| Prod Model: |

CMD |

| Max Rated Current: |

1000A 2400A |

| Connection Method: |

Y,D |

| Rated Voltage: |

4kv |

| Type: |

High-voltage |

| Structure: |

Single-column Disconnector |

| Installation: |

Indoor High-voltage |

| Operation: |

Manual |

| Grounding: |

Single Ground |

| Series: |

Single-Stage |

| Run: |

Vertical Rotation |

| Switching Mode: |

Single Throw-in |

| Certification: |

CE |

| Common Model: |

Cmd |

| Brand: |

Ville |

Product Description

Transformer switch Oil-Immersed on-Load Tap Changer

GeneralCMD On Load Tap Changer is developed as a high quality and high-tech product through several

years of technical creativity and experience of Huaming Group. Since it keeps part of structure that

operated and validated for many years and combines with Huaming's creativity in structure design,

CMD OLTC improves the reliability of long-term usage.

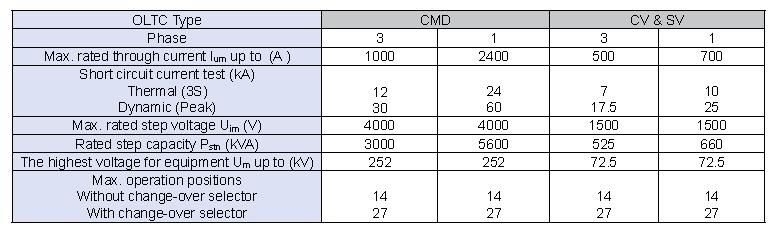

The Highest Equipment Voltage of CMD On Load Tap Changer (OLTC) is 252KV. Three-phase

CMD OLTC is applicable for transformers with highest equipment voltage up to 750KV or less with

neutral point regulation. Single phase CMD OLTC is applicable for middle point regulation, etc. The

maximum rated through current of three-phase CMD can reach 1000A. 2400A is for single phase.

Frequency is 50Hz. By changing the taps under load it is for the purpose of voltage regulation. The

maximum operating position of CMD OLTC is 35 (with change-over selector).

CMD OLTC is a combined type OLTC, which consists of 2 main portions: diverter switch and tap

selector.

CMD OLTC will be mounted to the transformer tank cover by its tap changer head flange,

which serves also for connection to the motor drive SHM-1 through reducer and bevel gear box

(attachment) for the purpose of electrical and remote electrical operation.

This operation instruction includes all the necessary information for the installation and operation of

CMD OLTC. If the structure has some changes, it will not inform separately.

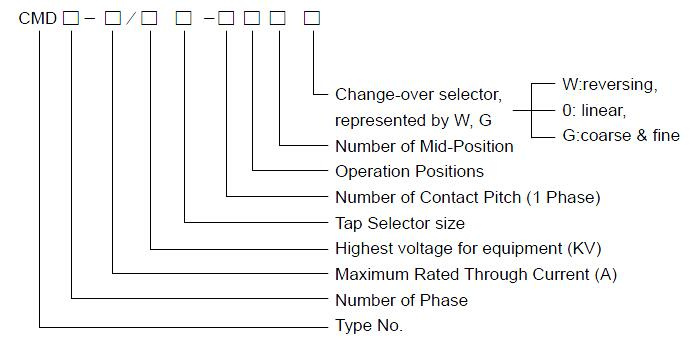

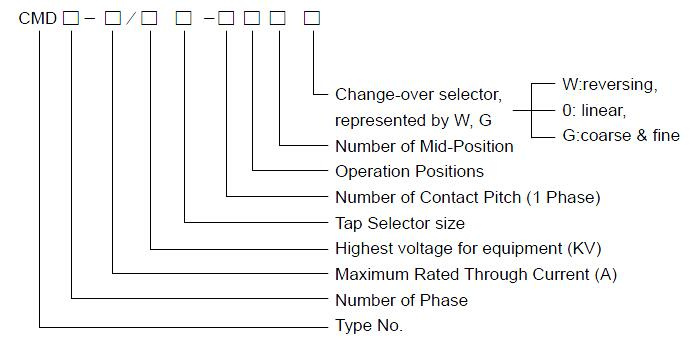

Type designation The operating condition of OLTC

The operating condition of OLTCa. The temperature of oil in which the tap changer operates is - 25ºC ~ 100ºC .

b. The ambient temperature under which the tap changer operates is - 25ºC ~ 65ºC .

c. The vertical inclination level of the OLTC on the transformer towards ground level should not

exceed 2%.

d. The operation site should be free from serious dust and other explosive and corrosive gases.

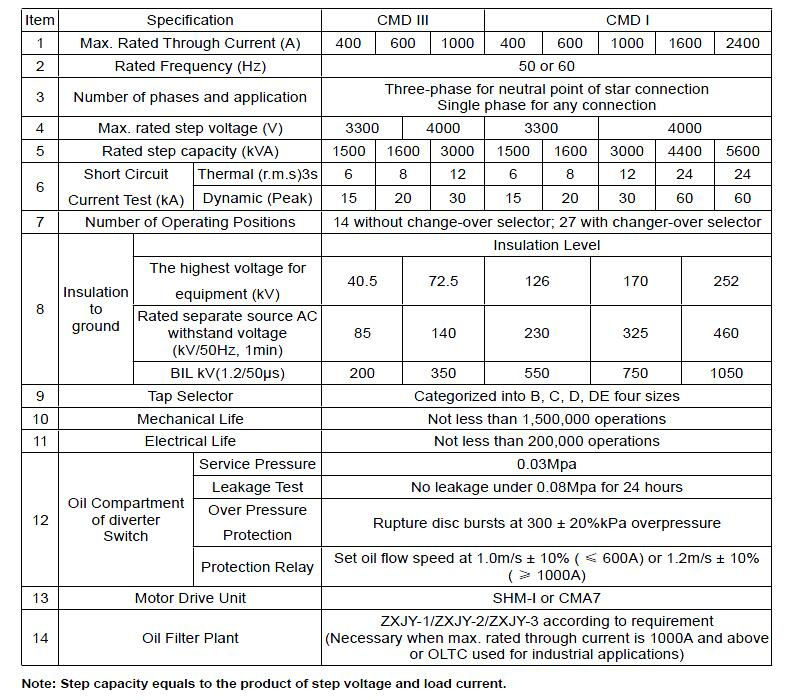

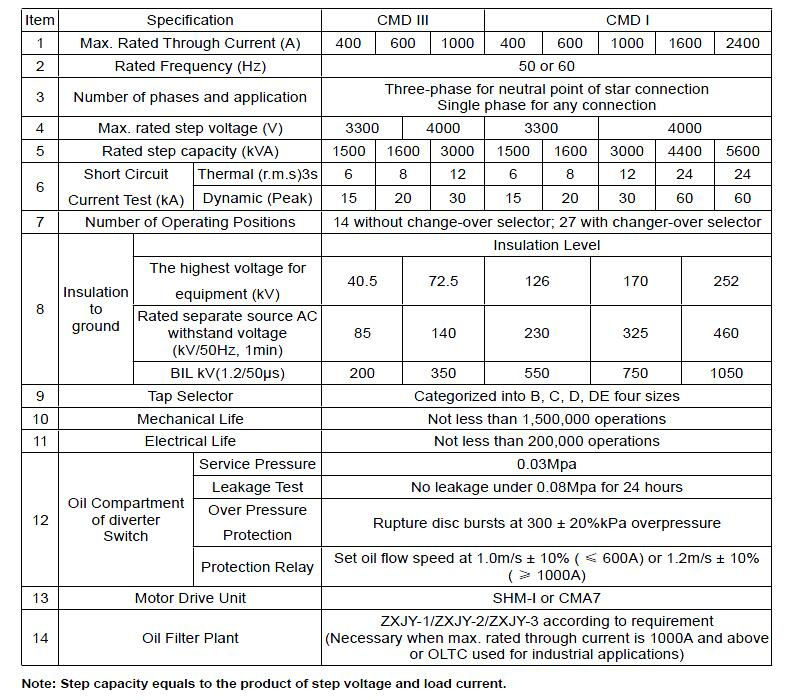

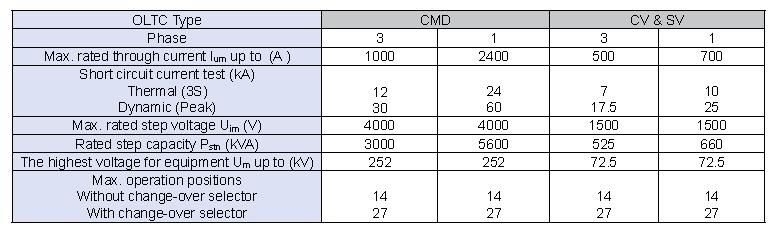

Technical data of Type CMD On Load Tap Changer

Mechanical operation principle of the tap changerThe operation of tap changing begins with the electric motor of the motor drive unit. The driving

force is transmitted to the bevel gear box through vertical driving shaft, and then transmitted to

reducer on the top cover of the tap changer through horizontal driving shaft. The output shaft of

this mechanism drives the insulation shaft. Through turning of the main insulation shaft, it drives

the operation of main driving system of tap changer. One is transmitted to the energy storage

mechanism of the diverter switch (then the energy released by the energy storage mechanism will

drive the diverter switch operation). The other is transmitted to Geneva wheel mechanism of tap

selector. The rotation of Geneva wheel makes the odd and even moving contact of tap selector to

change the operating position.

COMPANY PROFILE:

Main product line: Tap changer and HV switchgear

Tap changer manufacturing with fullest vertical integration

Tap Changer Products Range On-Load Tap Changer

:* Conventional OLTC for transformer with voltage up to 765kV

*Vacuum OLTC for oil transformer with voltage up to 765kV

*Vacuum OLTC for dry transformer with voltage of 72.5kV

Off-Circuit Tap Changer

* Application for the transformer with voltage up to 765kV

Ningbo Ville Electric Co., Ltd. One of wholly owned subsidiaries of VILLE INDUSTRY, It was invested by VILLE INDUSTRY, It is a well-know listed company in China specialized in R&D of electric power technology, equipment manufacturing and engineering services specialized in research, development, production of transformer and high voltage & low voltage electrical power equipment

Our Transmission and distribution companies can provide with whole solution for transformer substation and switch substation trunkey project!

The rated voltage from 11kV up to 132kV.

It locates in Hi-technical enterprise R & D center zone of Ningbo, Zhejiang province, which is one of the well-know coastal city in China. Its professional engaged in power substation, power plant project and electrical power complete equipments.

Working field: Manufacturing, engineering, designing, executing and commissioning for HV and LV electrical products. Turnkey substation from 11KV to 132KV.

Our transformer factory main working is visiting end user's site do measure and reseach before designe, and providing economic transformer solution for customer. Engineering, manufacturing, executing, commissioning and repairing for different kind of transformer (04kv -500kv ).

The products are mainly used in Steel plant; Power - Fossil fuel plant, Nuclear power plant, Railway, Subway and Airport. Wind power generation; Hydroelectric plant engineering; International power generation plant; Power substation transmission and distribution; Residential housing estate power distribution system and so on.

Transformer factory Product includes:

Three phase double (three)- winding power transformer, generator power transformer, auto power transformer, rectifier transformer for each industry, furnace transformer, movable transformer, traction transformer and reactor, power plant auxiliary and standby transformers, transformers for substations of backbone and distribution networks. Transformer for metallurgical companies etc.

In order to achieve the enterprise's strategic target---being stronger, larger, and superior, we continue to expand throughout the world's markets for power transmission and distribution area. And we also actively attach our team to competition, walking forward to the mission of "First-class worldwide transformer supplier"

Supply the guide drawings and installation manuals information directions on the method of handling, storage, mounting and erection of transformers.

Power equipment application:

Power-fossil fuel plant, Steel plant, Infrastructure- railway, international generation, substation, hydropower station, wind power substation, transmission and distribution.

We has excellent experience and good capacity in complete projects equipments in Generation, Substation, Transmission and Distribution from 400V-330kv, especially in Power plant, Substation construction and Transmission line, including of design, complete equipment, installation, Commissioningand after-sales service, and also design the complete Electrical Solutions according to customer's demand. We are mainly services to International State Power Board, Power Construction Contractor, Power Project Contractor, Factories and the Electric Power Project in the world.

In order to achieve the enterprise's strategic target---being stronger, larger, and superior, we continue to expand throughout the world's markets for power transmission and distribution area. And we also actively attach our team to competition, walking forward to the mission of "First-class worldwide electrical equipment supplier