| Prod Model: |

BD550 |

| Color: |

Grey |

| Certification: |

Ce, ISO9001 |

| Application: |

High Frequency Converter Transducer |

| Output Type: |

Triple |

| Principle Of Work: |

Vector Control Transducer |

| Switch Mode: |

PWM Control |

| Main Circuit Type: |

Voltage |

| Brand: |

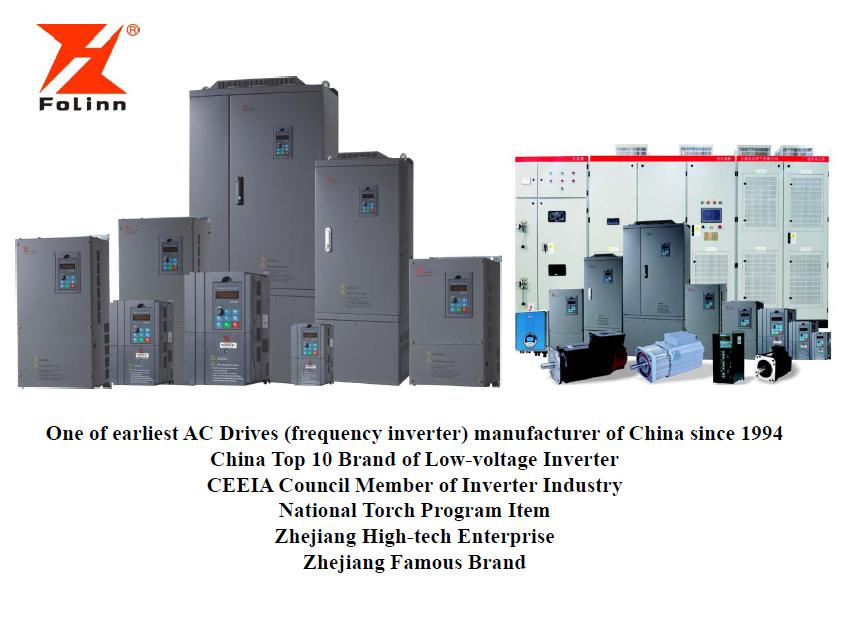

Folinn |

Product Description

BD550 Seris High Functional Vector Inverter

Products Technical Parameters

| ITEM | BD550 SERIES |

| Input voltage | 3AC380V±15% |

| Power range | 380Vlevel:2.2kW~315kW |

| Output frequency range | 47~63Hz,power factor≥95% |

| Control mode | Non-PG vector control and V/F control. 15 choices of V/F curves fixed model, and user-defined V/F curves free setting function |

| Source of operation instruction | given by panel, terminal and RS485 communication |

| Source of given frequency | given by panel figure, analog quantity, RS485 serial communications, multi-speedsimple PLC and PID etc. |

| Overload capacity | type B: 150% rated current 60s,180% rated current10s

type P: 120% rated current 60s,150% rated current 10s |

| Pull-in torque | 0.5Hz/150%(non-PG vector control(SVC)),range of speed 1:100(SVC),control accuracy of speed : ±0.5% (SVC) |

| Carrier frequency | 1.0kHz~15.0kHz,and can be automatically adjusted according to temperature and load characteristic. |

| Frequency resolution | the given digital value is 0.01Hz,and the analog quantity is given as the highest frequency plus 0.1%. |

| Torque elevation | manual torque can elevate 0~30%,and implement control over the set modes of many VC torque. |

| Brake | DC braking when starting and closing down. |

| Internally installed process PID | convenient for the realization of close-loop control of quantity of process (pressure, temperature, rate of flow); |

| Input and output terminal | * 6 multifunctional digital output terminal ;

* 3 analog input and 2 relay output (one of them can be programming, and the other is malfunction output),

* 2 transistor open collector, and 2 multifunctional analog input terminal. |

| Inching operation | * frequency range: 0.0Hz~ maximum frequency of output,

* time of inching acceleration and deceleration: 0~3600.0s |

| | |

LED can display set frequency, output frequency, output voltage, current output and other parameters.

Product overview

The series of BD 550 high-performance inverter adopts the advanced Flux current vector control technology of Anchuan Motor, which is equipped with various kinds of advanced applications such as speed control, torque compensation, slip frequency compensation, energy-saving control, revolving speed tracking and self-learning that can meet the demands of customers of different industries.

Product features

Suitable for high-end situations such as high precision, quick response, high torque, large inertia, and potential load.

Perfect self-learning function, and ultra-low speed high starting torque. It can output 150% rated torque when the speed in closed loop vector control status is 0.

RS-485 communication interface is optional. And it completely support MODBUS communication protocol.

Provided with protection function for many malfunction: overcurrent, overvoltage, undervoltage, overheating, default phase and overload, etc.

Self-learning function: completely solve the unsatisfactory problem of vector control and give full play to the performance of motor.

V/F curve: 15 V/F curves, and user-defined V/F curves are available for users.

DWELL (pause) function: the output frequency keeps constant within certain time during the acceleration and deceleration process, and then proceed the acceleration and deceleration motion again. In cases of load with large inertia, such as before hoisting machinery slings weight, the wirerope of lifting hook is generally in loose status. After presetting acceleration pause function, firstly, tensioning the wirerope before lifting; in cases of low environment temperature, the lubricating oil of some machines are easy to freeze, thus it's required to run with a low speed for a short time, and then accelerate after the lubricating oil dilutes; for those electromagnetic braking motors with mechanical braking equipment, during the loosening process of magnetic brake, it's required to run at a low frequency for the purpose of reducing the friction between braking rubber and braking club. Accelerate after the magnetic brake totally loosens.

Applications

Metal processing, numerical control machine tools, drawbenches and other machineries

Boiler air blowers, induced draft fans, exhaust blowers underground coal mine

Municipal engineering, energy conservation transformation of central air-conditioning

Air compressors, cyclone clusters, air blowers, winchs, belt conveyors

Circulating water pump, make-up pump, water injection pump, fuel delivery pump

Papermaking equipment, chemical industry, pharmaceutical industry, textile industry ,etc.