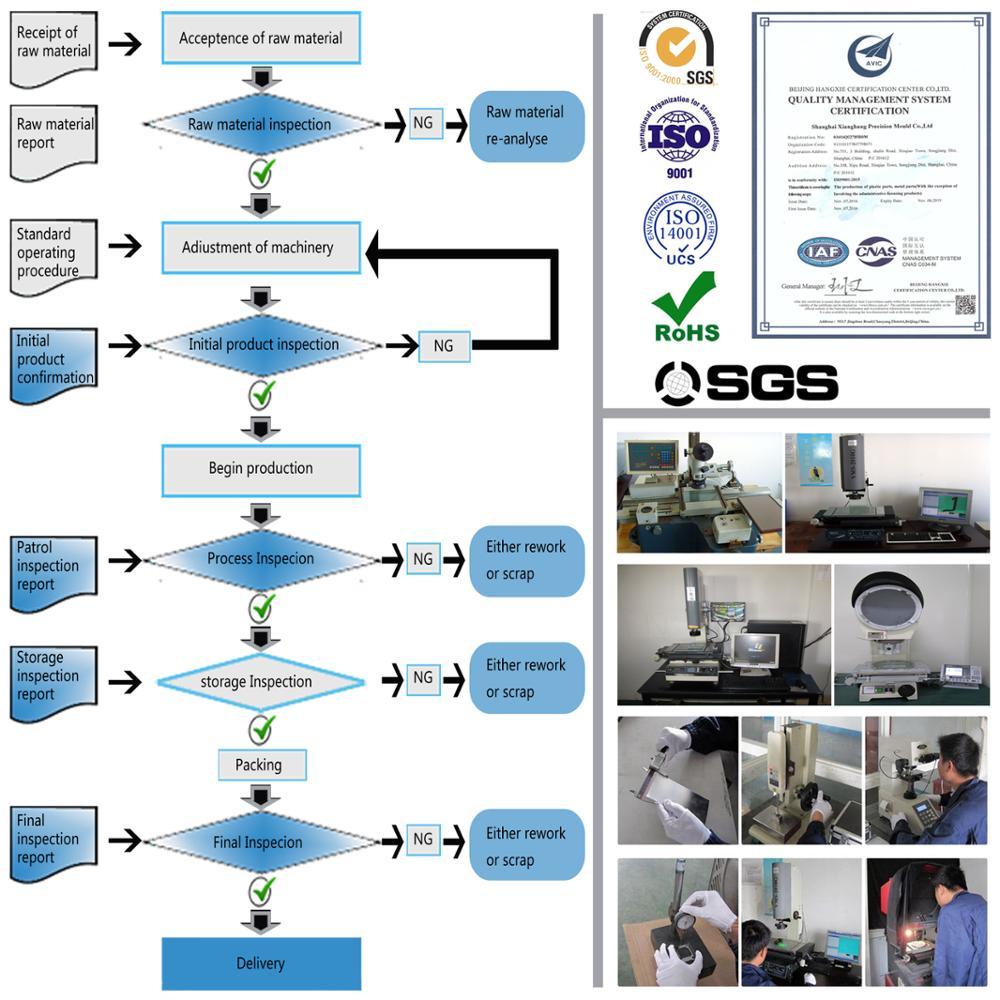

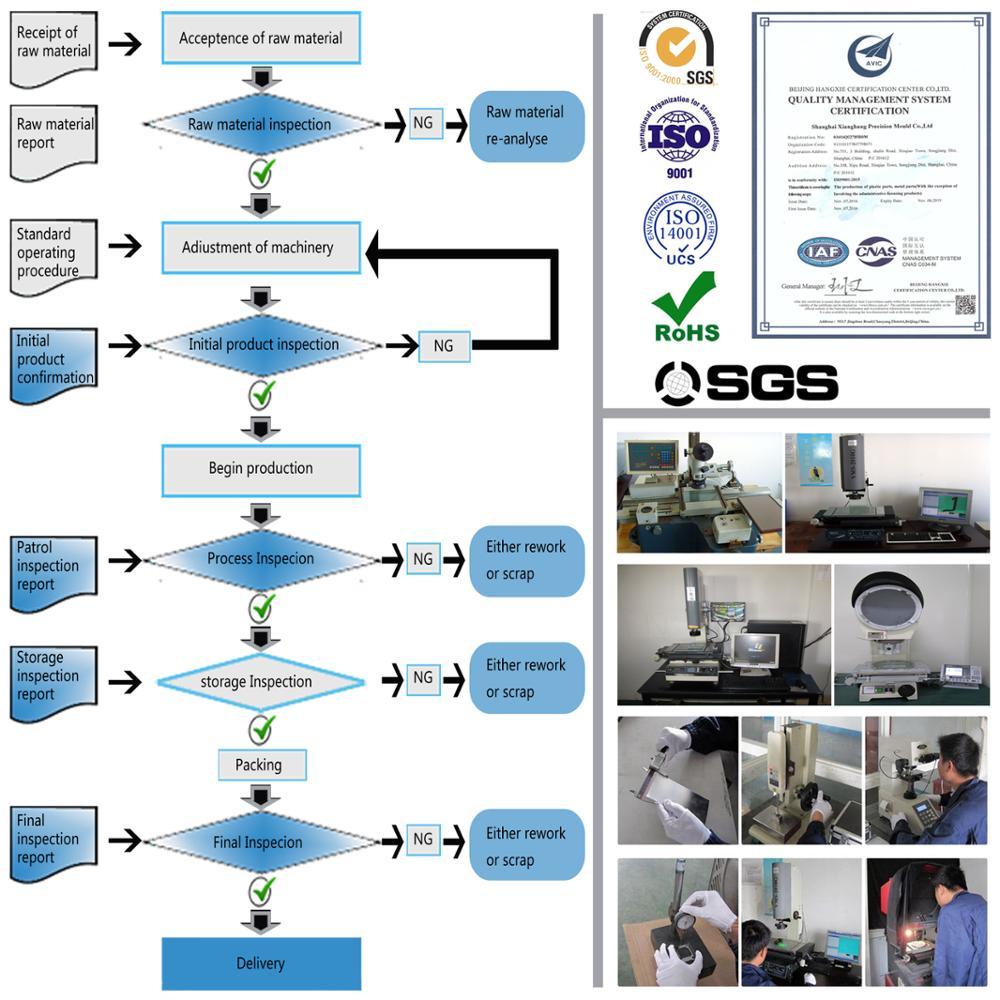

Our molds are always with high precision,long service life and efficient production. 95% of mold are progressive,and 88% are automatic.Everyyear 3 billion products are delivered to our clients, including Sony,TDK,Sankyo,JCI and Thyssenkrupp,etc.

Production Ability

Factory Photos

Item | Description |

Special Service | 1) drawing design.we can desgin drawing according to your requirements or sample.

2) various fabrication service. Our company has been specializied in metal stamping parts,plastic injection molding,etching metal,welding,punching also available. |

Unique Advantages | 1. 30+ years experience in metal stamping,plastic injection molding&etching metal.

2. Kindly accepting small order for the beginning.

3. Sample order can be finished in one week.

4. Top quality guaranteed by skilled workers,managing system and status of facilities.

5. We have many long cooperation suppliers.

6. 100% inspection before delivery. |

Wide Application | Our products have a wide use,such as motorcycle, bicycles, truck, equipment, electronic, amplifier, machinery, furniture and so on. |

Till now, customers visited our factory come from more than ten countries around the world.

Dear friends,

Dear friends,

Welcome to visit our factory for further communication!

We're always here waiting for your arrival.

Xianghang as a supplier of precision metal stamping services dates back to the company's origins in 1983. The company, considered one of the premier precision metal stamping suppliers, specializes in the stamping of tight-tolerance, close-pitch, high-precision and light-gauge metal components as well as thicker gauge, larger metal components and assemblies.

In providing precision metal stampings, we maintain a robust internal tooling capability to assure all of our progressive stamping tools exceed customer requirements. For progressive tooling design, we employ CAD packages such as AutoCAD, as well 3D packages such as PRO E and SolidWorks and UG. Each facility has surface grinding, programmable CNC centers, sinker EDM and wire cutting EDM technologies, in house to support our precision metal stamping operations.

Our stamping operations precision metal stamping presses, Materials used in the precision metal stamping process include Nickel, Tinned Copper, Beryllium Copper, Phosphorous Bronze, Stainless Steel, Copper, aluminum and Cold Rolled Steel with thickness ranging from 0.05mm to 3.0mm.

In addition to metal stamping, we have integrated a number of complimentary precision metal forming and metal joining processes such as welding and tapping and riveting into the stamping operations to reduce costs in certain applications. We also supply surface treatment such as electroplate, anodizing and Polish, etc.

Xianghang also offer plastic injection. Our highly skilled engineers and technicians work on our computerized injection moulding machines to ensure that each moulded part meets the product specifications of our customers. In order to cooperate metal stamping parts, and we supply assemble metal stamping & plastic injection.

Xianghang is dedicated to researching & developing and mamufacturing precision stamping moulds and injection dies over 30 years, its' annual output of over 3 billion pieces. The products are applied to automobiles, electronics & electrotechnics, communication equipments, household electrical appliances, instruments and meters, etc. And mainly sold to Japanese, American, Germany, Italian invested enterprises and other foreign invested enterprises as fittings.

Concerning product quality, the company has passed ISO9001 International Quality System Attestation in 2004 and ISO1400 Environmental Management System Attestation in 2005.

By virtue of adequate quality guarantee, favorable prices, short delivery time and advanced service concept, we would like to, on the road of seeking excellence, join hands and create a brilliant future together with friends home and abroad!