| Prod Model: |

MJ-9334 |

| Formation Methods: |

High Temperature and High Pressure |

| Delivery: |

7-10 Working Days |

| Size: |

Customized |

| Samples: |

Free Samples Are Welcome |

| Customizable: |

Yes |

| MOQ: |

1 Piece |

| Temperature: |

High Temperature |

| Application: |

Generator |

| Chemistry: |

Hybrid Insulation |

| Material: |

Fiberglass |

| Maximum Voltage: |

>100KV |

| Type: |

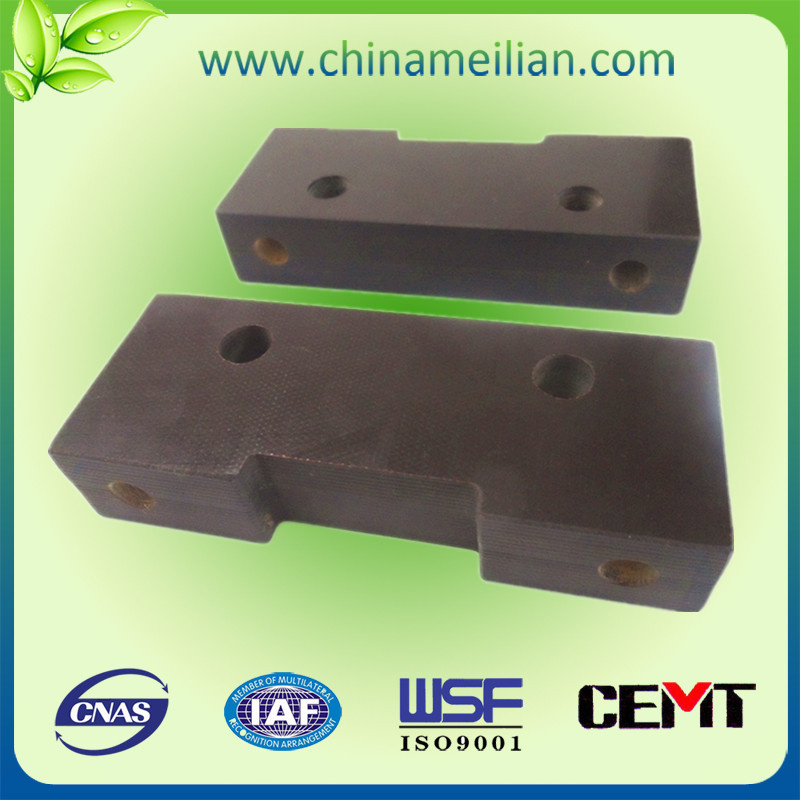

CNC Parts |

| Thermal Rating: |

B, B-F, F, H |

| Brand: |

Mj |

Product Description

Features:

Defferent heat grades

Excellent mechanical and electrical properties

Customized specification acceptable

Less tolerance

Application:

Insulation part, insulation accessories

Electrical components, electrical transformer part

Knife switch bottom board, electrical accessories

Electrical transformer part, knife switch bottom board

Insulation clamps, Other insulation processing parts

| Basic information |

| Product name | Processed Electrical Insulation Compenents |

| Brand | MJ |

| Material | The same with the original laminates' materials |

| Grade | B, B-F, F, H |

| Feature |

Defferent heat grades

Excellent mechanical and electrical properties

Less tolerance |

| Application |

Insulation part

insulation accessories

electrical component

electrical transformer part

knife switch bottom board

electrical accessories

electrical transformer part

knife switch bottom board

insulation clamp

Other insulation processing parts |

| Basic information |

| Product name | BMI Electrical Insulation Laminted Sheet/Prepreg |

| Item No. | MJ-9334 |

| Brand | MJ |

| Material | BMI resin and Alkali free fiberglass cloth |

| Grade | Grade H |

| Feature |

| Excellent mechanical & electric property Good heat & moisture resistance Easy for processing & machining |

| Application |

| Can be processed into high temperatue insulating structural parts installed in a variety of motors and electrical equipmenst, or processed into motor slot wedges, standard and non-standard shaped parts |

| Technical Performance |

| Density | ≥1.7g/cm3 |

| Appearance | Natural color Dark brown, surface smoothly without bubble and impurities, no flow marks, Cutting edge without fault and separation |

| Sheets Thickness | 0.1-50mm |

| Size | ≥1220x980mm |

| Formation methods | High temperature and high pressure |

| Thermal stability in 24h | ≥220ºC |

| Water absorption | ≤1.0% |

| Impact strength parallel to layer (Charpy method) | ≥147 KJ/m2 |

| Tensile strength | ≥120 Mpa |

| Flexural strength perpendicular to layer at room temperature at high temperature 180±2ºC | ≥400 MPa ≥200 MPa |

| Electric strength,perpendicular to the layer(at 90ºC±2ºC oil.) 0.5-1.0mm 1.1-2.0mm 2.1-3.0mm | ≥22 MV/m ≥20 MV/m ≥18 MV/m |

| Dissipation factor Under 48Hz~62 Hz Under 1MHz. | ≤0.08 |

| Voltage resistance parallel to layer (at 90ºC±2ºC oil for 1min) | ≥30 kV |

| Insulation resistance parallel to the layer . At room temperature Immersing in water for 24h | ≥1.0×104 MW ≥1.0×102 MW |

| Volume resistivity At room temperature Immersing in water for 24h 180ºC±2ºC | ≥1.0×105 MW/m ≥1.0×103 MW/m ≥1.0×103 MW/m |

| Surface resistivity At room temperature Immersing in water for 24h 180ºC±2ºC | ≥1.0×106 MW ≥1.0×104 MW ≥1.0×104 MW |

| Reference Standard | GB/T1303.1-1998 |

FAQ:

(1) Can you give me a discount price?

Answer: It is depending on the volume. The larger the volume is, the more discount you can enjoy.

(2) Why is your price a bit higher than other Chinese suppliers?

Answer: To meet the requirement of different customers and areas, our factory manufactures various kinds of quality for each item at a wide range of price. We can offer the products of different quality levels depending on customer's target price and quality requirement.

(3) How can I get a sample?

Answer: Normally small samples (sizes not larger than 300*300mm) can be sent free of charge and customers just need to bear a little shipping charge, or you can provide your DHL, FEDEX, EMS, UPS courier account number to us. For bigger sizes, it depends.

(4) How can you guarantee the quality of mass production is same with the sample sent to me before?

Answer: Our warehouse staff will leave another same sample in our company, with your company name marked on it, which our production will be based on.

(5) How can you deal with quality issues that customer feedback after receiving the goods?

Answer:

1) Customers take photos of unqualified goods and then our sales staff will send them to Engineering Department to verify.

2) If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in coming orders.

3) Finally, we will negotiate with our customers to make some compensation.

Our company is in Xi' An high tech Development Zone, mainly producing magnetic/electrical insulation laminates, slot wedges, thermal expansion materials, insulation varnish, impregnated cloth, insulation tube/sleeve/rod and etc. Our products are widely used in the fields of wind & thermal power, aviation, railway, military power transmission, motors and transformers and etc.

We have experts in R&D group which ensure the continuity and stability of the product quality and cost. The issued testing results apply to domestic and internaltional standards.

Our company covers 5000 square meters with 4 production departments: Magnetic board, Insulating materials, High voltage electrical appliance, CNC and slot wedge processing. WIth more than 50 sets of reactor, gluing machine, large-scale equipment, hot press, high vacuum impregnation and testing equipments, our annual production capacity can totally reach 800 tons.

We are founded in 2006. By 2007-2008, we passed 9001-2000 certification, Xi' An city Science and Technology Bureau identified us as "the city of Xi' An high-tech enterprises".

The spirit of our company is: "Good Reputation, Best Products, Wonderful Services