Construction Hoist Three Phase Asynchronous Motor

| Price: |

US $ 500/Set |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

2/Set |

| Pay Type: |

L/C,T/T,Western Union,Paypal |

| Prod Model: |

YZZ132M |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Power: |

11kw, 15kw |

| Voltage: |

380V |

| Frequency: |

50Hz |

| Protection Class: |

IP44 |

| Number Of Stator: |

Three-Phase |

| Function: |

Driving |

| Application: |

Construction Hoist |

| Speed: |

1390rpm |

| Starting Mode: |

Electric |

| Brand: |

Jinnuo, Zhangjiang |

| Certification: |

SGS |

Product Description

1. Overview

Circular cylindrical worm gear worm drive compared with the general contact line shape is conducive to the formation of hydrodynamicoil film. Low oil, anti-bonding ability, smooth, vibration, low noise, high transmission efficiency, good process performance,circular cylindrical worm gear is the country that promote the use of high-tech products, circular cylindrical worm reducer mechanicalCommission designated replacement products, has developed there GB9147 ~ 88 standardseries worm gear. Suitable working environment temperature -40 ºC ~ + 40 ºC oilinput speed is not greater than 1500 rev / min, the worm can be positive and negative direction.Electric construction elevator / building hoist motor

2. General Status:

Comparing with general worm transmission, Arc-column worm transmission's contact linc benefits to dynamic pressure oil mcmbranc' s generation. During operation, lower oil temperature, stonger anti-agglu-dination capacity, stablc work, less shake, lower norse, higher transmission efficiency, excellent proccss technology. Mine, lifting, chemicals, light industry, construction ctc. It is substitute of the general speed redueers used for above in dustrics. The suitable work temperature is among-40ºCtill+40ºCinput speed is less than 1,500 rpm, worm could turn in forward and backward dircctions.Electric construction elevator / building hoist motor

| Electric construction elevator / building hoist motor |

Reducing

speed ratio

(i) | Distance

bctwccn two

shafts(mm) | Input Speed

(r/min) | Input

efficicncy

(KW) | Target input

Torque

(NM) | General

Transmission

efficiency(%) |

| 8.25 | 125 | 1500 | 17.6 | 895 | 91 |

| 144 | 1500 | 25.6 | 1185 | 89 |

| 10 | 125 | 1500 | 14.9 | 890 | 90 |

| 144 | 1500 | 19.7 | 1130 | 88.3 |

| 12 | 125 | 1500 | 12.4 | 1068 | 89 |

| 144 | 1500 | 17.1 | 1088 | 88 |

| 14 | 125 | 1500 | 11.72 | 895 | 89.4 |

| 144 | 1500 | 16.33 | 1180 | 87 |

| 16 | 125 | 1500 | 11.6 | 1000 | 88 |

| 144 | 1500 | 15.56 | 1296 | 86 |

| 20 | 125 | 1500 | 9 | 1010 | 87 |

| 144 | 1500 | 12.46 | 1296 | 85 |

| 25 | 125 | 1500 | 6.9 | 930 | 84 |

| 144 | 1500 | 9.44 | 1234 | 83.5 |

3. Installation, operation and maintenance of secd reducer:

Electric construction elevator / building hoist motor

a) Speed reducer should be installed on a stable place where it's convenient to fill or drain oil and good air circulation;

b) The original driver and working machine of speed reducer must be centralized, and the tolerance can't exceed acceptable data of coupler.

c) After installation the speed reducer could work flexible when turning by hand, no block.

d) After installation, speed reducer must have trial run without load before formal use, when the trial running successfully, then have trial with load as the following steps:

. With 25% of designed loading;

. With 50% of designed loading;

. With 100% of designed loading;

When every step trial run, wait the temperature reach to the balance point, and no less than 2 hours; the highest oil temperature can' exceed 100ºC;speed reducer run stably; no shock or noisc; lubricate weel, all sealing points and contact surfaces have no lcak.

e) Preventive maintenance should be applied regularly, once any scratches or agglutinations were found, they must be climinated effeetively, All spare parts must be manufactured as standard to cnsure good quality, Renewed spare parts can,t be uscd until trial with load is executed.

| Electric construction elevator / building hoist motor |

| Motor Type | Cage | Capacity(kg) | Speed(m/min) | Motor(kw) |

| SC200 | single | 2000 | 36 | 3*11 |

| SC200/200TD | double | 2000*2 | 36 | 2*3*11 |

| SC100 | single | 1000 | 36 | 2*11 |

| SC100/100TD | double | 1000*2 | 36 | 2*2*11 |

| SC150 | single | 1500 | 36 | 2*11 |

| SC150/150TD | double | 1500*2 | 36 | 2*2*11 |

| SC270 | single | 2700 | 36 | 3*15 |

| SC270/270TD | double | 2700*2 | 36 | 2*3*15 |

| SC320 | single | 3200 | 36 | 3*18.5 |

| SC320/320TD | double | 3200*2 | 36 | 2*3*18.5 |

| VFD device is optional,the speed:0-36m/min,0-63m/min,0-96m/min |

| Can be customized according to customers' demand |

4. Storage condition

Electric construction elevator / building hoist motor

Speed reducer could be stored indoor for 30 days, fill up speed reducer with recommended lubrication oil, and use bolt to replace acrator. Turn around couple set worm once very 30 days in order to protect oil scaling and bearing. When working, lubrication oil depth should be reduced to the corrct position, and acrator be re-installed. If the speed reducer had been stored indoor over one year or need to be removed to outdoor, machine supplier company should be contacted, and ask for extra user manual.- If there is no oil inside spced reducer, woum wheel oil of N320 must be filled to correct oil positi on level as regulation before running. Under special ease(if can found oil of N320. N320 gear whecl oil be permitted to use also), working load and transmission efficiency of speed reducer dccreasel.

- b) N320 worm wheel oil and N320 gear wheel oil can be mixed together.

c) Without permission, installed speed redueer can be dismanted.

FAQ

Q: Brand?

A: RUIBIAO, We also cooperate with Potian, Liebherr, SYM, SCM, Yongmao, GJJ, Baoda and etc.

Q: Delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment.

Q: Quality assurance?

A: 100% original parts, 1 year of quality guarantee.

Q: Advantage?

A:(1) 12 years experience's supplier specialize in tower crane parts, professional engineers team at your request in time.

(2) Bulk parts storage, shorten delivery time.

(3) Special discount for you, as we have stable parts supplier for years.

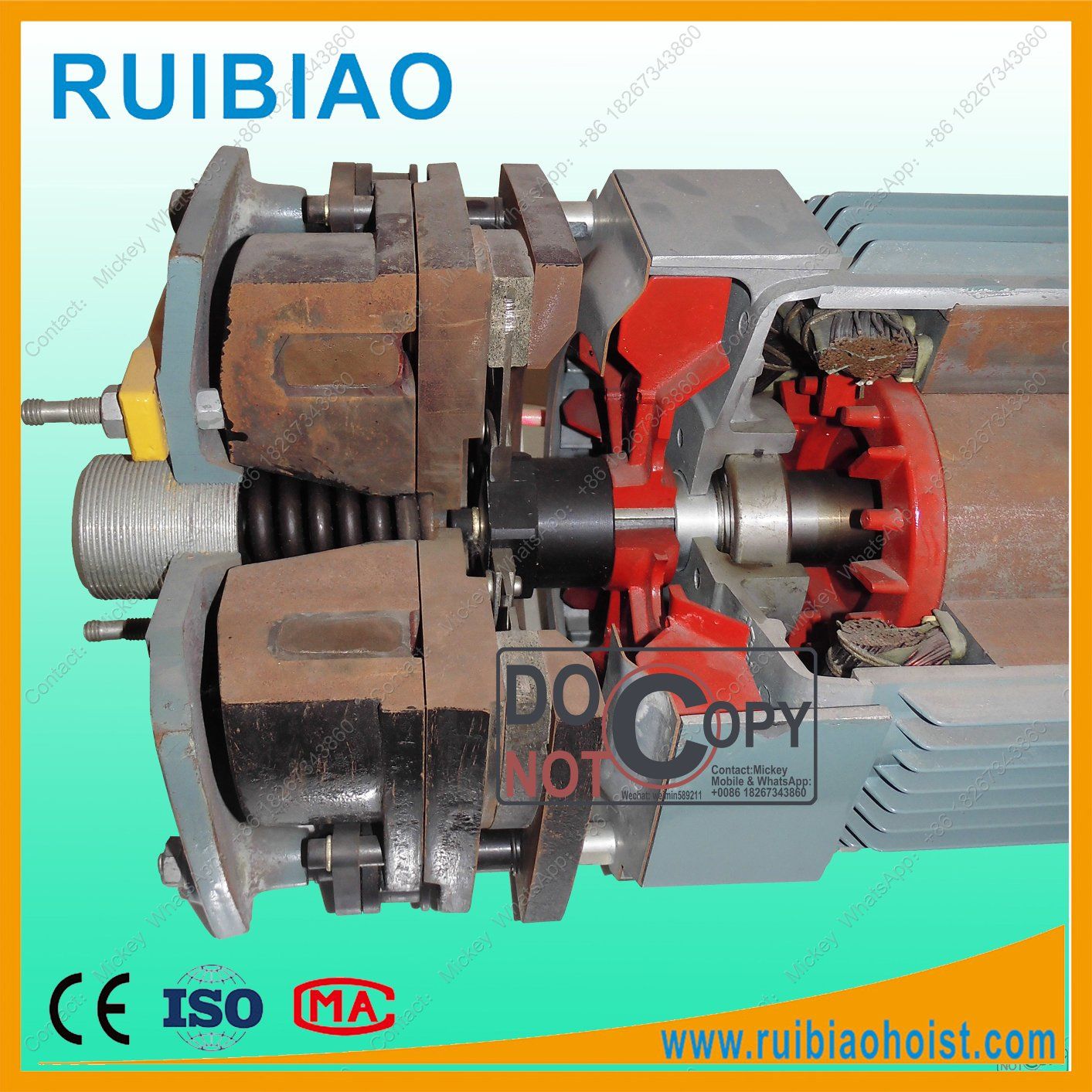

Brief Introduction of the Product

1. Automatic Adjustment: the electromagnet can adjust automaticly the space between the armature and itself.

2. Raises and stops steadily

The motor of YZEJ series is used in hoist mechanism of construction elevators. It's advanced abroad and in China because according to the degree of brake disc, the electromagnet on the brake system can adjust automaticly the space the armature and itself. It owns simple structures, so it's very convenient for workers to use. It raises and stops steadily, which reduces the impulse force to the mechanical equippment, so it helps you save the money to protect.

| | YZEJ |

| | 132M-4 | 132L1-4 | 132L2-4 | 132L3-4 | 132L1-8 |

| Rated power(KW) | 11 | 15 | 16.5 | 18.5 | 7.5 |

| Rated speed(r/min) | 1395 | 670 |

| Vultage rating(V) | 380 |

| Rated currrent(A) | 23.5 | 32.2 | 34.4 | 37.8 | 19 |

| Rated frequency(Hz) | 50 |

| Rated load torque/locked rotor | 2.6 |

| Insulating class | F |

| Locked rotor current(A) | 136 | 220 | 235 | 252 | 80 |

| Connection | Y |

| Brake torque(Nm) | 120 | 170 | 210(170) | 210 | 170 |

| Weight(kg) | 91 | 115 | 130 | 145 | 115 |

| Protective class | Motor IP55 | Brake IP23 |

Features of building elevator/lift /hoist

Compact design and comfortable operating experience.

Single or double cage configurations.

Design without counterweight.

Use perforated aluminum plate as a decorative plate of the cage.

Galvanize Mast section offered.

Wide range of optional equipments and functions.

Competitive factory price

Move by good quality rack and pinion

Stable platform lift

Basic technical parameters of industrial material hoist

building lift elevator capacity : 1000kg - 5000kg,

building lift elevator working height: 50m-450m,

Common and VFD elevator speed: 36m/min-96min/m.

building lift Elvator mast section with rack and pinion: painted and galvanized style.

Main technical parameters for common models:| Characteristic | Model | Rated Loading | Lifting Speed | Motor Power |

Double cabin | SC200/200 | 2×2000kg | 33m/min | 2×(3×11kw) 2×(2×13kw)

2×(2×15kw) |

| SC150/150 | 2×1500kg | 33m/min | 2×(2×15kw) |

| SC100/100 | 2×1000kg | 33m/min | 2×(2×11kw) |

Single cabin | SC200 | 2000kg | 33m/min | 3×11kw

2×13kw

2×15kw |

| SC150 | 1500kg | 33m/min | 2×15kw |

| SC100 | 1000kg | 33m/min | 2×11kw |

Production details:

1. Production process: Strict material selection- blanking- inspection - welding- inspection- Blasting - inspection -Baking finished or galvanized- inspection - Finished Product

2. The product can be customized according to customers'requirements (drawing, specifications and so on).

A: Cage Details.

1.The cage is boarded up by all punched aluminum sheet ,Sidewall of Wire Mesh for cage is also avaliable. The sizecan be arranged to your requirement

2. Main structure of cage is made of high-quality steel after bending.(The bended steel is firm, good verticality, stability. Moreover it ensure stable of the whole structure)

B: The Mast section(color is variable) is made of seamless pipe.(The high quality seamless steel pipe is good verticality, anti-pressure, anti-aging, thickness and so on)

C: Completed safety measures

1. Equiping with Anti-falling govenor

2. Electrical an Mechanical interlock: Door safety switches, Slack rope switch

3. Safety hook

4. Upper and bottom limit swithes, trap door limit switch

5. Overload protector

6. Bottom Buffer

7. Level Calling system and auto leveling device to be choose.

Shanghai RuiBiao Construction Machinery Co., Ltd is the special maker of power precision transmission products of gear racks, slewing ring bearings, safety devices and gearboxes, Anemometer Wind Speed Meter, Overload Indicator and Sensor, Worm and Worm Wheel, Hoist Spare Parts for construction, engineering, lifters, lifting elevators, hoists, and machinery transmission. Our products are mainly exported to Malaysia, Italy, the USA, Spain, Greece, Turkey and Russia. We can satisfy our customers' needs well. We can produce products according to customers' special requirements.

We are making precision casting parts according to customer's technical requirements

We sincerely hope to cooperate with friends in the fields!

CEO STATEMENT

In the year of 2003 I started construction machine business in Shanghai.

This is a young industry, at that time 30 sets of passenger hoist/month was called huge quantity.

I was invited to start this business in the year of 2003. Rapid growth comes after that, together

With series of challenges.

I always say that making good machine costs a lot. I tried to give convenience to our client, save

Their time for searching, offer them one stop solutions. While I like to stay together with our engin

Er to produce premium products. Bring benefits to business partness and operation the company

For sustainable development. I consider it great fun.

Developing new kinds of product is suitable for new market demands, our target is to grow in re

Sponsible way, Looking ahead, we are entering the next phase of implementing our soical respon

Sibility. Our focus have been and will be on improving our product performanceand increasing our

Market share. An important element going forward will be to work more closely with our distributors

In order to identify sustainable solutions together.

At Shanghai Ruibiao, we thirst for great. We never settle and always want to be better. I would like

To invite you to share your views on how and where we can do better.

Cheers,

Angela

More >

Other Products with This Manufacturers