| Prod Model: |

MTC |

| Heating Power: |

6kw, 9kw, 12kw, 18kw, 24kw, 26kw |

| Flow Rate: |

43L/Min to 330L/Min |

| Heat Transfer Medium: |

Oil |

| Temperature Range: |

60-200 Degree C |

| Precision Of Temperature Control: |

Pid Minus/Plus 1degree C |

| Cooling Mode: |

Inderect Cooling |

| Suit For: |

Injection, Extruder, Blowing Machine |

Product Description

Water type mold temperature controller

Application

This Mold Temperature Controller has been designed to maintain a constant temperature, using water or oil as medium. Mold temperature controller is used to control temperature in various industrial fields, such as: Reaction kettles, extrusion forming equipment, rubber forming machinery, cast film production lines, cable extrusion production lines, the dies for precise plastic molding, the dies for the compression casting of magnesium/aluminum/zinc alloy, roller pressing applied in rubber/plastic and leather industries, crude oil heating of the oil sinks on tankships, paper making industry, bottle blowing, and so on.

Relative to the oil temperature control system, the use of water as the media has its advantages: high heat transfer efficiency, less pollution, easy access to water resources, but the temperature range is small, up to only 98 ºC.

Developed by Hadrdega ultra-boiling water mold temperature controller, the temperature range has reached 120 ºC ~ 180 ºC and temperature control accuracy of ± 0.1 ºC make the use of water type temperature machine with a broader space.

Features

1. Casting shunt, to ensure uniform water

2. Perfect security protection, fault display

3. Explosion-proof equipment for pipelines

4. Microcomputer control board PID ± 1 ºC

5. Automatic air-exhausting function after startup

6. Optional: Air blowing and return water function.

7. Pump power & heating power can be customized

8. CNC main frame thickness 2mm, plate thickness 1.5mm, baking finish

9. Isolated electric box for longer service live, free from high temperature pollution

10. With imported overpressure protection & pressure display to ensure safety of pipelines

11. Heating pipe and pump electrical appliances adopts original Schneider Electric, with air switch

12. With reverse phase / phase shortage / water shortage / overload / over temperature / overpressure alarm function and by-pass pressure relief circuit.

Technical Specifications

Model MTC | 6KW | 9KW | 12KW | 18KW | 24KW | 36KW |

Medium | Clean water |

Operational temperature range | Max. 100ºC |

Heater power | kw | 6 | 9 | 12 | 18 | 24 | 36 |

Pump power (50Hz) | kw | 0.37 | 0.75 | 1.5 | 1.5/2.2 | 2.2/3 | 3/4 |

Max. pump flow (50hz) | L/min | 42 | 56 | 110 | 112/160 | 160/220 | 220/330 |

Max. pump Head (50Hz) | m | 28 | 38 | 48 | 48/58 | 58/65 | 65/72 |

Heating tank No. | 1 | 1 | 1 | 1 | 1 | 1 |

Heating tank capacity | L | 4 | 4 | 6 | 8 | 12 | 18 |

Cooling method | Direct cooling |

Temperature precisioin | ±0.5ºC |

Display precision | ±0.1ºC |

Mould coupling | 3/8" (2x2) | 3/8" (2x2) | 3/8" (4x2) | 1" (1x2) | 1" (1x2) | 1" (1x2) |

Inltet / Outlet | 3/4" 3/4" | 3/4" 3/4" | 1" 1" | 1" 1" | 1" 1" | 1" 1" |

Dimensions | L (mm) | 590 | 590 | 690 | 590 | 690 | 690 |

W (mm) | 295 | 295 | 310 | 590 | 620 | 930 |

H (mm) | 685 | 685 | 750 | 685 | 750 | 750 |

Weight | kg | 42 | 48 | 52 | 96 | 104 | 156 |

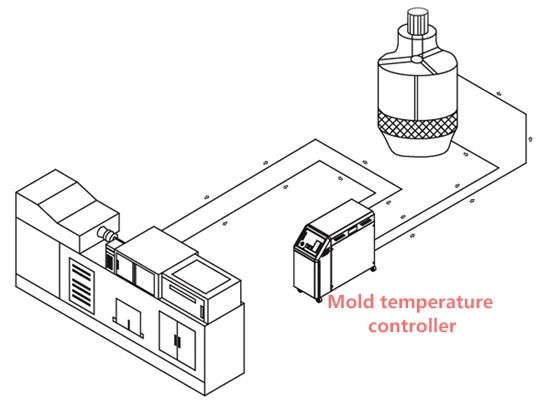

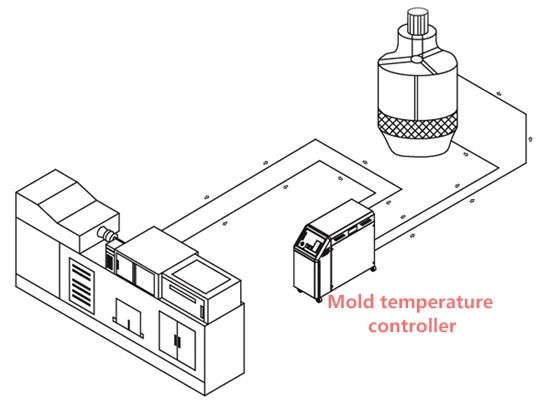

Connection Diagram

Hadrdega has been tirelessly to carry out R&D of plastic auxiliary equipment, adhere to the quakity and service first, to establish long-term and stable partnership on the basis of mutual trust with customers. Established in 2009, Beijing HadrDega Machinery Co., Ltd will focus on providing the most advanced, cost-effective Plastic molding auxiliary systems and services, to help our customers creating higher valueby saving the cost

Hadrdega is a professional manufacturer who specialized in planning the automatic outer system of entire plastic molding. The factory owns very strong R&D capabilities and high-precision equipments, and now has becomed one of the most professional plastic industry auxiliary equipment manufacturer of central feeding system and dehumidification drying system in the word. We have been providing our customers with technical solutions and high quality equipments all those years.

In Beijing and tianjin we have assembly plants and service centers, which can provide customers with quality and the domestic price level in Europe a very cost-effective products, while imported products to solve customer service to worry about! Hadrdega will continue to be your trusted brand partner in China