Product Description

Advantages:

1.Our Company Has Great Reputation In Domestic Market.

2.Good Quality Guaranteed With Reasonable Price.

3.OEM,ODM Are Welcomed.

4.Goods Will Be Delivered On Time.

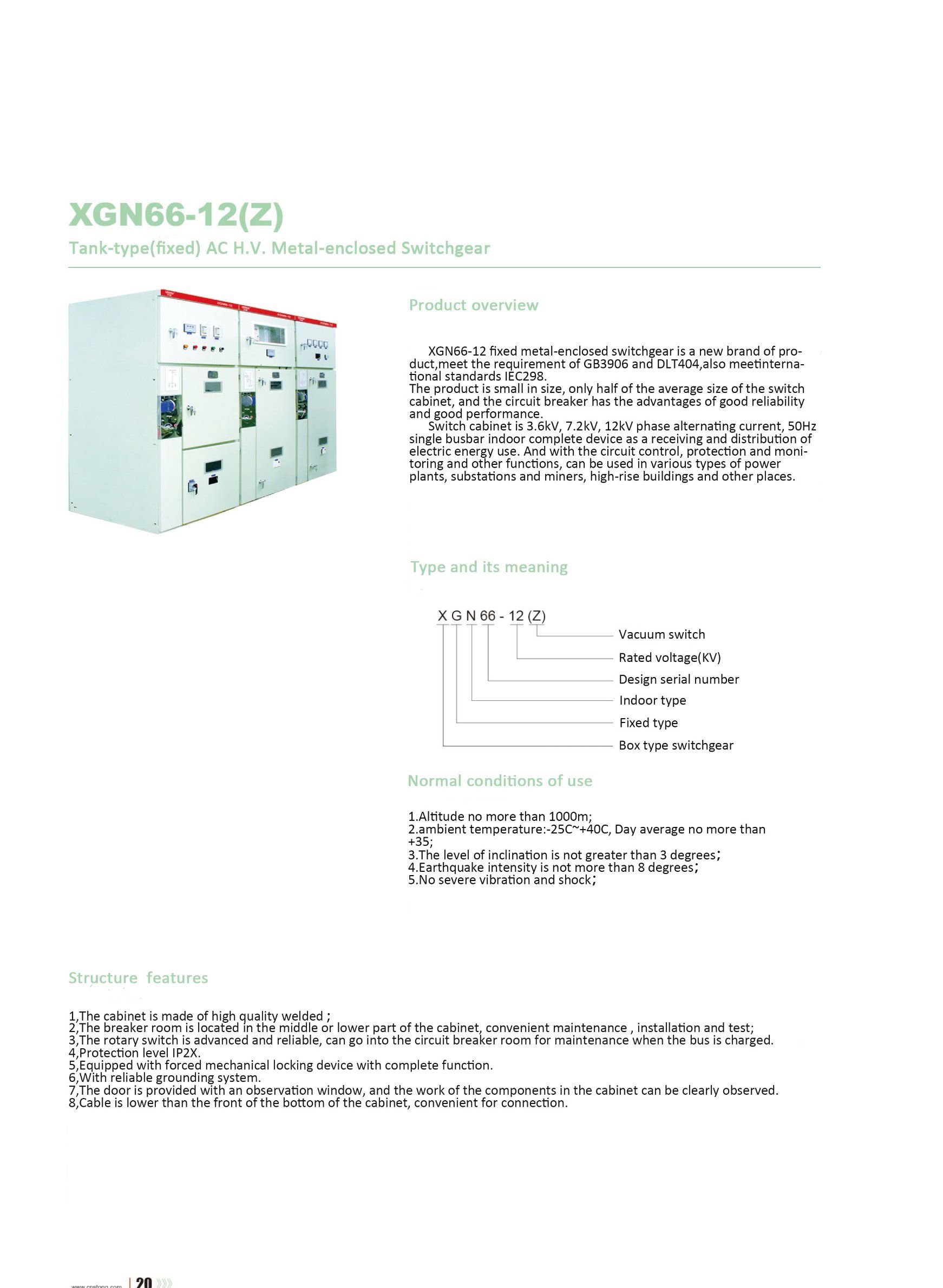

5.Factory Selling DirectlyDescriptions:Tank-type(fixed) AC H.V. Metal-enclosed SwitchgearProduct overview

XGN66-12 fixed metal-enclosed switchgear is a new brand of product,meet the requirement of GB3906 and DLT404,also meetinternational standards IEC298. The product is small in size, only half of the average size of the switch cabinet, and the circuit breaker has the advantages of good reliability and good performance.

Switch cabinet is 3.6kV, 7.2kV, 12kV phase alternating current, 50Hz single busbar indoor complete device as a receiving and distribution of electric energy use. And with the circuit control, protection and monitoring and other functions, can be used in various types of power plants, substations and miners, high-rise buildings and other places.

Type meaning

X-------Box type switchgear

G------Fixed type

N------Indoor type

66-----Design number

12-----Rated voltage

Z-------vacuum switch

Normal conditions of use

1, Altitude no more than 1000m;

2,ambient temperature:-25C~+40C, Day average no more than +35;

3,The level of inclination is not greater than 3 degrees;

4,Earthquake intensity is not more than 8 degrees;

5,No severe vibration and shock;

Structure features

1,The cabinet is made of high quality welded ;

2,The breaker room is located in the middle or lower part of the cabinet, convenient maintenance , installation and test;

3,The rotary switch is advanced and reliable, can go into the circuit breaker room for maintenance when the bus is charged.

4,Protection level IP2X

5,Equipped with forced mechanical locking device with complete function.

6,With reliable grounding system

7,The door is provided with an observation window, and the work of the components in the cabinet can be clearly observed.

8,Cable is lower than the front of the bottom of the cabinet, convenient for connection

XGN66-12(Z)Tank-type(fixed) AC H.V. Metal-enclosed Switchgear

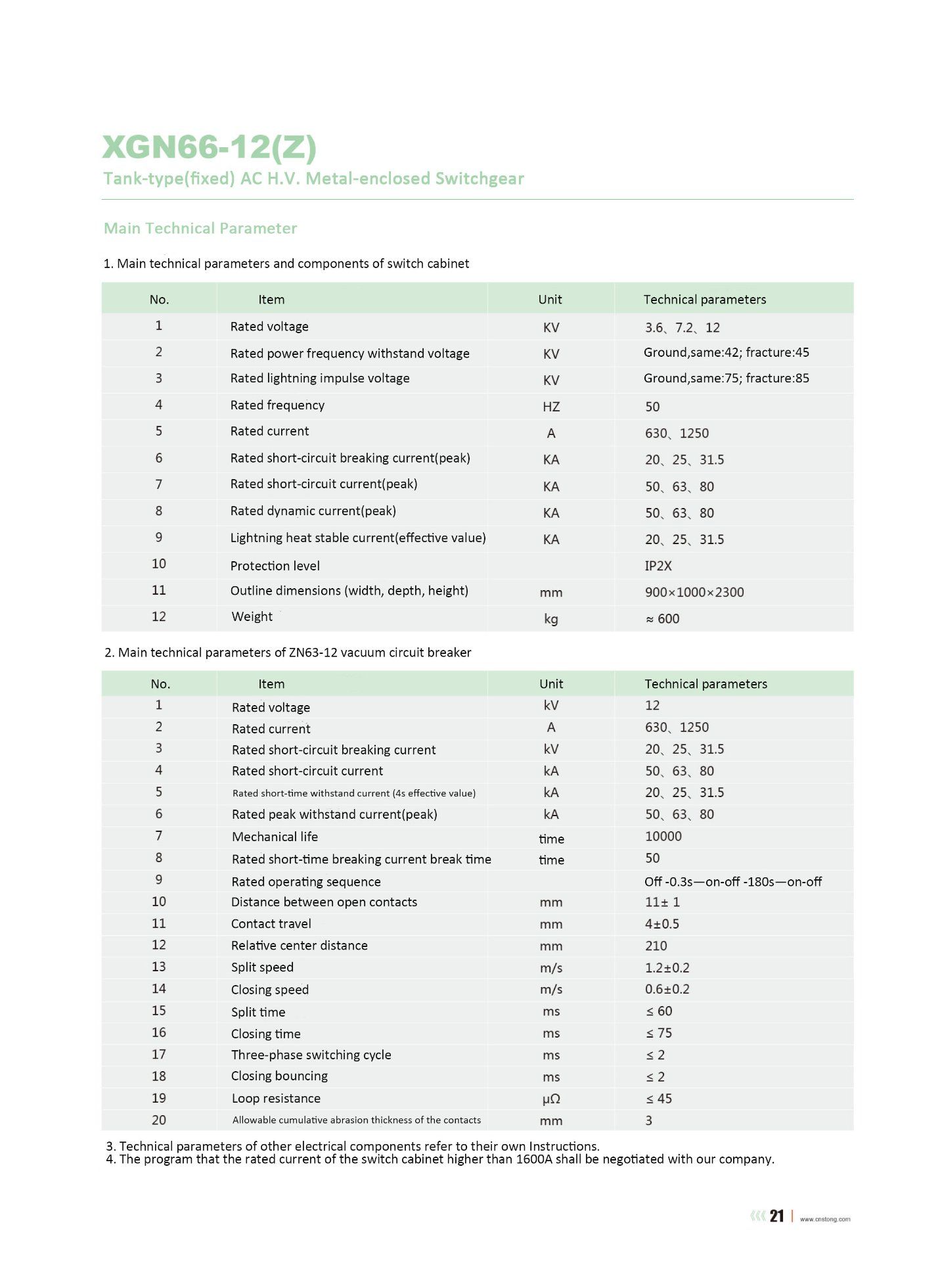

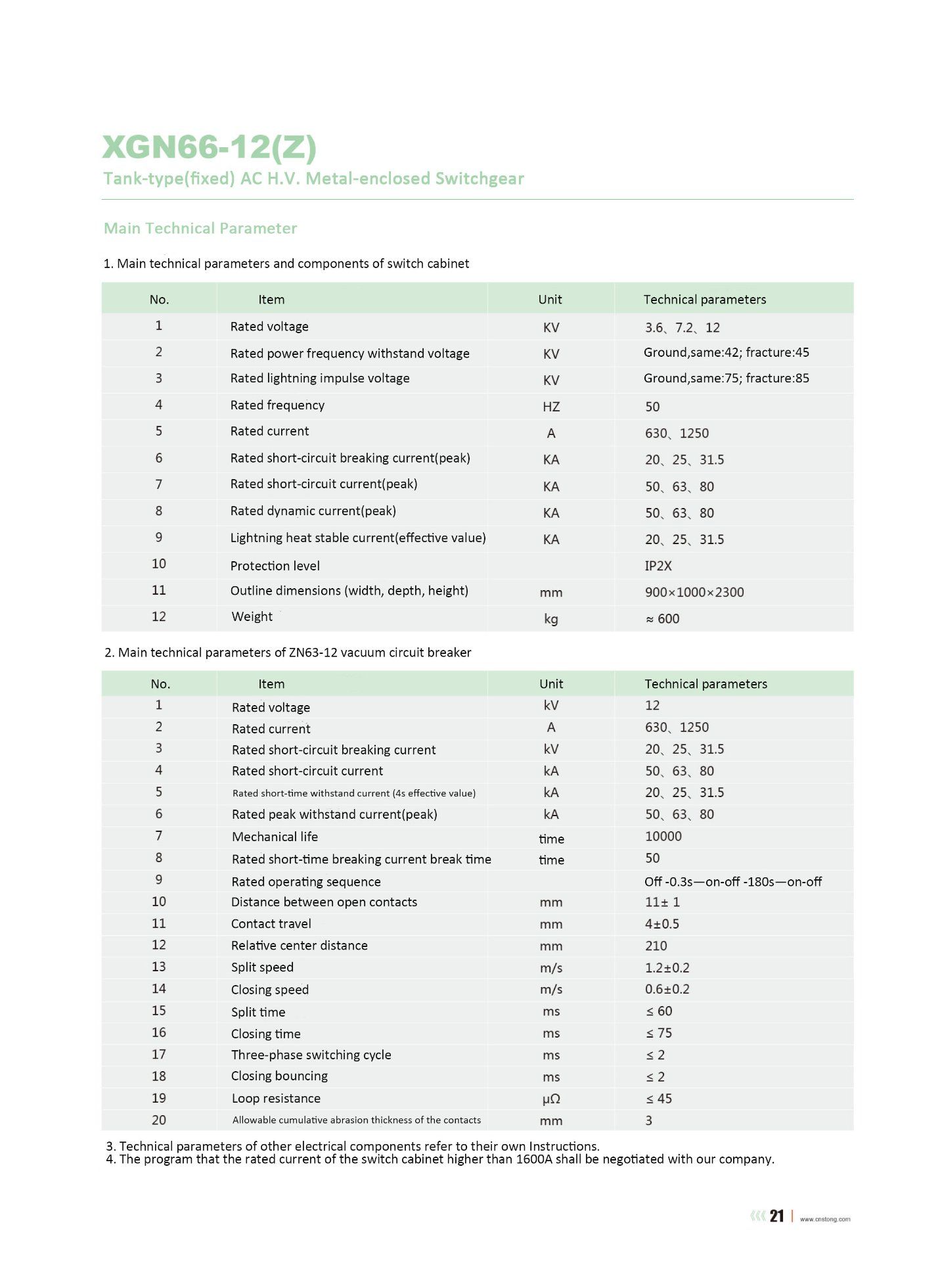

Main Technical Parameter- Main technical parameters and components of switch cabinet

| No. | Item | Unit | Technical parameters |

| 1 | Rated voltage | KV | 3.6,7.2,12 |

| 2 | Rated power frequency withstand voltage | KV | Ground,same:42; fracture:45 |

| 3 | Rated lightning impulse voltage | KV | Ground,same:75; fracture:85 |

| 4 | Rated frequency | HZ | 50 |

| 5 | Rated current | A | 630,1250 |

| 6 | Rated short-circuit breaking current(peak) | KA | 20,25,31.5 |

| 7 | Rated short-circuit current(peak) | KA | 50,63,80 |

| 8 | Rated dynamic current(peak) | KA | 50,63,80 |

| 9 | Lightning heat stable current(effective value) | KA | 20,25,31.5 |

| 10 | Protection level | | IP2X |

| 11 | Outline dimensions (width, depth, height) | mm | 900x1000x2300 |

| 12 | Weight | kg | ≈600 |

- Main technical parameters of ZN63-12 vacuum circuit breaker

| No. | Item | Unit | Technical parameters |

| 1 | Rated voltage | kV | 12 |

| 2 | Rated current | A | 630,1250 |

| 3 | Rated short-circuit breaking current | kA | 20,25,31.5 |

| 4 | Rated short-circuit current | kA | 50,63,80 |

| 5 | Rated short-time withstand current (4s effective value) | kA | 20,25,31.5 |

| 6 | Rated peak withstand current(peak) | kA | 50,63,80 |

| 7 | Mechanical life | time | 10000 |

| 8 | Rated short-time breaking current break time | time | 50 |

| 9 | Rated operating sequence | | Off -0.3s-on-off -180s-on-off |

| 10 | Distance between open contacts | mm | 11±1 |

| 11 | Contact travel | mm | 4±0.5 |

| 12 | Relative center distance | mm | 210 |

| 13 | Split speed | m/s | 1.2±0.2 |

| 14 | Closing speed | m/s | 0.6±0.2 |

| 15 | Split time | ms | ≤60 |

| 16 | Closing time | ms | ≤75 |

| 17 | Three-phase switching cycle | ms | ≤2 |

| 18 | Closing bouncing | ms | ≤2 |

| 19 | Loop resistance | μΩ | ≤45 |

| 20 | Allowable cumulative abrasion thickness of the contacts | mm | 3 |

- Technical parameters of other electrical components refer to their own Instructions.

- The program that the rated current of the switch cabinet higher than 1600A shall be negotiated with our company.

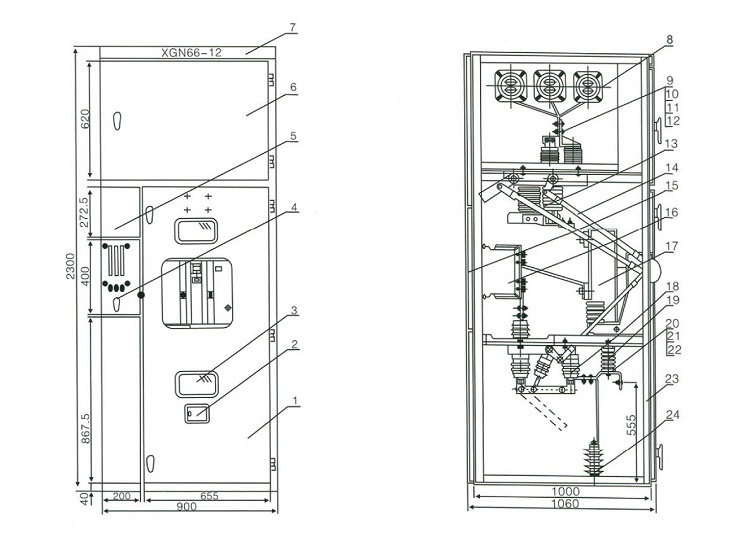

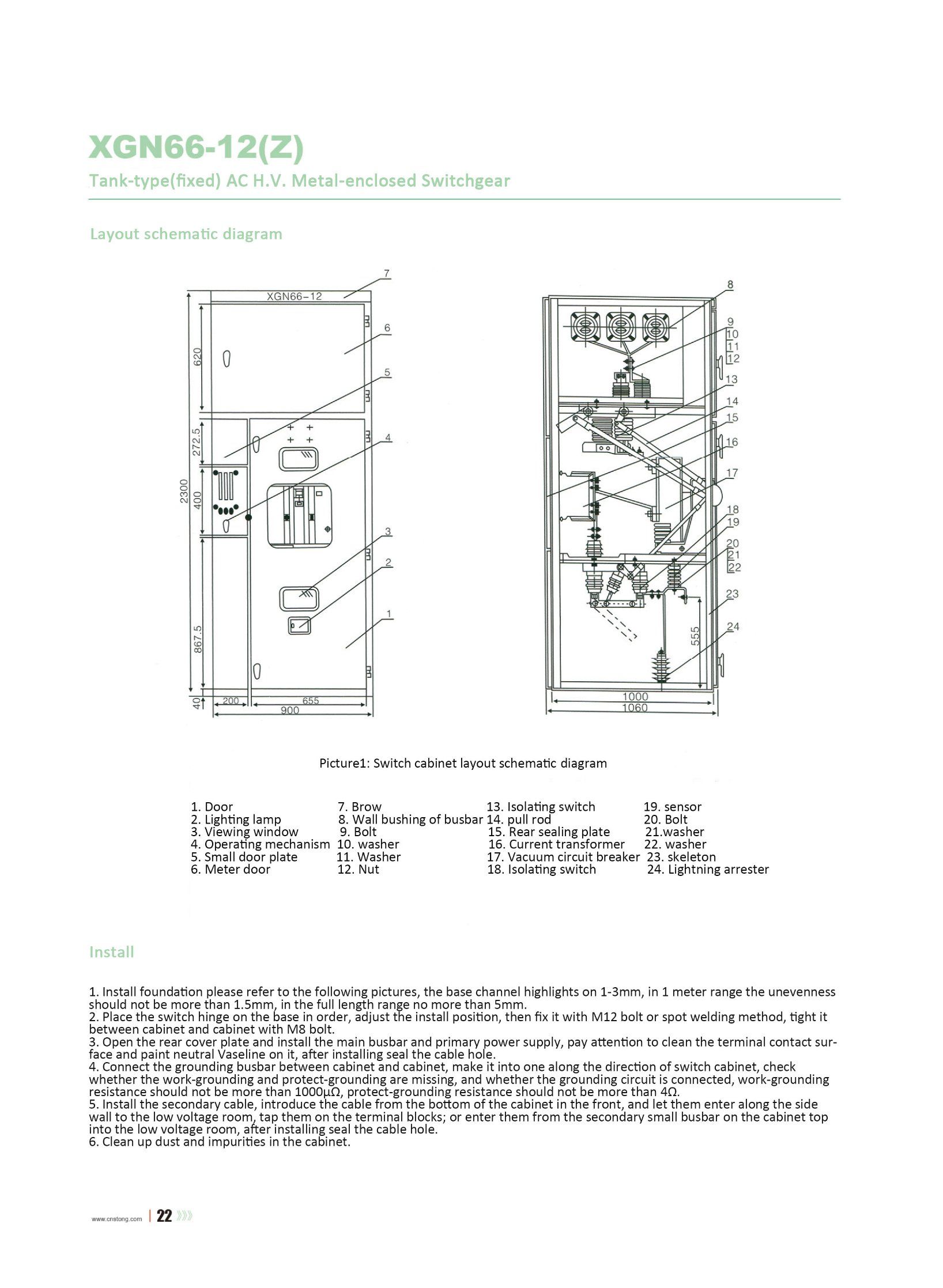

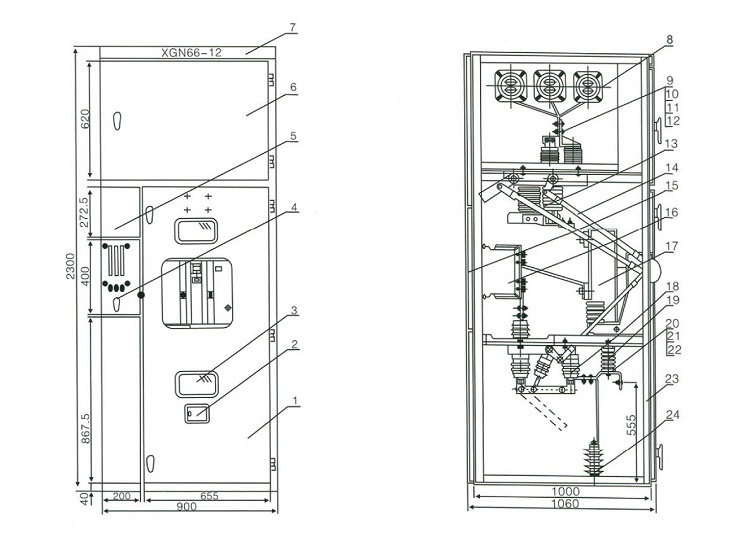

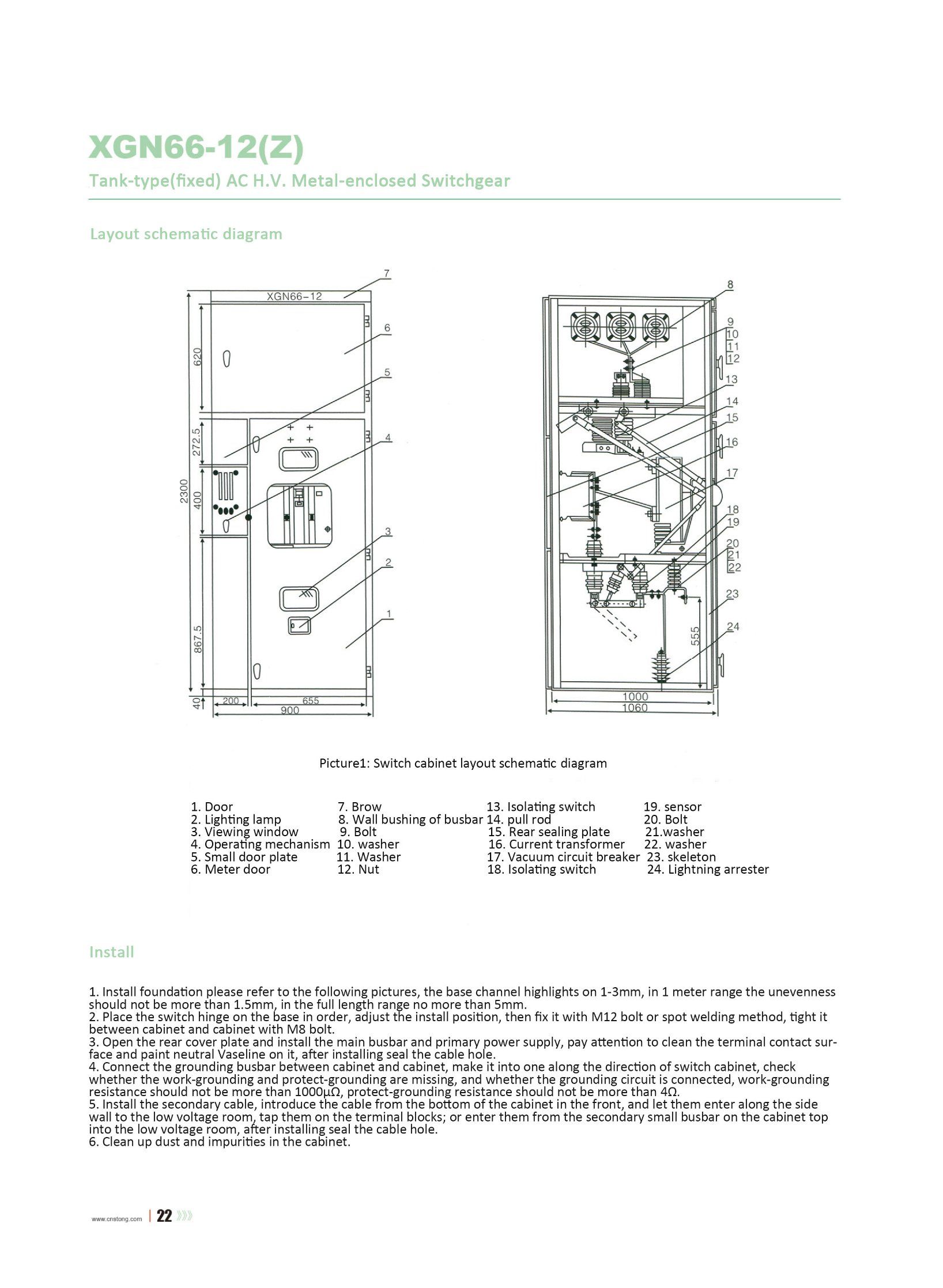

Layout schematic diagram

Switch cabinet layout schematic diagram

1. Door 7. Brow 13. Isolating switch 19. sensor

2. Lighting lamp 8. Wall bushing of busbar 14. pull rod 20. Bolt

3. Viewing window 9. Bolt 15. Rear sealing plate 21.washer

4. Operating mechanism 10. washer 16. Current transformer 22. washer

5. Small door plate 11. Washer 17. Vacuum circuit breaker 23. skeleton

6. Meter door 12. Nut 18. Isolating switch 24. Lightning arrester

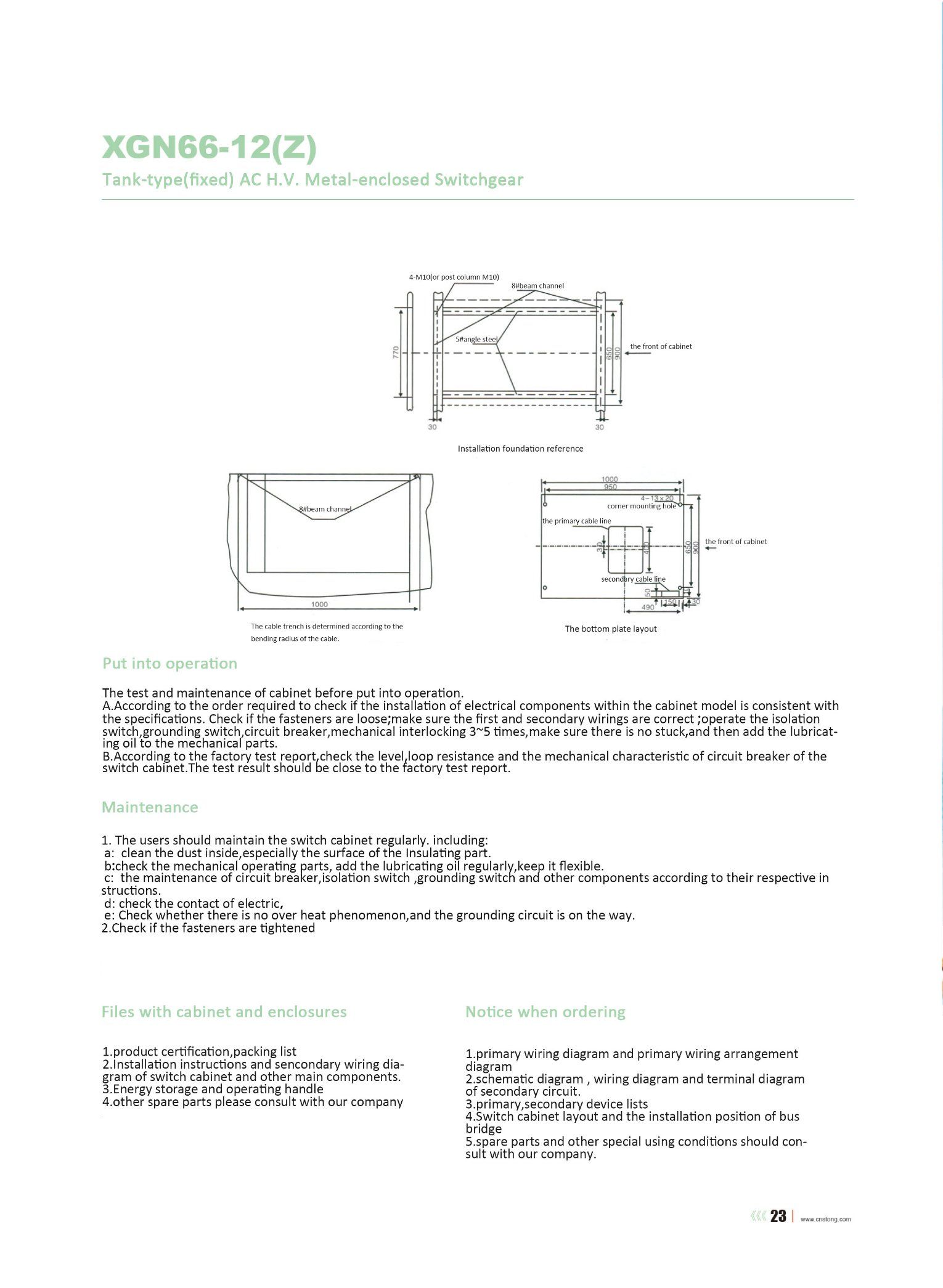

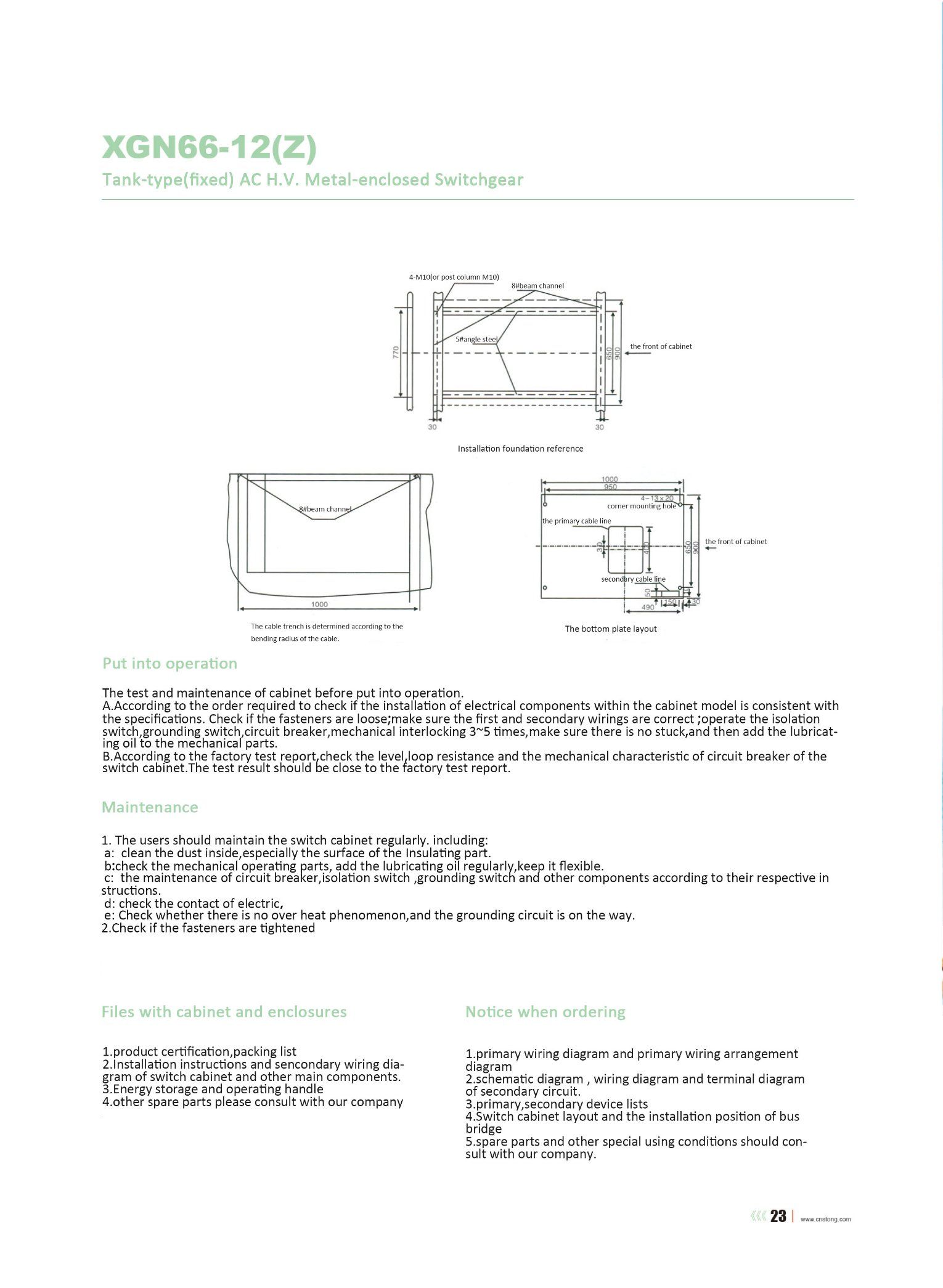

Installation- Install foundation please refer to the following pictures, the base channel highlights on 1-3mm, in 1 meter range the unevenness should not be more than 1.5mm, in the full length range no more than 5mm.

- Place the switch hinge on the base in order, adjust the install position, then fix it with M12 bolt or spot welding method, tight it between cabinet and cabinet with M8 bolt.

- Open the rear cover plate and install the main busbar and primary power supply, pay attention to clean the terminal contact surface and paint neutral Vaseline on it, after installing seal the cable hole.

- Connect the grounding busbar between cabinet and cabinet, make it into one along the direction of switch cabinet, check whether the work-grounding and protect-grounding are missing, and whether the grounding circuit is connected, work-grounding resistance should not be more than 1000μΩ, protect-grounding resistance should not be more than 4Ω.

- Install the secondary cable, introduce the cable from the bottom of the cabinet in the front, and let them enter along the side wall to the low voltage room, tap them on the terminal blocks; or enter them from the secondary small busbar on the cabinet top into the low voltage room, after installing seal the cable hole.

- Clean up dust and impurities in the cabinet.

Installation foundation referencePost columnbeam channelAngle steelthe front of cabinet The cable trench is determined according to thebending radius of the cable. The bottom plate layoutthe first cable linesecondary cable line hole corner mounting holethe front of cabinet Put into operationThe test and maintenance of cabinet before put intooperation.A,According to the order required to check if theinstallation of electrical components within the cabinetmodel is consistent with the specifications.Check if the fasteners are loose;make sure the first and secondary wirings are correct ;operate the isolation switch, grounding switch,circuit breaker,mechanicalinterlocking 3~5 times,make sure there is no stuck,andthen add the lubricating oil to the mechanical parts.B,According to the factory test report,check the level,loop resistance and the mechanical characteristic of circuit breaker of the switch cabinet.The test resultshould be close to the factory test report. Maintenance1. The users should maintain the switch cabinet regularly.including: a: clean the dust inside,especially the surface of theInsulating part.b:check the mechanical operating parts, add thelubricating oil regularly,keep it flexible.c: the maintenance of circuit breaker,isolation switch ,grounding switch and other componentsaccording to their respective instructions.d: check the contact of electric,e: Check whether there is no over heat phenomenon,and the grounding circuit is on the way.f: Check if the fasteners are tightened Random files and enclosures :1,product certification,packing list2,Installation instructions and sencondary wiring diagram of switch cabinet and other main components.3,Energy storage and operating handle4,other spare parts please consult with our company Order notice1,primary wiring diagram and primary wiring arrangement diagram2, schematic diagram , wiring diagram and terminal diagram of secondary circuit.3,primary,secondary device lists4,Switch cabinet layout and the installation position ofbus bridge5,spare parts and other special using conditions should consult with our company.

Packing&Shipping:

Packing&Shipping:

Shentong Technology Co., Ltd. is an integrated professional power equipment manufacturing enterprise of science, industry and trade, which is located in Wenzhou, Zhejiang which is called "The city of electrical"in China. The current enterprise registration funds is one hundred million Yuan. Our company has throughed the ISO9001 international quality certification system. We are also the national power "two network transformation"recommended enterprise. Our company is specialized in the production of HV/LV Integrated Switchgears and switchgears' accessories, power station accessories, such as: Power Transformer, 10kv-40.5kv intelligent vacuum circuit breaker, epoxy resin casting insulators, wall bushing, contact box, earthing switch, load switch, 10kv-35kv current transformer, 10kv-35kv voltage transformer, low voltage current transformers, solenoids, SF6 load switch, high voltage metering box and other electric components. Chinese professional terminal manufacture, Chinese vcb manufacture, electrical manufacture, switchgear manufacture, Chinese CT PT manufacture

Our company has a group of senior technical production staff. The company adopts modern production and management modes. With high quality products and perfect after sale Service, we got good reputation from customers. The products are widely used in aerospace, metallurgy, petrochemical, port, municipal and other industries.

We not only provide customers with excellent quality products, but also strive to use our years of professional experience to provide customers with the best solutions and characteristics of personalized services.

Product Advantages: Well and High Quality Control, Prompt Delivery, New Product, Customer's Design and Logo are Welcome, Competitive Prices, Earth-friendly Products, Small Order Acceptable, ODM Accepted, OEM Accepted,

Packing&Shipping:

Packing&Shipping: