| Prod Model: |

GS-HC03 |

| Laser: |

Rofin-DC030 Laser |

| Output Power Range: |

300-3000W |

| Laser Beam Diameter: |

20-25mm |

| Maximum Welding Depth: |

5mm |

| Water-Cooled Unit: |

Lsjr-500bx Cooling System |

| The Minimum Weld Width: |

1mm |

Product Description

HC03 automatic gear laser welding complete sets of equipment

product description

1.The application of laser welding in automobile manufacturing starts from gear welding of transmission. In the design and manufacture of gearbox of automobile transmission, in order to reduce the quality of gear, reduce the volume and difficulty of processing, and save the raw materials, the developed countries have integrated the whole processed gear set or gear Shaft to split processing, and then the two parts welded together to form a whole.

2.HC03 gear high-power laser welding machine mainly consists of high-power Rofin-DC030 / DC035 lasers, water-cooled units, machine tools, automatic preheater, loading and unloading manipulators, CNC system. The control system can realize the integrated control of the whole system such as machine tool, laser, water-cooling unit and shielding gas unit. The parameter adjustment is convenient, centralized display and strong anti-interference ability. The entire system hardware and software configuration is reasonable, stable and reliable operation, durable, equipment, laser protection to meet the safety requirements of the operator's life safety. The gear laser welding machine for the dual variable gearbox gear, double gear shaft laser welding special equipment.

Performance

| Laser | Rofin-DC030 laser (fiber optic, optional) |

| Output wavelength | 10.6μm |

| Output power range | 300-3000W |

| Power stability | ±2% |

| Laser beam diameter | 20-25mm |

| Beam stability | ≤0.15mrad |

| Water-cooled unit | LSJR-500BX cooling system |

| Rated cooling capacity | 50KW |

| CNC machine tools (X, Y, Z axis) |

| positioning accuracy | ≥±0.02m |

| Repeatability | ≥±0.01mm |

| Four stations automatically feeding turntable | 0.9s / station |

| Processing parameters and requirements |

| Maximum welding depth | 5mm |

| The minimum weld width | 1mm |

| Welding speed | 1.5-3.0m/min |

| Workpiece size range |

| Disk teeth outside diameter | φ40-φ130mm |

| the inside diameter of | φ35-φ70mm |

| thickness | 20-50mm |

| Gear shaft maximum length | 350mm |

| Gear shaft positioning maximum diameter | φ35mm |

| Control System | Siemens 828D + auxiliary PLC |

Features

1.High degree of automation: the use of automatic preheating machine, automatic loading and unloading manipulator, four-station automatic tray, etc.

2.high product quality: the use of automatic pressure welding structure, effectively reducing the welding deformation, improve production efficiency and product quality

3. high equipment integration: the automatic preheating machine, welding host, unloading conveyor belt integrated into one

4. Not affected by the size of the space, welding small or close spacing parts

5.Non-contact welding, can effectively reduce the deformation and wear appliances

6.A wide range of solderable materials, can be of different materials or materials of different properties of two kinds of metal joints

7. Will not be disturbed by the magnetic field, no need to use the electrode, no pollution

Maturity and stability of laser processing

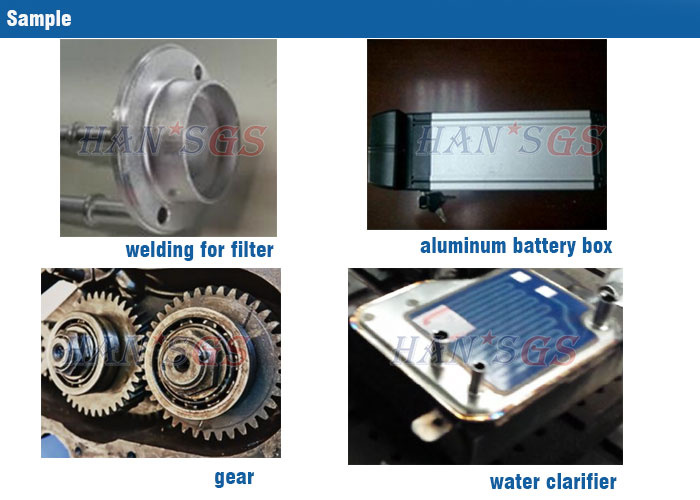

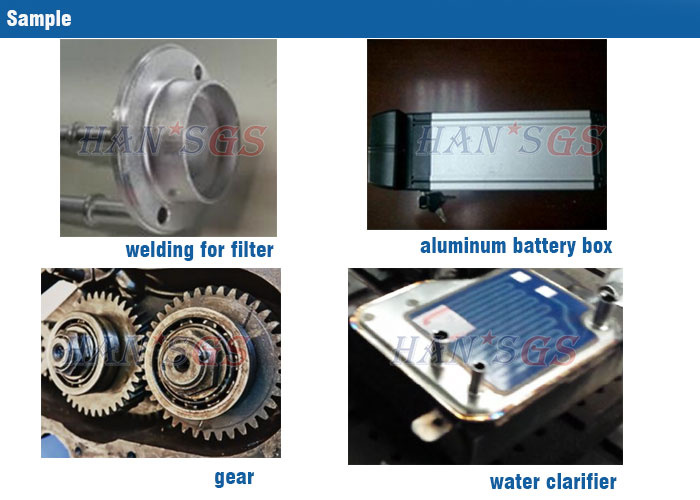

Through years of laser welding applications, the laser industry has accumulated a lot of process data, including gearbox gear welding, saw blade welding, radiator welding, steel galvanized sheet welding, and filter Welding, heat exchanger welding, aluminum alloy battery box welding, space three-dimensional welding, etc., these successful cases show that laser applications for users to create high economic and social benefits.

Sample

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans.

Company has been successively undertaken the national development and reform commission (NDRC) national high-tech industrialization demonstration projects, the top ten key projects in Hubei province, Wuhan city top ten industrial projects of science and technology, and other government science and technology projects, including three products listed as a key project of national torch plan by the national ministry of science and technology. We successively obtains the national innovation fund, the electronic information industry development fund and a number of special fund support of Hubei province and Wuhan city, to be listed as the key innovation enterprise in east lake development zone, the key support leading enterprise in "large-scale laser equipment system integration and the new type laser manufacturing field" in Wuhan's 11th five-year plan.

Most of the products of our company has fully independent intellectual property rights, widely used in steel metallurgy, petroleum, tobacco, automobile, machinery, aerospace, chemical, home appliances and other manufacturing industries. In the future, the company will continue to be based on innovation of new and high technology, using its own technology advantages to contribute to the industrialization development of laser processing complete equipment.