| Type: |

Rigid Circuit Board |

| Flame Retardant Properties: |

HB |

| Dielectric: |

FR-4 |

| Material: |

Fiberglass Epoxy |

Product Description

You will interest in our schematic design electronic PCBA with high quality

Our Electronic PCBA Manufacturing CapabilitiesIt is a trend that product design company outsources Electronic PCBA manufacturing globally and only focuses on its advantages such as R&D, sales etc. In this way, product design company can push projects and earn the marketplace at very lost cost and with high efficiency, which is huge important for startup programs| Total Pad Size | Standard | Advanced |

| Capture Pad | Drill + 0.008 | Drill + 0.006 |

| Landing Pad | Drill + 0.008 | Drill + 0.006 |

| BC Mechanical Drill (Type III) | 0.008 | 0.006 |

| Laser Drill Size | 0.004-0.010 | 0.0025 |

| Material Thickness | 0.0035 | 0.0025 |

| Stacked Via | Yes | Yes |

| Type I Capabilities single & Double Deep | Yes | Yes |

| Type II Capabilities Buried Vias with Microvias | Yes | Yes |

| Type III Capabilities | Yes | Yes |

| Copper Filled Microvia | Yes | Yes |

| Smallest Copper Filled Microvia | 0.004 | 0.0025 |

| Copper Filled Microvia Aspect Ratio | 0.75:1 | 1:01 |

| Smallest Laser Microvia Hole Size | 0.004 | 0.0025 |

| Laser Via Aspect Ratio (Depth:Diameter) | 0.75:1 | c |

PCB Assembly CapabilitiesIf bare PCB is bone, PCB assembly is flesh and blood. PCB assembly highly determines the total quality of PCBA funtions. Our sophisticated engineers excute SOPs and weekly training to ensure the manufacturing processes. Advanced SMT lines can catch up with your demand of high-precision soldering, such as 0201, 0.25mm BGAs, PQFP, PLCC, SOP, SOJ etc. Now we have 6 SMT assembly lines and 4 DIP lines.| Turn Times | Selected Volume | Selected Solder Types |

| Same day through four weeks turns | No minimum order quantity | Leaded |

| Scheduled deliveries | Engineering prototypes | Lead-free/RoHS compliant |

| | Low cost first article builds | No-clean process available |

| Parts Procurement | Selected Stencils | Selected Ball Grid Arrays (BGA) |

| Turnkey | Laser cut stainless steel | As small as .5mm pitch |

| Kitted/Consigned | Nano-coating available | All BGA placements are x-ray inspected |

| Partial Turnkey | | |

| Assembly Types | Selected Component Types | Selected Other Capabilities |

| Surface Mount (SMT) | As small as 0402 package | Pitch components as small as 15 mil |

| Thru-hole | As small as 0201 with design review | Repair/Rework services |

| Mixed Technology (SMT/Thru-hole) | | Mechanical Assembly |

| Single or double sided placement | | Box Build/Electromechanical Assembly |

| | | Sub-assemblies |

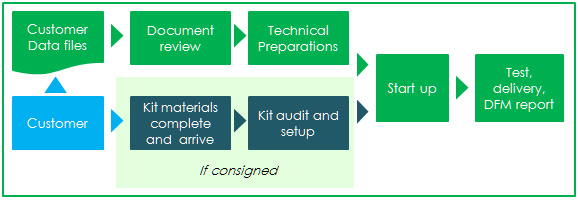

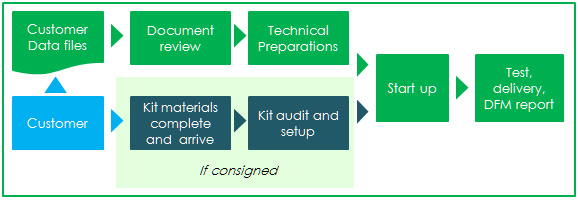

Our Electronic PCBA Process

Our Electronic PCBA Quality Control

Our Electronic PCBA Quality ControlAt upstream stage, we choose branding raw materials including UniOhm, Fenghua, Samsung, Yageo resistor and capacitor, TI, NXP, CJ, Toshiba, Fairchild, ST, Qualcomm, Micron, Infineon IC. Quality and lead time can be ensured due to our good relationship with these brands general agent. In this way, purchase cost and risk would be reduced at some degree

Regarding solder paste, we use famous brands Senju and Loctite. Best solder paste will highly ensure soldering reliability during manufacturing course. Automatic solder paste printing machines make welding spot in uniformity. The 01005 accuracy of high-speed Fuji surface mount machines enable good productivity. Reflow soldering of 10 oven temperatures enables best solution and freezing temperature of solder paste, so to enhance surface mount stability

For the further details, feel free to contact with us

As a service-leading PCB manufacturing and PCB assembly (PCBA) partner, NOD Electronics strives to support international small-medium business with 10+ years engineering experience in Electronic Manufacturing Services (EMS). Our headquarter is located in Guangzhou, China. We have 10, 000 square meters plant, 287 employees and 42 engineers, monthly capabilities of 15, 000 square meters PCB design & fabrication and 80 million spot SMT. We were approved by ISO9001-2008, TS16949, UL, CE, RoHS.

We strive to be your rightest partner in electronic manufacturing serivce with a commitment from creative team members. Do you agree that every electronic product has its soul, bearing the designer's product concept, just like the Apples and Steve Jobs? Electronic product is a bridge between the customer and designer rather than a cold and ruthless object. Although they have no verbal communication, they have soul connection in between.

So, we perform and create a bridge, which turns your concept or design into a product and present in front of the customers by offering reliable manufacturing solutions and engineering support, including New Product Introduction (NPI), Printed Circuit Board (PCB) design, Printed Circuit Board Assembly (PCBA), Casing (plastic & mental) solutions.