CNC Machine Heat Sink Transformer Heatsink Factory

| Price: |

US $ 10-100/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union |

| Cooling Way: |

Self-Cooling, Air-Cooling, Water-Cooling |

| Drilling: |

CNC Drilling |

| Lenght: |

Customerized or General |

| Width: |

Customerized or General |

| Power: |

High Power |

| Material: |

Aluminum Alloy 6063 |

| Type: |

Aluminum Profiles |

| Surface Treatment: |

Anodic Oxidation, Sand Blasting, Blackening, etc. |

| Technique: |

Extruded |

| Certification: |

SGS, ISO9001:2008, GB/T |

Product Description

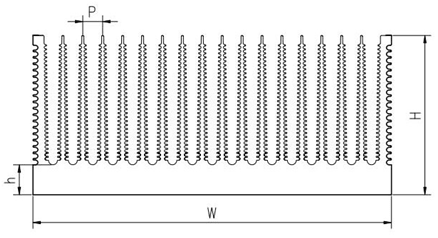

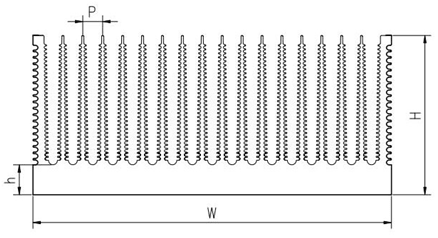

P

Product Description | Product Name | Tower-Shaped Heat Sink of High Radiating Power |

| Product Catalogue | Tower-shape, Bamboo-shape, Dense teeth, Silicon Controlled Rectifier, General profiles, Combined profiles, Insert, Shovel, Heat tube, Liquid-cooling, LED lamps, Water-cooling casting, Non-standard special series and Auto special series. |

| Deatiled Sizes | Customized/On Request |

| Production Process | Metal Extrusion, Cutting, CNC Processing, Milling, Drilling, Cleaning, Inspecting, etc. |

| Surface Treatment | Anodic Oxidation, Sand Blasting, Blackening, Polishing, etc. |

| Application | Welding Outfit, LED Lamps, Inverter, Communication Device, Power Supply Equipment, etc. |

| Packing | Foam, Carton, Wooden Box |

| Reference Standard | GB/T 14846-2008 |

| Experience | 31 Years Professional Manufacturing Experience |

| Trade Term | CIF, FOB, EXW, etc. |

| Payment Term | T/T, L/C |

| Delivery Time | Normally 7-15 working days after deposit received |

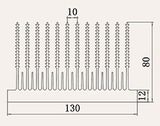

Product Photo Heat Sink SpecificationSpecification of Tower-Shape Profiles Heat Sink

Heat Sink SpecificationSpecification of Tower-Shape Profiles Heat Sink

(More sizes and other series are on request)Tower-Shape

Aluminum Profiles

Heat Sink |  |

| Model NO. | W(mm) | H(mm) | h(mm) | P(mm) | Density

(kg/m) | Wind

Resistence

(%) | Testing Wind

Speed(m/s) | Heat Resistance

(200mmºC/w) |

| XHX765 | 502 | 102 | 19 | 7.5 | | 39 | 6 | 0.0117 |

| XHX721 | 320 | 102 | 18 | 7.5 | 40.4 | 42 | 6 | 0.0194 |

| XHX769 | 502 | 102 | 22 | 10 | 633.1 | 29 | 6 | |

| XHX788 | 320 | 99 | 18 | 11.4 | 16 | 26 | 6 | |

| XHX1001 | 440 | 122 | 24 | 12 | | 30 | 6 | |

| XHX974 | 300 | 81.5 | 16 | 10 | 29.2 | 26 | 6 | |

| XHX1003 | 380 | 122 | 24 | 12 | | 30 | 6 | |

| XHX861 | 290 | 90 | 18 | 10.6 | 30 | 27 | 6 | |

| XHX1002 | 320 | 122 | 24 | 12 | | 30 | 6 | |

| XHX852 | 290 | 70 | 13 | 9.6 | 24.9 | 29 | 6 | |

| XHX4 | 280 | 100 | 19 | 11.2 | 31.2 | 26 | 6 | |

| XHX30 | 262 | 60 | 12 | 9.2 | 17.8 | 28 | 6 | 0.0488 |

| XHX779 | 280 | 80 | 15 | 10 | 23.6 | 26 | 6 | 0.0491 |

| XHX2 | 260 | 100 | 18 | 11.2 | 29.2 | 27 | 6 | 0.0422 |

| XHX10 | 280 | 60 | 12 | 9.2 | 19.6 | 28 | 6 | 0.0494 |

| XHX775 | 260 | 80 | 16 | 10 | 24 | 24 | 6 | |

| XHX860 | 270 | 60 | 16 | 10.6 | 28 | 27 | 6 | |

| XHX859 | 250 | 90 | 16 | 10.6 | 24.4 | 27 | 6 | |

| XHX851 | 270 | 70 | 13 | 9.6 | 23.2 | 29 | 6 | |

| XHX981 | 250 | 75 | 16 | 10 | 19.3 | 25 | 6 | |

| XHX850 | 250 | 90 | 13 | 9.6 | 21.6 | 29 | 6 | |

| XHX982 | 247 | 65 | 14 | 9.5 | 22.6 | 27 | 6 | |

| XHX522 | 240 | 101 | 15 | 13.4 | | 18 | 6 | 0.0504 |

| XHX153 | 243 | 60 | 12 | 9.2 | 16.9 | 28 | 6 | 0.0562 |

| XHX983 | 240 | 95 | 18 | 12 | 24 | 23 | 6 | |

| XHX778 | 240 | 80 | 15 | 10 | 22.4 | 26 | 6 | 0.0447 |

| XHX773 | 240 | 101.5 | 18 | 11.4 | 28.4 | 25 | 6 | |

| XHX980 | 231 | 85 | 16 | 11 | 21.1 | 24 | 6 | |

| XHX858 | 230 | 90 | 16 | 10.6 | | 25 | 6 | |

| XHX774 | 220 | 80 | 16 | 10 | 19.8 | 26 | 6 | 0.0424 |

| XHX849 | 230 | 70 | 13 | 9.6 | 18.5 | 29 | 6 | |

| XHX857 | 210 | 90 | 16 | 10.6 | 20.6 | 27 | 6 | 0.0543 |

| XHX848 | 210 | 70 | 13 | 9.6 | 17.1 | 29 | 6 | 0.0492 |

| XHX154 | 225 | 60 | 12 | 9.2 | 16.9 | 28 | 6 | |

| XHX961 | 210 | 70 | 13 | 9.6 | 25.4 | 21 | 6 | |

| XHX827 | 220 | 100 | 18 | 10.8 | 23.9 | 27 | 6 | |

| XHX239 | 207 | 76 | 16 | 10.2 | 17.7 | 27 | 6 | 0.0477 |

| XHX5 | 206 | 100 | 16 | 10.7 | 22.6 | 28 | 6 | 0.0386 |

| XHX776 | 200 | 80 | 15 | 9.9 | 18.8 | 26 | 6 | 0.0402 |

| XHX155 | 206 | 60 | 12 | 9.2 | 14.5 | 28 | 6 | 0.0535 |

| XHX829 | 200 | 60 | 12 | 9.3 | 13.4 | 28 | 6 | 0.057 |

| XHX772 | 190 | 95 | 15 | 11.2 | 19.2 | 26 | 6 | 0.0619 |

| XHX828 | 200 | 100 | 18 | 10.8 | 21.3 | 27 | 6 | 0.0431 |

| XHX856 | 190 | 90 | 16 | 10.6 | 19.9 | 27 | 6 | 0 |

| XHX917 | 200 | 86 | 20 | 9.8 | 19.7 | 26 | 6 | 0.0556 |

| XHX847 | 190 | 70 | 13 | 9.6 | 15.5 | 29 | 6 | 0.0571 |

| XHX158 | 188 | 60 | 12 | 9.2 | 13.36 | 28 | 6 | 0.0615 |

| XHX855 | 170 | 90 | 16 | 10.6 | 17 | 27 | 6 | 0.0593 |

| XHX771 | 180 | 100 | 16 | 11.2 | 19.5 | 25 | 6 | 0.0517 |

| XHX846 | 170 | 70 | 13 | 9.6 | 14.8 | 29 | 6 | |

| XHX777 | 180 | 80 | 17 | 10 | 17 | 24 | 6 | 0.0432 |

| XHX830 | 160 | 100 | 18 | 11.2 | 17.2 | 26 | 6 | |

| XHX717 | 180 | 76 | 16 | 9 | 28 | 36 | 6 | |

| XHX831 | 160 | 80 | 15 | 10 | 15 | 26 | 6 | 0.0586 |

| XHX832 | 160 | 60 | 12 | 9.1 | 23.9 | 29 | 6 | 0.0622 |

| XHX844 | 130 | 70 | 13 | 9.6 | 10.9 | 29 | 6 | |

| XHX854 | 150 | 90 | 16 | 10.6 | 15.9 | 27 | 6 | |

| XHX845 | 150 | 70 | 13 | 9.6 | 13.1 | 29 | 6 | |

| XHX300 | 120 | 100.5 | 15 | 10 | 13.7 | 28 | 6 | 0.0559 |

| XHX853 | 130 | 90 | 16 | 10.6 | 13.2 | 27 | 6 | |

| XHX486 | 130 | 60 | 10 | 11 | 7 | 30 | 6 | |

| XHX488 | 130 | 60 | 10 | 9.5 | 7.6 | 32 | 6 | |

| ... | | | | | | | | |

Parameters

| Weldability | Cutability | Corrosion Resistance | Conductivity | Density (20ºC)

g/cm3 |

| Good | Very Good | Good | 209 | 2.7 |

Tensile strength

(20ºC,MPa) | Yield Strength

(20ºC,MPa) | Hardness | Ductility

(1.6mm/16in) | Max Shearing Strength(MPa) |

| 185 | 145 | 60 | 12 | 115 |

Company Introduction Chengdu Xihe Heatsink Factory

Company Introduction Chengdu Xihe Heatsink Factory

Chengdu Xihe Heatsink Factory was built in the mid-1980s, construction area of more than 10,000 square meters, specialized in manufacturing aluminum Heat Sink for power semiconductor device, undertaking all kinds of heatsink` design, production and sales.

At present, from mold-designing, mold-making, profiles-extruding, machinery-processing, testing thermal resistance, making thermal image, optimizing the design of power dissipation to finished heatsink, all solely completed by our factory, thereby greatly reducing the supply cycle and improving product quality to meet the users` demand better.

Our advantages

At present, the enterprise has become a leading enterprise and created "Nine of the most" in the domestic counterparts.

- Design ability is the strongest

- Maximum machining equipments

- Extrusion equipment is the most advanced

- Welding equipment is the most advanced (no welding accessories)

- The widest processing size at one time (800mm)

- The longest perimeter extruded at one time (14,000mm)

- The most new products (Several hundreds)

- The biggest solo product power (Wind-cooling heatsink 20,000W, liquid-cooling radiator 10,000W.)

- The best testing equipment (Wind-resistant and heat-resistant curve testing machines), with the ability of producing heatsinks more than 3,000 tons annually.

Feature

1. Materials: standard aluminum alloy 6063

2. Efficient heat dissipation.

3. Provide one-stop efficient cooling solution for heat sink.

4. Provide customized design or model section service.

5. Our own factory with more than 10000 square meter and professional R&D team.

6. High quality, competitive price, best service.

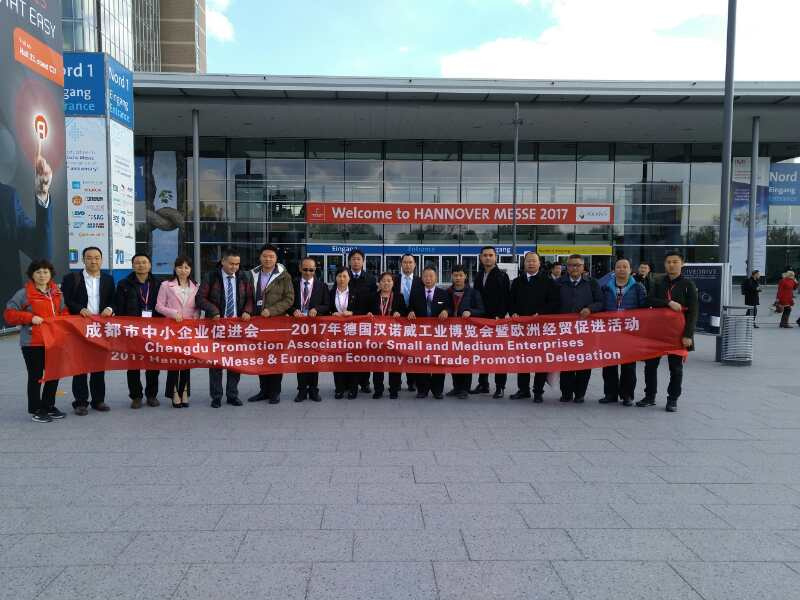

Attend 2017 Hanover Messe

FAQ

1, Are you a trading company or manufacturer ?

We are a manufacturer/factory over 30 years wellknown in China.

2, What kind of industries your heat sinks are used in ?

Welding Outfit, Power Supply Equipment/Charger, LED Lamps, Inverter, SVG & APF Radiator, New Energy Car, etc.

3, How to guarantee your product quality ?

We have strict quality control and management system to guarantee our products before, during and after production. Also we accept customer test and the Third-party report.

4, How about visiting your factory ?

Yes, all partners and customers are welcomed to visit our factory.

Contact information

Foreign Sales Department_Chengdu Xihe Radiator Factory

Tel: +86-28-84830346 88467530

Fax: +86-28-84861161

No.429 Luosi Road, Xihe Industrial Park, Longquanyi District, Chengdu City, Sichuan Province, China, 610107

Website:http://en.xhsrq.com

Product E-catalog:http://en.xhsrq.com/product.html

Chengdu Xihe Heatsink Factory is established in MID-eighties, located in Xihe Industrial Zone, Chengdu city, covering an area of 10000m2. We are specialized in producing radiators used in semiconductor, such as welding machine, LED, APF and so on. Our factory has established a full range of business scope, including R&D, manufacture, sale and service, so we can provide customized products.

These years, we always believe that quality, safety and technology are the most important for us. Our target is to be the first. We created many miracles these years and play important part in high-power component of electronic element in our country. Currently, we are in the leading position of the radiators, and we can produce at least 4000 tons radiators per year.

At present, XHSRQ have become the leading domestic counterparts, and created the domestic counterparts, " Nine of the most":

1, Design ability is the strongest.

2, The quatity of machining equipments is the most.

3, Extrusion equipments are the most advanced.

4, Welding equipments are the most advanced. (No welding accessories)

5, Processing size is the widest at one time. (800mm)

6, Extruded perimeter is the longest at one time. (14, 000mm)

7, The quantity of new products is the most. (Several Hundreds)

8, Solo product power is the biggest. (Wind-Cooling heat sink 10, 000W, Liquid-Cooling heat sink 30, 000W, Thermostatic water-cooling heat sink 200, 000W)

9, Testing equipment is the best (Wind-resistant and heat-resistant curve testing machines), with the ability of manufacturing heat sinks more than 3, 000 tons annually.

Our company applies K3 and CRM system to the management, and all of the products we manufactured has accredited with ISO9001: 2008 quality management system certification, and attained the domestic CQGC(China Light Industry Products Quality Guarantee Centre) certification. Our products conclude following types: New combined heat sink, combined heat sink, tower-shaped heat sink, dense tooth heat sink, inserted tooth heat sink, hot-pipe heat sink, LED rheat sink, new-energy heat sink, APF heat sink and so on.

More >

Other Products with This Manufacturers