| Prod Model: |

TZRS-PVDF175(2X) |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Product: |

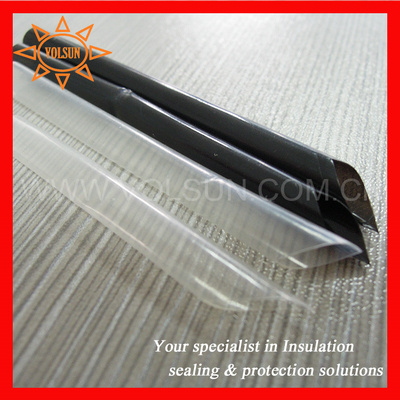

Heat Shrinkable PVDF/Kynar Tube Clear |

| Sample: |

Free for Existing Sample |

| Shrink Ratio: |

2:1 |

| Flammability: |

Vw-1 |

| Environment Certification: |

RoHS |

| Operating Temperature: |

-55degree~175degree |

| Minimum Fully Recovery Temperature: |

175degree |

| Usage: |

as a Jacketing for Components |

| Tensile Strength: |

45MPa |

| Application: |

Electrical Base, Shell |

| Type: |

Insulation Sleeve |

| Maximum Voltage: |

<10KV |

| Material: |

PVDF |

| Thermal Rating: |

150degree |

| Color: |

Clear |

Product Description

Shrink-fit protective heat shrinkable pvdf/kynar tube clear

Description

TZRS-PVDF-(2X) is normally designated as kynar tubing, is a cross-linked, thin-walled, heat-shrinkable tubing offering a high degree of mechanical strength and high-temperature resistance. Fabricated from polyvinylidene fluoride, the tubing has outstanding abrasion resistance and cut-through properties in combination with high dielectric strength. It is inherently flame retardant, semi-rigid and highly resistant to most industrial fuels, chemicals and solvents. When heated in excess of 347°F (175°C), TZRS-PVDF-(2X)-B tubing rapidly shrinks to a skintight fit.

Features

Approval: UL, VW-1, File No.E249362

Meet: RoHS, SAE-AMS-DTL-23053/18

Operating temperature: -55°C to + 175°C

Minimum fully recovery temperature: 175°C

Applications

TZRS-PVDF-(2X)-B tubing is typically used for shrink-fit protection and strain relief of wires, solder joints, terminals and connections. Suggested applications include automotive wiring, jackets, fuse coverings and military wire markers. Because the tubing is transparent, it allows see-through inspection and identification, and is ideal for use as a jacketing for components such as resistors and capacitors. The tubing is readily marked by hot-stamp and print-wheel equipment.

Shrink Ratio

TZRS-PVDF-(2X)-B tubing has a 2:1 shrink ratio. When freely recovered, the tubing will shrink to 50% of its as-supplied internal diameter. The recovered wall thickness is proportional to the degree of recovery. The operating temperature range is from -55°C (-67°F) to 175°C (347°F), with a shrinking temperature minimum of 175°C (347°F).

Technical Performance

| Property | Typical Data | Test Method |

| Tensile strength | ≥45MPa | ASTM D 638 |

| Ultimate elongation | ≥300% | ASTM D 638 |

| Ultimate elongation after aging | ≥200% | 250ºC×168h |

| Flammability | VW-1 | UL 224 |

| Longitudinal expansion rate | -5%~+5% | ASTM D 2671 |

| volume resistivity | ≥1013Ω.cm | ASTM D 876 |

| Cold bending flexible | No tracks | -55ºC×4h |

| Heat shock | No tracks | 300ºC×4h |

| corrosive characteristics | No corrosion | ASTM D 2671 |

Dimensions

| Size | As supplied D(mm) | After full recovered(mm) | Standard package

(M/Roll) |

| Inner diameter d | Wall thickness w |

| Φ0.8 | ≥0.8 | ≤0.4 | 0.25±0.05 | 200 |

| Φ1.0 | ≥1.0 | ≤0.5 | 0.25±0.05 | 200 |

| Φ1.2 | ≥1.2 | ≤0.6 | 0.25±0.05 | 200 |

| Φ1.6 | ≥1.6 | ≤0.8 | 0.25±0.05 | 200 |

| Φ2.4 | ≥2.4 | ≤1.2 | 0.25±0.05 | 200 |

| Φ3.2 | ≥3.2 | ≤1.6 | 0.25±0.05 | 200 |

| Φ4.8 | ≥4.8 | ≤2.4 | 0.25±0.05 | 100 |

| Φ6.4 | ≥6.4 | ≤3.2 | 0.30±0.08 | 100 |

| Φ9.5 | ≥9.5 | ≤4.8 | 0.30±0.08 | 100 |

| Φ12.7 | ≥12.7 | ≤6.4 | 0.30±0.08 | 100 |

| Φ15.0 | ≥15.0 | ≤7.5 | 0.40±0.08 | 100 |

| Φ19.1 | ≥19.1 | ≤9.5 | 0.43±0.08 | 50 |

| Φ25.4 | ≥25.4 | ≤12.7 | 0.48±0.08 | 50 |

| Φ38.1 | ≥38.1 | ≤19.1 | 0.51±0.08 | 50 |

| Φ50.8 | ≥50.8 | ≤25.4 | 0.58±0.08 | 50 |

Volsun Electronics Technology Co., Ltd, founded in 2006, is an innovative company specializing in R&D, manufacture and sale of standard & custom high performance cross-linked materials esp.Heat shrinkable materials for the electronic, electrical, automotive, aerospace, shipbuilding, oil and gas markets in China.

Headquartered in Suzhou, Jiangsu Province, PRC, Volsun has several manufacturing plants equipped with world class manufacturing facilities located in south China and east China to guarantee a sufficient supply to our customers domestically and globally.Supported by our powerful R&D teams and unparalleled rich experience in our products, we thrive on helping our customers make and choose integrated solutions to those challenging problems they face in their fields.

We are specializing in manufacturing different kinds of products, such as PE heat shrinkable tubing, Teflon tubing, Silicone Rubber Tubing, EPDM Tubing, PVC Tubing, Identification Tubing and Finish Cables and Wires etc.

Volsun is more than a supplier of products, it's also a solutions provider.Since its establishment in 2006, with our high performance products, Volsun has been creatively supplying solutions for electrical insulation and mechanical protection for parts, wires, cables and pipes for the electronics, automotive, electrical power, metallurgy, Petrochemical industry markets etc.

Volsun attaches great importance to product quality and consider it the soul of our competitiveness.Most of our products are UL/CSA approved and RoHS compliant.

We will continue to uphold our basic values, I.E.Integrity, Responsibility, Enthusiasm, Innovation, Teamwork, Specialization, Efficiency and Value and struggle for our mission to be a global leader in the industry.