| Prod Model: |

SK-1 |

| Application: |

Audio / Video Players |

| Signal Transmission: |

IR Remote Control |

| Type: |

Button |

| Certification: |

SGS |

| Universal: |

Not Universal |

| Transmission Distance: |

>100m |

| Voltage: |

3V |

| Material: |

Rubber |

| Battery Type: |

Button Battery |

Product Description

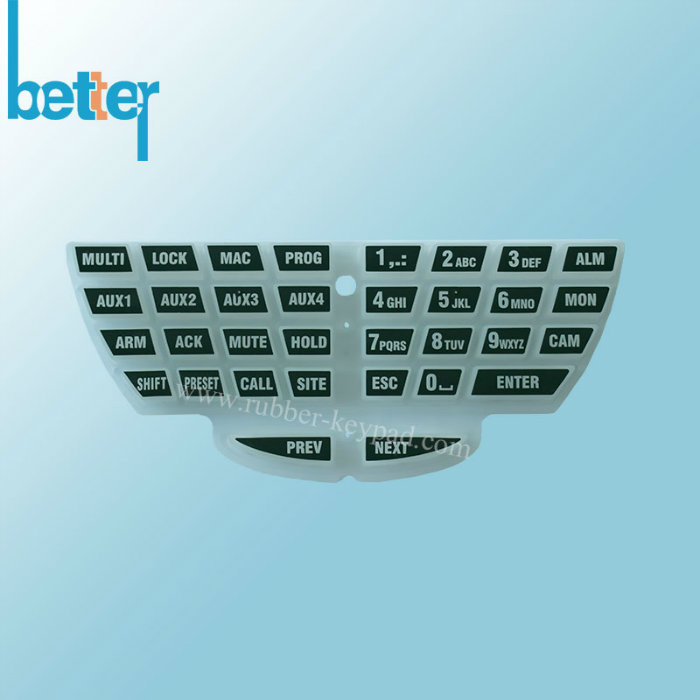

Silicone KeypadSilicone Keypad is also named as Silicone Keyboard, Rubber Button and Rubber Keypad. just as its name implies, Silicone Keyboard is made of translucent elastomer silicone material by compression mold tooling, which is widely used in industrial electronic products, medical products, consumer products as reliable switch performance.

Silicon Keyboard has excellent heat resistance property, cold tolerance, environmental resistance, electric insulation property and fatigue resistance property.

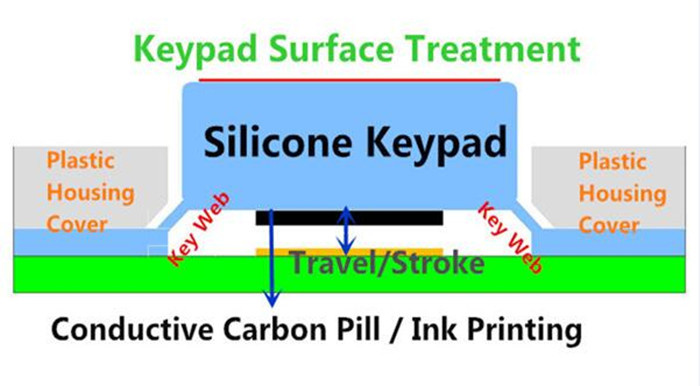

Generally, to a great degree, actuation force determines tactile feel of the silicone keyboard.

Generally, to a great degree, actuation force determines tactile feel of the silicone keyboard.

However, actuation force is not the only factor for good tactile feel. Overall keypad designs, keytop hardness, keypad wall uniformity, keypad travel, and mold tool EDM process are also need taking into consideration.

However, actuation force is not the only factor for good tactile feel. Overall keypad designs, keytop hardness, keypad wall uniformity, keypad travel, and mold tool EDM process are also need taking into consideration.

Silicone Keypad Types

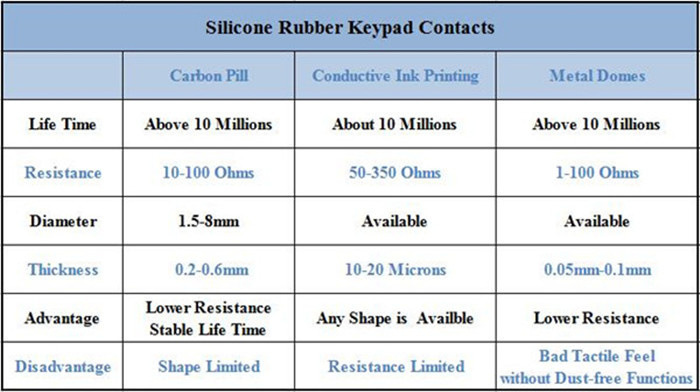

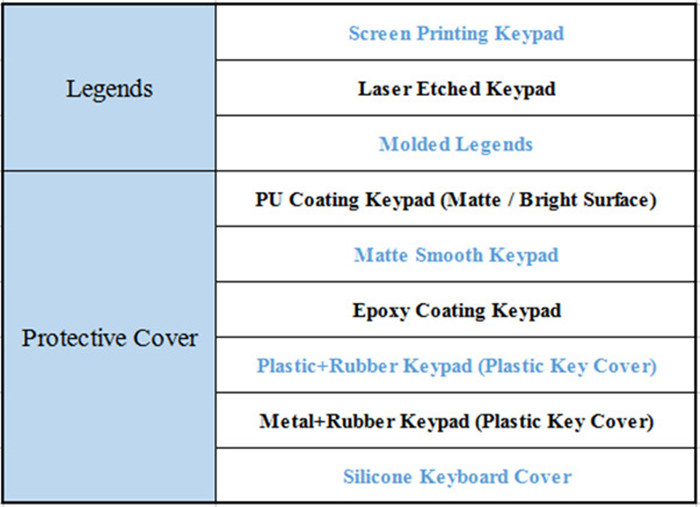

Silicone keypads can be classified by surface legends, conductive ways and material property.

Silk Screen Silicone Keypad

Laser Etched Silicone Keypad

Epoxy Coating Silicone Keypad

P+R Keypad

Double Color Silicone Keypad

Backlight Silicone Keypad

Fluorescent Silicone Keypad

Conductive Printing Silicone Keypad

M+R Keypad

Quick quotation required details

1. 2D, 3D design design drawings in PDF, CAD, STEP, IGS or slprt. format;

2. legend number and colors. If it needs silicone light guide;

3. With or without carbon pills, carbon ink printing

4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc.;

5. Buying quantity.

Our advantages

1. Precision Own Mold-Making Technology since 1998, one stop service for silicone rubber compression molded components, plastic injection molded and liquid silicone rubber molding components.

2. In-depth knowledge of elastomeric materials molded

3. In-depth knowledge of silicone and Liquid silicone tubing mold-making technology and mask molded technology.

4. Mature Experience of avoid out of shape and damage from Production to Shipment: Materials Choice, Design Improvement and Packing Information.

5. Rapid prototyping with full sizes production equipment and production materials.

6. Experienced clean room and precision manufacturing technology.

7. Competitive Price: Original Manufacturer;

1.) Mold-Making Plant

2.) Silicone Rubber Compression Plant

3.) Plastic Injection Plant

4.) Liquid Silicone Rubber Injecton Plant (LSR)

5.) Assembly Plant.

8. Five Experienced Designers and Engineers;

9. Production and Test is in strict conformance with ISO9001; Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

10. Rapid Reaction Organization: Support Customer at short time

Xiamen Better Silicone Import and Export Co., Ltd, which specialized in making Rubber Compression / plastic injection /Liquid Silicone Rubber Injection mold tool and producing silicone rubber compression parts, plastic injection parts, Liquid silicone rubber injection parts: Rubber Sheet, Gasket, O-RING, Seal, Silicone Rubber Valve, Silicone Rubber Keyboard, Rubber Nozzle, Rubber Grommet, Silicone Bushing Sleeves, Rubber Damper, Rubber Bumper, Rubber Bellows, Silicone / Liquid Silicone Mask, Connectors etc.

Xiamen Better Silicone Import and Export Co., Ltd have five production Plant:

1. Mold-Making Plants: Rubber Compression Mold, Plastic Injection Mold, Liquid Silicone Rubber Injection Mold

2. Rubber (Silicone) Compression Plant

3. Plastic Injection Plant

4. Liquid Silicone Injection Plant (Clear Room)

5. Assembly Plants (Clear Room)

As a factory management cooperation, we focus on improving Mold-making technology, each production plant efficiency, and take full advantage to enjoy customer's demands and meet marketing demand.

Our Advantage:

Own Precision Mold-making Technology (since 1998 years)

Experienced Technical Persons and Workers

One-stop Service: Mold Tool Making, Silicone Rubber Compression Production, Plastic Injection Production, Liquid Silicone Injection Production and Assembly.

Experienced Industry Knowledge, Leading industry: Electronic Industry (like Precision Silicone Rubber Smart Cellphone Parts, Rubber Keypad, 3M Adhesive Tape+Silicone Rubber etc), Medical Industry (like Silicone/Liquid silicone rubber mask/valve/gasket etc), Sanitary Industry (like Silicone Shower Head Nozzles).

Well-established and Down-to-earth Company: Improve production technology and also use qualified formal materials