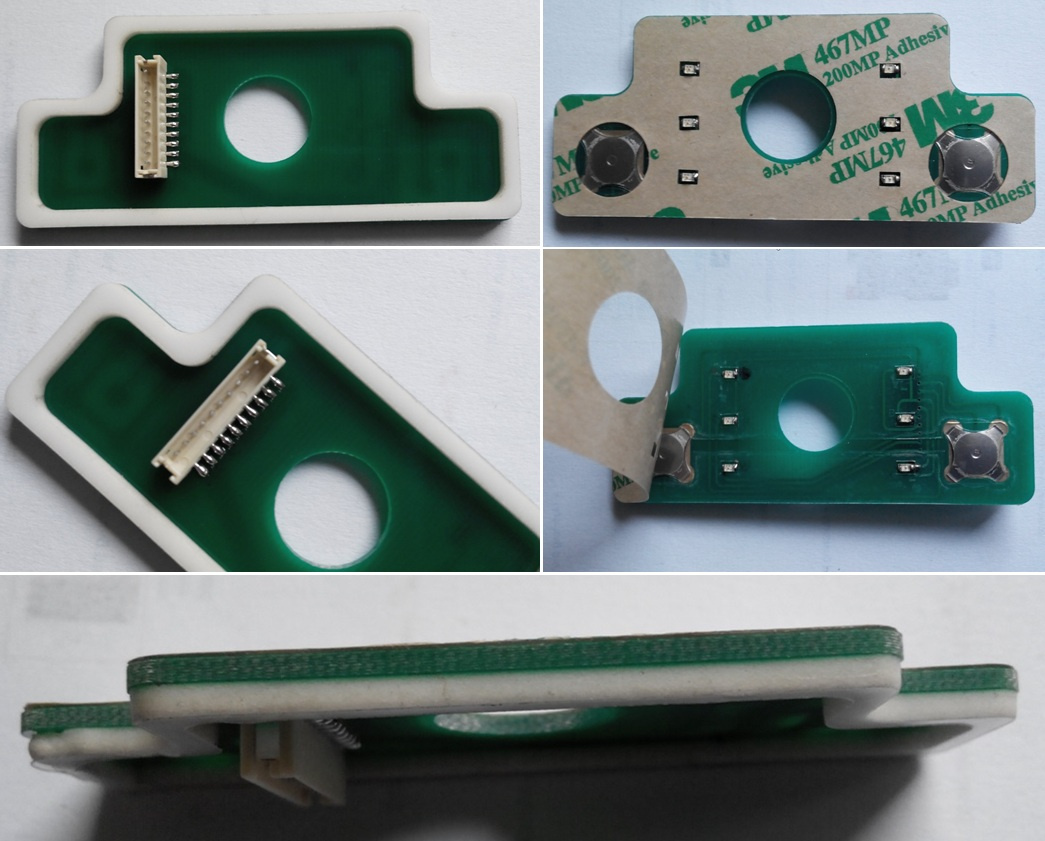

Professional OEM Factory for Small PCB Assembly (MIC0279)

| Price: |

US $ 1.2-2/Piece |

| Trade Terms: |

FOB,CIF,EXW |

| Min Order: |

100/Piece |

| Pay Type: |

L/C,T/T,Paypal,Western Union |

| Prod Model: |

MIC0279 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Metal Domes: |

2 PCS |

| LEDs: |

6 PCS |

| Rear Adhesive: |

3m467MP |

| Connector: |

SMT Chip PCB Latching Connector |

| Other: |

White Circle Foam Rings on Front Side |

| Metal Coating: |

Gold |

| Mode Of Production: |

SMT |

| Layers: |

Double-Layer |

| Base Material: |

FR-4 |

| Certification: |

SGS |

| Customized: |

Customized |

| Condition: |

OEM |

Product Description

LUPHI dedicated to lean manufacturing techniques in all of our operations, including box build assembly and turnkey assembly. We have numerous box build assembly working experiences dedicated to our customers' completed products, ensuring that we continually maximize efficiency and improve our processes through skillful workers and strong engineering capabilities.

We established completed green supply chain which ensure us can get the qualified materials and components of the plastic, metal, cable, rubber, membrane keypad, LCD and other parts very quickly.

> Our PCB Assembly CapabilitiesLUPHI has big capabilities for SMT/SMD assembly (also including Flexible Printed Circuit), through-hole and mixed technology PCB assemblies. BGA down to 0.25mm pitch, 0201 component placements and leadless devices assembly can also be available. We also do the turnkey assembly for our customers. From the product design, drawings making, tool making, electronics components sourcing, plastic, metal, rubber, membrane keypad, wireing harness, LCD, touchscreen etc. sourcing and assembly, final testing, and shipping.

> Manufacturing Equipments for PCB Assembly

3 advanced SMT lines, 2 THT lines, silk screen printer, reflow oven, wave soldering, cleaning system, BGA rework station, AOI, cleaning system.

> Lead-free PCB Assembly(RoHS Compliance)

In light of environmental concerns and customer request, we can offer lead-free PCB assembly which complies with RoHS standards.

> Burning Program and In-Circuit Test (ICT)

We are well sophisticated with decoding and burning program for you. Related test frame will be built to ensure products work effectively according to your requirements.

Our Box Build Assembly Services

1) Global and domestic supply chain for all of your custom manufactured components and materials;

2) Incoming inspection to ensure all components are to specification;

3) Individual component assembly;

4) Sub-assembly testing;

5) Cable assembly;

6) Complete cabinet assembly and testing;

7) Skillful workers and strong engineering capabilities;

8) Many years experiences in the box build assembly industry;

Quantity Requirement | Small prototype orders(less than 500pcs) and mass production orders(above 500pcs) |

Assembly Process | SMT and Thru-hole(THT/PTH) |

Solder | Lead-Free solder |

Components Sourcing | Yes |

Min SMD Component | 0201, 01005 |

BGA | Yes |

VFBGA | Yes |

Double-Sided SMT Assembly | Yes |

Fine Pitch | Yes |

Bare Board Size | 1500mm x 680mm |

Necessary Files | Gerber file |

BOM List |

Test Procedures and other files |

Type of Service | Total assembly, sub-assembly |

Testing | Flying Probe Test |

XRAY Inspection, AOI |

Standard | IPC-A-610 Class III Certified |

Dongguan LuPhi Electronics Technology Co., Ltd. (short for LUPHI bellow) is established in 2008. It located in Ziliang High-Tech Industrial Park, Huaide, Humen of Dongguan. The factory area is about 3500 square meters. It close neighbors to Shenzhen, Guangzhou and Hongkong. To Shenzhen airport is just about 30 minutes and to Guangzhou Baiyun Airport is just about 1 hour. LUPHI is a newly high-tech enterprise for human interface technology and metal, plastic molding, electronics product development, design and assembly.

Our main business and products include designing and manufacturing various kinds of super big size membrane switches, membrane keypads, graphic overlays, membrane circuits, various kinds of backlit membrane keypads like the LED backlit membrane switches, EL backlit membrane switches, LGF backlit membrane switches, the high-tech capacitive membrane switches and nameplates, labels, PCBA, prototype to middle volume metal + plastic + electronics turnkey project assembly.

At the beginning of establishing of LUPHI, we made the factory planning as per the requirements of our customers from USA and Europe, and the international standard. We invested big money to get many new and high accuracy big size semi-auto silk screen printing machines, high-performance pneumatic punching machines, hot embossing machine, high accuracy laser cutting machine, auto die cutting machine etc. LUPHI always regards the quality as our life. We established our inner testing room. We have many high-grade testing machines and equipments in our testing room, like the life testing instruments, 2D measurement instrument, high-low temperature environment test equipment, friction tester, dropping tester, electrical function testing instruments, ink adhesion tester etc. In addition, we also have the high clean room and anti-static clean booth to ensure the product reliability and stability for those high-accuracy and anti-static required products. By such kind of advanced hardware facilities and our experienced quality management team to ensure that each batch delivery to meet our customers' high quality requirements.

We organize the various kinds of training to our employees regularly. For example the product knowledge training, operation and assembly training, quality sense training, fire prevention training etc. To ensure our workers have the skillful operation technique to meet our promise of the on time delivery to our customers from all of the world.

80% customers of LUPHI are from USA, Australia, UK, Germany, Austria, France, Italy, Belgium, Sweden, Russia, Ukraine etc. Countries and areas. We know the overseas customers' requirements and business procedures very well. On this basis, we established our own perfect business development, engineering development & design, artwork making, production and quality control system.

We promise to use high quality raw materials to ensure our products achieve the quality goal of our customers. For example, we use Autotype PET, Lexan PC from GE, Korea Changsung silver paste, ACHESON silver paste, Japan JUJO inks, Nicomatic, CJT connectors, 3M adhesive, Luxking spacers etc.

LUPHI is dedicated to be the standard founder and leader for the membrane switches industry in China!

Warmly welcome you to visit us and discuss business!

More >

Other Products with This Manufacturers