| Prod Model: |

GS-LFD3015 |

| Power Source: |

Dkj2000p |

| Size: |

3000*1500 |

| Spectroscopic Type: |

Prismatic Decomposition |

| Prism Rotating Speed: |

30000 |

| No. Of Spindle Mirror: |

24,36,48 Optional |

| Max. Perforating Speed: |

8640,000/Min |

Product Description

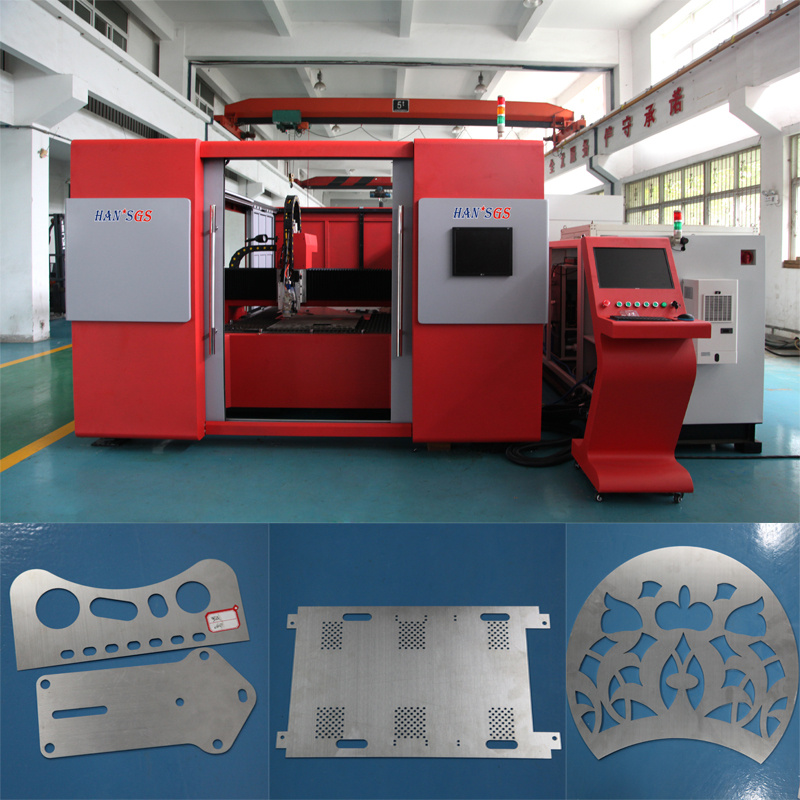

Factory price cnc laser machine/ metal laser cutting machine price

Functions of GS-LFD3015 laser cutter

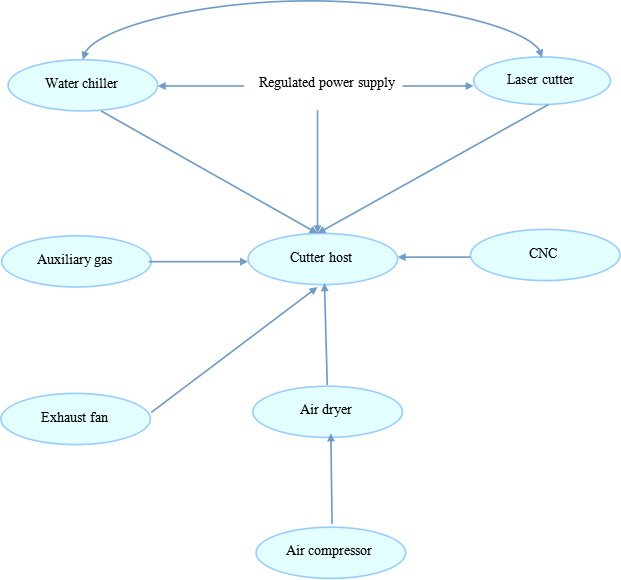

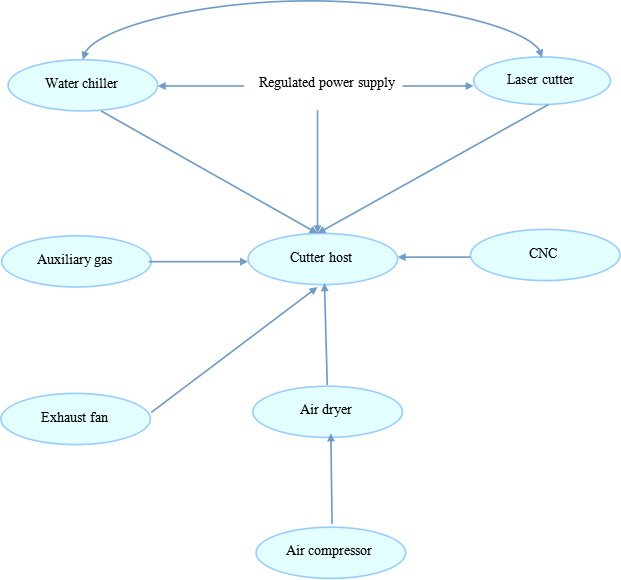

1. Equipped with exhaust device, have good exhausting effect and little pollution.

2. Small occupied area, high system integration, convenient to operate and maintenance,24 hours continuous working.

3. The water chiller has good safety protection function, such as over temperature, lack phase, pressure, water-break, undervoltage, overload, etc. With stable performance, satisfied the cooling requirement of laser source.

Laser cutting advantages over other thermal cutting methods

1. The cutting quality is good

2. Highly automation

3. High cutting efficiency

4. Fast cutting speed

5. Non-contact cutting

6. Variety cutting material

Fiber Laser Cutting Machine Parameters

Fiber Laser Cutting Machine Parameters | Model | GS-LFD3015 |

| Laser source medium | Fiber |

| Laser power | 500W~1500W |

| Cutting range(L*W) | 3000mm × 1500mm |

| Z axle stroke | 100 mm |

| Max cutting speed | 36m/min |

| Max positioning speed | 120m/min |

| Wok platform size/Max height of feeding material | 4250x2500mm/more than 120mm |

| Cooling form | water cooling |

| Laser wavelength | 1070nm |

| Min. cutting gap | ≤0.1mm |

| Positioning accuracy of X, Y and Z axles | ±0.03 mm |

| Repeated positioning accuracy of X, Y and Z axles | ±0.01 mm |

Thickness of cutting material

(according to material) | 0.2-14mm |

| Drive model | Imported servo motor |

| Power requirement | 380V,50/60Hz |

| Working temperature | 5ºC-45ºC |

| Continuous working time | 24 Hours |

| Machine weight | About 6750Kgs |

| Outer dimension | 4270mm x2280mm x 1750mm |

| Total protection level of power supply | IP54 |

Constitution of GS-LFD3015 CNC Laser Cutter IPG Fiber Laser Source

IPG Fiber Laser Source

Main technical data:| Laser source | Fiber laser source 500W/1000W |

| Working medium | Doped fiber mirror |

| Output | 500W/1000W |

| Rated input voltage | 380V±10% |

| Power consumption | <5KW |

| Light beam quality BPP | ≥3.5mm*mrad |

| Max cutting thickness | 12mm carbon steel, 8mm SS, 4mm Aluminum board |

| Min kerf width | 0.1 mm |

| Stability of laser power | ±1% |

| Continuous working time | 24 hours |

| Optical route | Fiber transfer |

Raytools Laser Cutting Head

Laser cutting head of stable performance and convenient operation and maintenance

1 non contact capacitor auto tracking system , Z-axis floats stability, auto adjusts optimal focal distance.

2 Two different focus lenses, adapt to cutting various thickness materials, assure the optimal cutting effect.

3 The laser cutting head can bear 2.0Mpa pressure, high pressure gas path, improve cutting ability for the materials difficult to cut such as stainless steel. Cutting Materials

Cutting Materials

It is used to cut the metal materials, such as stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanize plate, pickled plate, copper plate, aluminum plate, etc.Application Industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchen utensils and appliances, craft gifts, tool processing, decoration, advertising and other manufacturing industries.

Cutting Machine Samples Company Profile

Company Profile

Wuhan Hans Goldensky laser system Co.,Ltd. is subsidiary company of Han's Laser Technology Industry Group Co.,Ltd. (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and provide laser cutting, laser welding, laser cladding/quenching, and high-speed laser perforating equipment and solutions.- Top supplier of high power laser generator and laser complete system in China

- Holding subsidiary of Hans Laser in Shenzhen

- High tech enterprise of Optic Valley under government support, with 20000 Industry Park

- Registered capital 80 million, 125 employees

- Total sales amount of 98 million in 2012, profit of 16 million

- Accumulated assets 150 million, asset-liability ratio 30%, 50% increasing speed in the last three years

Save

Save

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans.

Company has been successively undertaken the national development and reform commission (NDRC) national high-tech industrialization demonstration projects, the top ten key projects in Hubei province, Wuhan city top ten industrial projects of science and technology, and other government science and technology projects, including three products listed as a key project of national torch plan by the national ministry of science and technology. We successively obtains the national innovation fund, the electronic information industry development fund and a number of special fund support of Hubei province and Wuhan city, to be listed as the key innovation enterprise in east lake development zone, the key support leading enterprise in "large-scale laser equipment system integration and the new type laser manufacturing field" in Wuhan's 11th five-year plan.

Most of the products of our company has fully independent intellectual property rights, widely used in steel metallurgy, petroleum, tobacco, automobile, machinery, aerospace, chemical, home appliances and other manufacturing industries. In the future, the company will continue to be based on innovation of new and high technology, using its own technology advantages to contribute to the industrialization development of laser processing complete equipment.