| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Phase: |

Single |

| Coil: |

Amorphous Alloy Transformer |

| Cooling Method: |

Oil-immersed Type Transformer |

| Winding Type: |

Two-winding Transformer |

| Application: |

Power |

Product Description

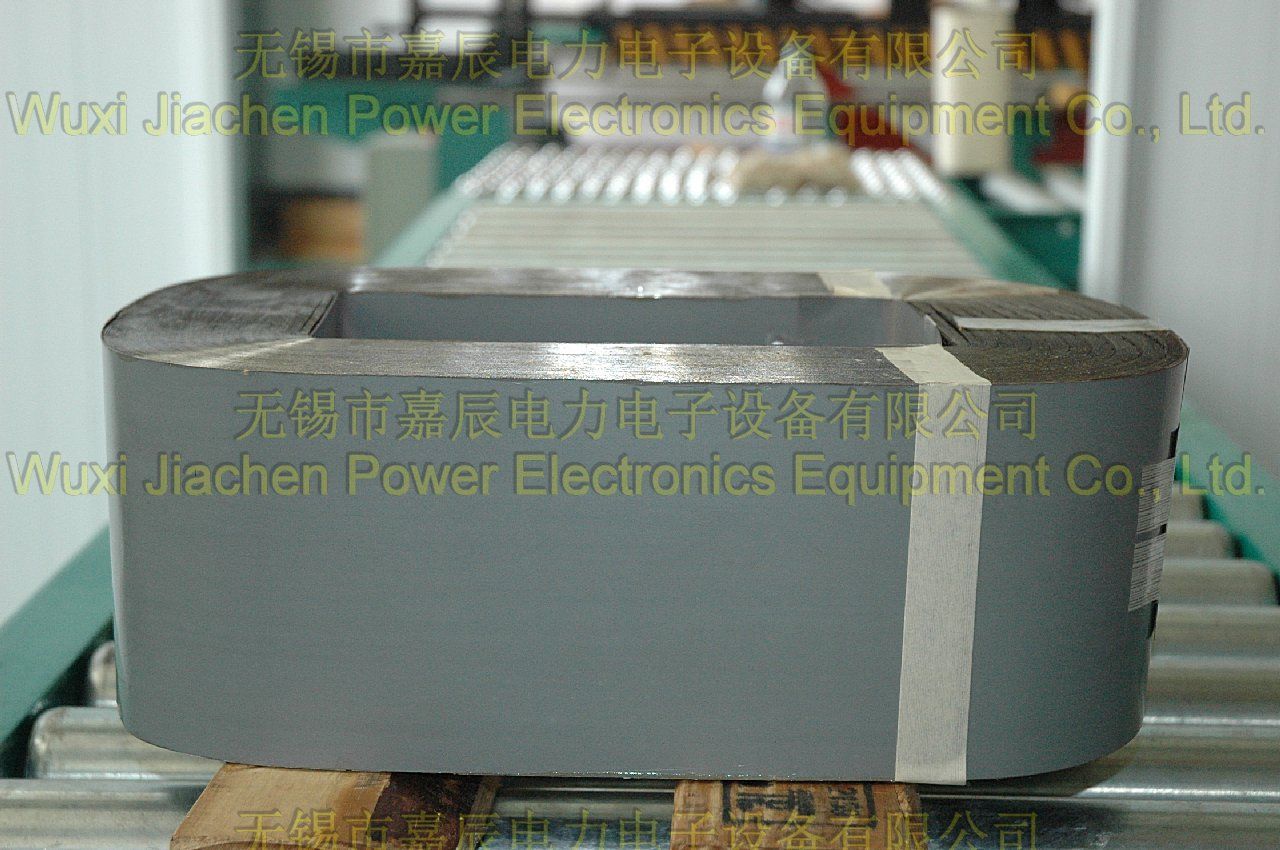

1, Introduction: Amorphous alloyOver the past several thousand years, the metals of alloys used by the human beings are all those materials with crystalline structure, where the atomic three-dimensional space is provided with ordered arrange to form a periodic lattice structure.When the amorphous alloy is rapidly cooled from the liquid state, because it can not crystallize in time and then will remain the liquid atoms in the condensed state of disordered arrangement at room temperature or low low temperature, the atoms will not be arranged in long-range ordered, periodical and ruled state but in long-range disordered state. The birth of amorphous alloys is also known as a revolution in metallurgy materials science.2, Processing technology of the amorphous transformer core

By using the amorphous alloys with prominent magnetic properties to manufacture the core and applied to the transformer, it will be anticipated to obtain a very low core loss. However, due to itself properties, this kind of core have many characteristics and need our attention during the design and processing. Mainly reflected in the following aspects.

a) Cutting: Amorphous alloy materials are very hard and it is quite difficult to cut with conventional cutting machine. So it should be taken in account to reduce the shearing volume when design.

b) Stacking: the thickness of the amorphous alloy is extremely thin and the surface of the tape is not even, so the fill factor of the stacked core is very low;

c) Molding: Due to amorphous material are very sensitive to the mechanical stress, so it is necessary to take a special tightening measures in the production process.

d) Annealing: In order to reduce the core loss, annealing procedure is very important, and it is also the crucial technology in the whole process.

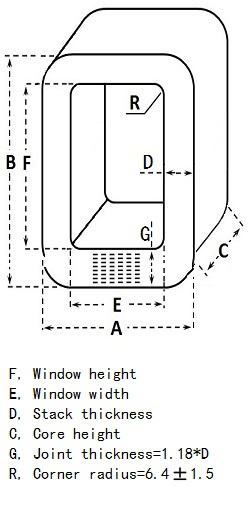

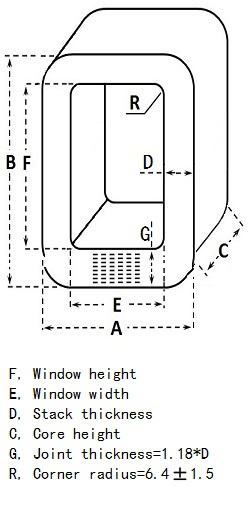

3, Structural features

Three phase five legs amorphous core is suitable for Dyn11 connection group transformer. The current design of existing core dimensions can meet the requirements regarding to our current assembly technology, facilities and craft ability during the amorphous transformer manufacturing.

By adopting the advanced distributed stacking structure in the core joint area, the stacked thickness normally less at least 7% compare to other competitors. And final reduce the whole transformer dimensions.

Lower exciting power could reduce the transformer noise during operation.

Wuxi Jiachen Power Electronics Equipment Co., Ltd. is established in 2014, located in Wuxi city. The transportation is very convenient, it will only take you about 15 minutes from Wuxi East super-speed railway station, and about 20 minutes from Wuxi ShuoFang airport.

With the support of our contracted partners, we have our own manufacturing base and R&D center. So we positioned our company as a professional sales company, provide our customers with the superior products and services; We warmly welcome our customers to visit our company to talk about the cooperation details, and discuss the innovative design of our products to enhance our mutual competitiveness.

Now, our company devote our efforts to export the products below:

All kinds of distribution transformer wound cores, like S11-100kVA, S13-100kVA; Single phase wound core like D9, D10, D11 etc. For pole mounted transformers or pad mounted transformer, we could also produce three phase transformer wound cores; The capacity could be 10kVA to 2500kVA; For some clients, we could also design the drawings as per your technical parameters.

All series of toroidal cores, C type cores, CD type and E type cores; Widely used in potential transformer, instrument transformer, voltage transformer, current transformer, power transformer, some reactors and autotransformer and so on.

Various and types of series reactor, inductor, DC reactor for Frequency converter, filter reactor, triangle start reactor, starting compensator, autotransformer, LV dry-type transformer, current transformer for distribution cabinet, bushing type current transformer etc.

Our company now cooperated with my partners to develop the Uni-cores market in China and the finished products is operating soundly in our end users. We sincerely and warmly welcome you to join us to study new technology to improve our products performance, reduce manufacturing cost, and benefit mutually.