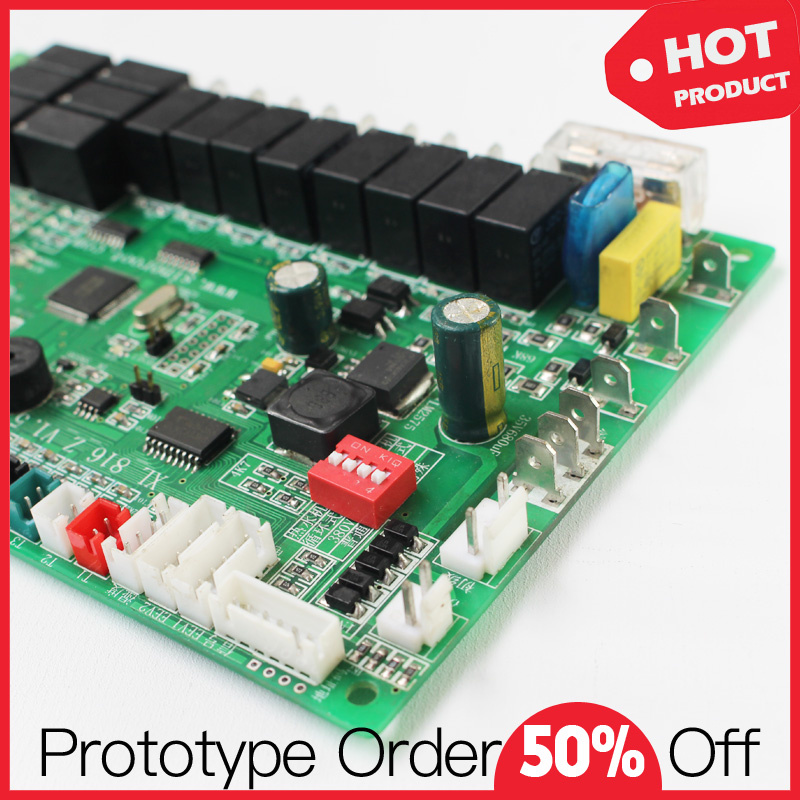

Quick Turn PCB Circuit Board Assembly for LED Electronics

| Price: |

US $ 0.34-0.55/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,Western Union |

| Metal Coating: |

Copper |

| Mode Of Production: |

SMT |

| Layers: |

Multilayer |

| Base Material: |

FR-4 |

| Certification: |

SGS |

| Customized: |

Customized |

| Condition: |

New |

Product Description

Quick Turn PCB Circuit Board Assembly for LED Electronics

Products Description| Layer Count | 1 to 22 layer |

| Material Type | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers.etc. |

| Board Thickness | 0.21mm to 7.0mm |

| Copper Thickness | 0.5 oz to 7.0 oz |

| Min. Line Width&Space | 3/3 mil |

| Min. Mechnical Hole | 0.15mm(0.8mm for Alu PCB) |

| Min.Solder Mask Dam | 0.075mm |

| Max.Aspect Ratio | 10:01 |

| PTH Size Tolerance | +/- 0.05mm |

| Impedance Control Tolerance | +/- 8% |

| Routing Tolerance | +/- 0.1mm |

| Electric Strength | >103KV/mm |

| Current Breakdown | 10A |

| Solder Mask Abrasion | >6H |

| Solder Mask Color | Green/Black/White/Red/Blue/Matt Blue/Matt Black |

| Silkscreen Color | Yellow/Black/White/ Orange/Grey |

| Surface Finishing | HASL / HASL lead free,OSP,

Tin Plating, Silver Plating

Immersion Silver/Tin, ENIG, Hard Gold plating |

| PCB Packing | Inner Packing :Vacuum Packing /Plastic bag

Outer Packing :Standard carton packing |

PCB Circuit Board Assembly Manufacturing CapabilitiesIf bare PCB is bone, PCB circuit board assembly is flesh and blood. PCB manufacture assembly highly determines the total quality of PCBA functions. Our sophisticated engineers excute SOPs and weekly training to ensure the manufacturing processes. Advanced SMT lines can catch up with your demand of high-precision soldering, such as 0201, 0.25mm BGAs, PQFP, PLCC, SOP, SOJ etc. Now we have 6 SMT assembly lines and 4 DIP lines. | Turn Times | Selected Volume | Selected Solder Types |

| Same day through four weeks turns | No minimum order quantity | Leaded |

| Scheduled deliveries | Engineering prototypes | Lead-free/RoHS compliant |

| | Low cost first article builds | No-clean process available |

| Parts Procurement | Selected Stencils | Selected Ball Grid Arrays (BGA) |

| Turnkey | Laser cut stainless steel | As small as .5mm pitch |

| Kitted/Consigned | Nano-coating available | All BGA placements are x-ray inspected |

| Partial Turnkey | | |

| Assembly Types | Selected Component Types | Selected Other Capabilities |

| Surface Mount (SMT) | As small as 0402 package | Pitch components as small as 15 mil |

| Thru-hole | As small as 0201 with design review | Repair/Rework services |

| Mixed Technology (SMT/Thru-hole) | | Mechanical Assembly |

| Single or double sided placement | | Box Build/Electromechanical Assembly |

| | | Sub-assemblies |

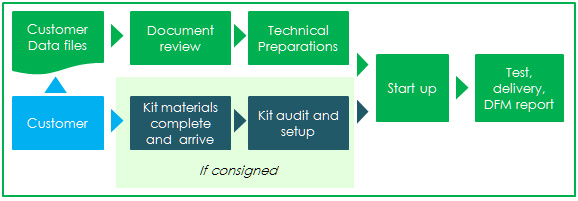

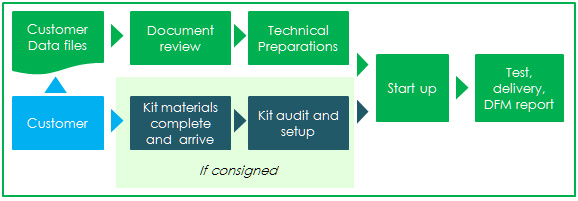

PCB Circuit Board Assembly Manufacturing Process

About UsAs a service-leading PCB manufacturing and PCB assembly (PCBA) partner, NOD Electronics strives to support international small-medium business with 10+ years engineering experience in Electronic Manufacturing Services (EMS). Our headquarter is located in Guangzhou, China. We have 10,000 square meters plant, 287 employees and 42 engineers, monthly capabilities of 15,000 square meters PCB design & fabrication and 80 million spot SMT. We were approved by ISO9001-2008, TS16949, UL, CE, RoHS.Our customers are widely distributed in mainland China, Taiwan, the United States, Japan, Singapore, Korea, Russia, Germany, Switzerland and other parts of the word.

About UsAs a service-leading PCB manufacturing and PCB assembly (PCBA) partner, NOD Electronics strives to support international small-medium business with 10+ years engineering experience in Electronic Manufacturing Services (EMS). Our headquarter is located in Guangzhou, China. We have 10,000 square meters plant, 287 employees and 42 engineers, monthly capabilities of 15,000 square meters PCB design & fabrication and 80 million spot SMT. We were approved by ISO9001-2008, TS16949, UL, CE, RoHS.Our customers are widely distributed in mainland China, Taiwan, the United States, Japan, Singapore, Korea, Russia, Germany, Switzerland and other parts of the word. Your PCB circuit board assembly demand will be perfectly handled by our professional production line and responsible work team.

Your PCB circuit board assembly demand will be perfectly handled by our professional production line and responsible work team.

As a service-leading PCB manufacturing and PCB assembly (PCBA) partner, NOD Electronics strives to support international small-medium business with 10+ years engineering experience in Electronic Manufacturing Services (EMS). Our headquarter is located in Guangzhou, China. We have 10, 000 square meters plant, 287 employees and 42 engineers, monthly capabilities of 15, 000 square meters PCB design & fabrication and 80 million spot SMT. We were approved by ISO9001-2008, TS16949, UL, CE, RoHS.

We strive to be your rightest partner in electronic manufacturing serivce with a commitment from creative team members. Do you agree that every electronic product has its soul, bearing the designer's product concept, just like the Apples and Steve Jobs? Electronic product is a bridge between the customer and designer rather than a cold and ruthless object. Although they have no verbal communication, they have soul connection in between.

So, we perform and create a bridge, which turns your concept or design into a product and present in front of the customers by offering reliable manufacturing solutions and engineering support, including New Product Introduction (NPI), Printed Circuit Board (PCB) design, Printed Circuit Board Assembly (PCBA), Casing (plastic & mental) solutions.

More >

Other Products with This Manufacturers