Synchronous Motor 110 240V 3W Air Condition Swing Motor Micro-Wave Oven Motor with OEM ODM

| Price: |

US $ 0.7-7.19/Piece |

| Trade Terms: |

FOB |

| Min Order: |

500/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

| Prod Model: |

Synchronous Motor ty49 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Feature: |

Slow Speed and High Torque |

| Frequency: |

50/60Hz |

| Speed: |

0.8-60rpm |

| No Load Current: |

<=40mA |

| No Load Power: |

<=3.5W |

| Output Torque: |

>=2.5kgf.Cm |

| Insulation Class: |

a Class |

| Application: |

Air Condition Swing Motor Micro-Wave Oven Motor |

| Operating Speed: |

Low Speed |

| Operation Mode: |

Electric Motor |

| Magnetic Structure: |

Inductor Type |

| Structure: |

Rotating Armature Type (',Pole Fixed) |

| Number Of Poles: |

Single-Phase |

| Ventilation: |

Closed |

| Brand: |

OEM/ODM |

| Certification: |

Ce/RoHS/VDE/UL/TUV |

| Function: |

Air Condition Swing Motor |

Product Description

Synchronous Motor 110 240V 3W Air Condition Swing Motor Micro-wave Oven Motor with OEM ODM

Synchronous Motor Introduction:

Synchronous Motor is round motor of two side fixing hole. The rotation speed is 0.8 to 60 RPM, positive rotation, reverse rotation and two-way rotation. It use to the slowly action product of long time and high torque.

Application:

Advertising Lamp Box Household electrical appliances

box fans air-conditioning

a plastic machine

Christmas tree Wheel

automatic controller jewelry toy

Level Gage Oil Pump Home Appliances

Microwave Oven Toaster

Electric Fan, Stove

Advertising Board Stage Light

Spotlight Electric Rotating Light Box

Electric Advertising Lamp Advertising Night Lamp

Turn Signal Light

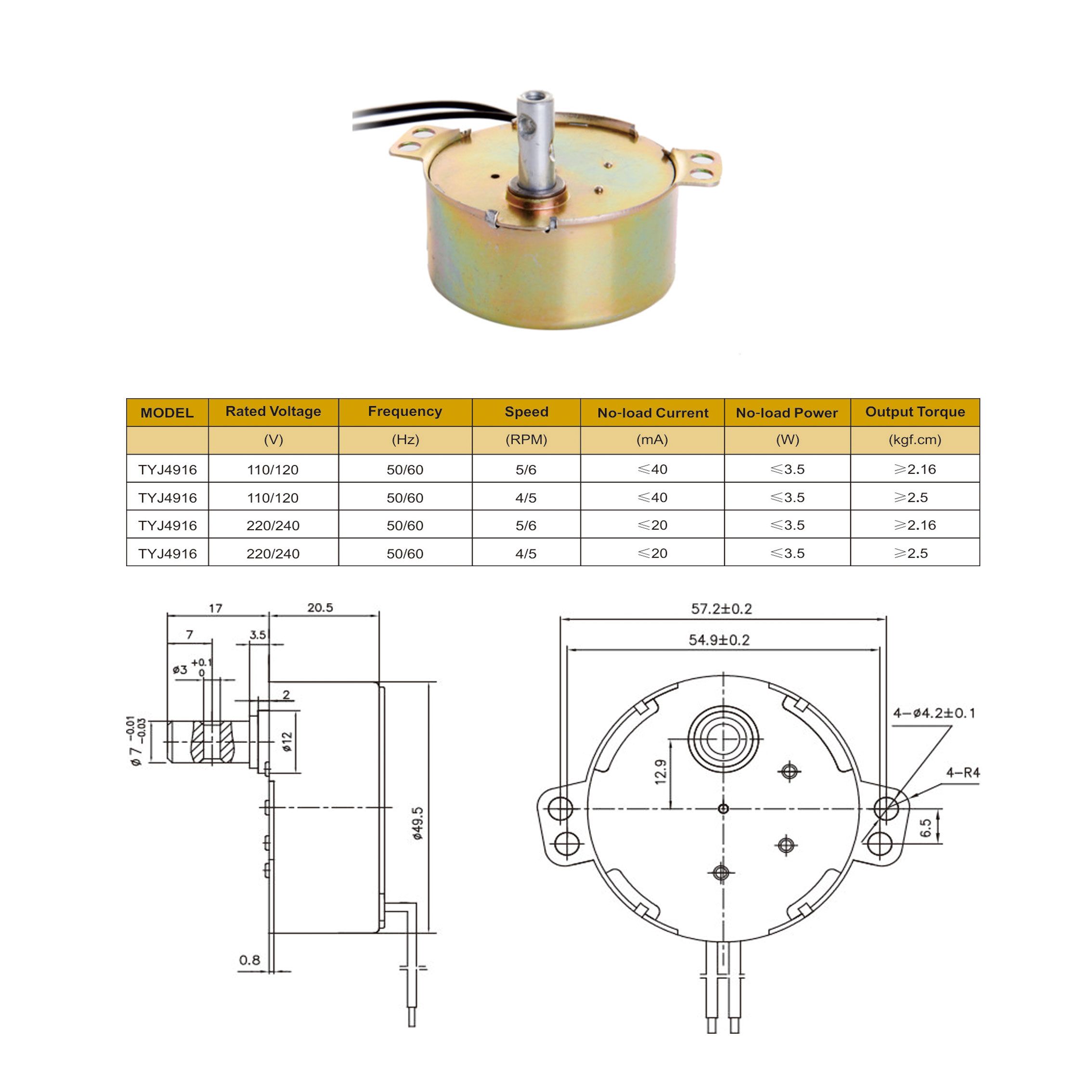

Synchronous Motor Specifications:

• Rated Voltage: 12, 24, 100, 110 ~ 120, 200 ~ 240VAC

• Power Frequency: 50/60Hz

• Input Power: 4 W

• Number of Poles: 12 P

• Rotor Speed: 500 ~ 600 RPM

• Spindle Speed: 0.8~ 72 RPM

• Start Torque: 500 gm-cm ~ 20Kg-cm

(5Kg-cm at 5RPM)

• Spindle Rotation Direction: CW, CCW, Free.

• Operating Temperature: -10 ºC ~ 60ºC

• Insulation Strength: AC 1500V - 1 Min

• Insulation Class: A, B Class

• Lead Wiring: 1007 / 1015 X AWG # 22 X 200 mm

Synchronous Motor Characteristics:

• The U.S regulation-UL quality certification, the EU regulation-CE Marking and RoHS,EMC quality certification.

• Gear group for the senior steel teeth, the copper teeth and steel teeth.

• Copper gear is made by Swiss precision hobbing.

• The motor shell is made by galvanized steel sheet (SECC).

• Low-noise, temperature rise low and insulation high temperature.

• High-torque, long locked, motor not burned.

Synchronous Motor Exterior Material:

steel plate: from JapanMitsubishi ,zincification;gear:metallic copper/steel plate (switch gear:steel plate from Japan Sumitomo/fibre glass of plastics/DuPont plastics),magnet material:magnet powder

Synchronous Motor Ordering information:

Minimum order:10000pcs

Basic Package: 100 / CTN

Basic Carton Size: 370 x 370 x 200 mm / 300 X 590 X 135mm

Weight (NW / GW): 12.5 Kgs / 13.5Kgs

Other information:

•certificates, awards and process.

•Sample: standard motor size such as picture, the unique requirements, Please provide the necessary axis, bearings, rotation speed, rotation, torque and uses.

•Also provide special rotation speed and high-strength torque, please contact our business department.

•The bearing has three kinds of size, and has special bronze bearing, roller bearings, and so on.

Synchronous Motor Main Features: 1)Small size

2) High torque

3) Low speed

4) Long lifetime

5)Wide range of applications

Synchronous Motor Pictures:

ABOUT US:

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world. We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments. As a realiable quality

guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Ritscher group was established in 2006. We always focus on micro-motors for household and industrial electrical appliance. Currently, we have professional micro-motor factories separatlly located in Guangdong & Zhejiang province. It has 50, 000 square meters plants and more than 500 employees, annual output is 5 million PCS and has 10 million PCS annual producing capacity. After years development, we built a great reputation in the domestic and oversea market and have the trust from our global customers.

We started our business from shaded pole motors, after 10 years development, our products is enlarged to BLDC motors, capacitor motors, synchronous motors, stepping motors, servo motors, and PMDC motors. Our products are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators, ovens, air filter, massage machines and many other equipments.

To design the latest technology motors and meet our customers requirments, we have the very capable R&D team, to ensure our products quality, we have very strict manage system for our production department & QC department, to make our cost lower, we have the very professional purchase department, We dedicate to make every details better than we could do.

To offer quick and better service to our customers in Australia and New Zeland, we set up branch office in Australia since 2017 with exprienced consultant to support the business, which will bring more customers to get know of us.

We will keep doing our job, move forward step by step to make our business area wider and brighter.

More >

Other Products with This Manufacturers