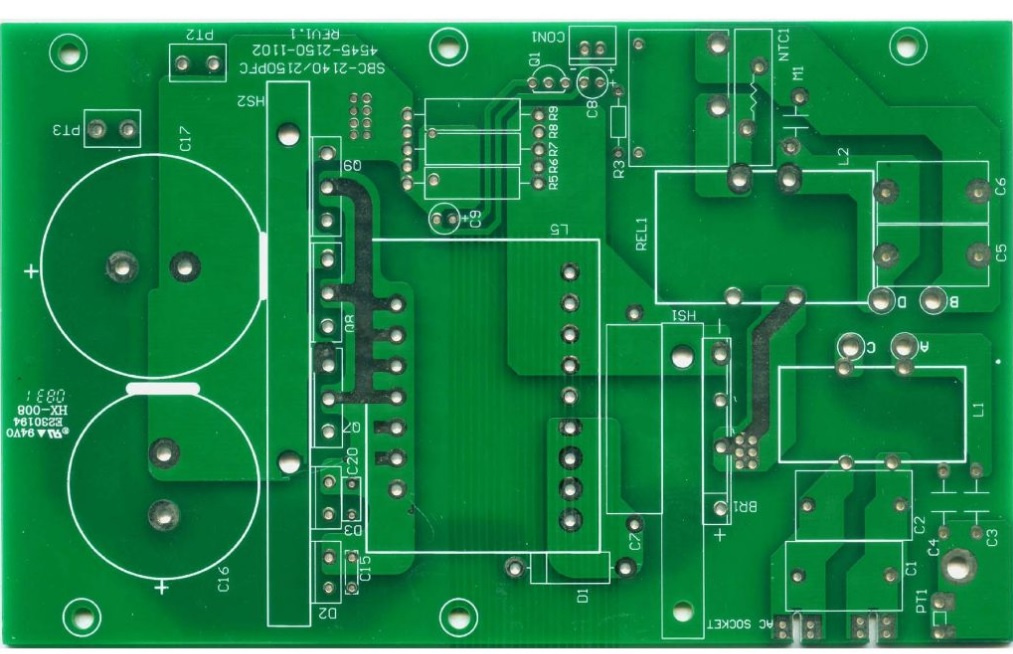

Two Layers Gold Plating Green Solder Mask Rigid PCB (MIC0485)

| Price: |

US $ 2.8-5/Piece |

| Trade Terms: |

FOB,CIF,EXW |

| Min Order: |

100/Piece |

| Pay Type: |

L/C,T/T,Western Union |

| Prod Model: |

MIC0485 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Printing: |

White Letters |

| Finishing: |

Gold Plating |

| Soldering Mask: |

Green |

| Layers: |

2 |

| Type: |

Rigid Circuit Board |

| Dielectric: |

FR-4 |

| Material: |

Paper Phenolic Copper Foil Substrate |

| Flame Retardant Properties: |

V0 |

| Base Material: |

Fr4 |

| Brand: |

Luphi |

Product Description

Item |

Description |

Technical capabilities |

1 |

Layers |

1-50 Layers |

2 |

Max. Board Size |

2000×800mm(79"×32") |

3 |

Material: |

FR-4,High TG FR4,Halogen Free Material, Rogers,Arlon,PTFE,Taconic,Isola, Ceramics, Aluminum, Copper base etc |

4 |

Max. Board Thickness |

330mil(8.4mm) |

5 |

Min. Inner Line Width / Space |

3mil(0.075mm) / 3mil(0.075mm) |

6 |

Min. Outer Line Width / Space |

3mil(0.75mm) / 3mil(0.075mm) |

7 |

Min. Finish Hole Size |

4mil(0.10mm) |

8 |

Max. Aspect ratio |

16:1 |

9 |

Min Via Hole Size & Pad |

via: dia. 0.2mm / pad: dia. 0.4mm ; HDI <0.10mm via |

10 |

Min Hole Tolerance |

±0.05mm(NPTH), ±0.076mm(PTH) |

11 |

Finished Hole Size Tolerance(PTH) |

±2mil(0.05mm) |

12 |

Finished Hole Size Tolerance(NPTH) |

±1mil(0.025mm) |

13 |

Hole Position Deviation Tolerance |

±2mil(0.05mm) |

14 |

Outline Tolerance |

±4mil(0.1mm) |

15 |

Min. S/M Pitch |

3mil(0.075mm) |

16 |

Insulation Resistance |

>1012 Ω Normal |

17 |

Thermal Shock |

288 ºC, 20 sec |

18 |

Warp and Twist |

≤0.5% |

19 |

Electric Strength |

>1.3kv/mm |

20 |

Solder Mask Hardness |

≥6H |

21 |

Flammability |

94V -0 |

22 |

Min Solder Mask Coverage |

0.05mm(2mil) |

22 |

Surface Finishing |

OSP,ENIG,Flash Gold,Immersion Tin,HASL,Tin Plating,Immersion Silver ,Carbon Ink, Peel-off Mask, Gold Fingers (30μ"), Immersion Silver (3~10u"), Immersion Tin (0.6~1.2um). |

24 |

V-Cut Angle |

30° 45° 60° , tolerance +/- 5° |

25 |

Min V-Cut Board Thickness |

0.75mm |

26 |

Min. Blind/Buried Via |

0.15mm (6mil) |

|

PCB Introduction:

A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, tracks or signal traces etched from copper sheets laminated onto a non-conductive substrate. It is also referred to as printed wiring board (PWB) or etched wiring board. A PCB populated with electronic components is a printed circuit assembly (PCA), also known as a printed circuit board assembly (PCBA).

PCBs are inexpensive, and can be highly reliable. They require much more layout effort and higher initial cost than either wire wrapor point-to-point construction, but are much cheaper and faster for high-volume production. Much of the electronics industry's PCB design, assembly, and quality control needs are set by standards that are published by the IPC organization.

Advanced Technology Products:

Backplanes, HDI boards, High-frequency boards, High TG boards, Halogen-free boards, Flexible and rigid-Flex boards, Hybrids, and any boards with applications in high-tech products.

40 layers PCB, 2mil line width spacing:

Our 13 years' manufacturing experience, high precision equipments and testing instruments enables VIT to produce 50 layers rigid boards and rigid-flex circuits up to 20 layers. Backplane thicknesses up to .276 (7mm), aspect ratios up to 20:1, 2/2 line/space and impedance controlled designs are produced daily.

Products and Technology Application:

Apply to communications, aerospace, defense, IT, medical equipment, precision test equipment and industrial control companies etc.

Standard Criteria for PCBs Processing: Inspection and test criteria will be based upon IPC-A-600 and IPC-6012, Class 2 unless otherwise specified on customer drawings or specifications.

PCB Design Service: VIT also can provide the PCB design service to our customers. Sometimes, our customers only give us a 2D file or just an idea, then we shall design the PCB, layout, and make the Gerber file for them.

Dongguan LuPhi Electronics Technology Co., Ltd. (short for LUPHI bellow) is established in 2008. It located in Ziliang High-Tech Industrial Park, Huaide, Humen of Dongguan. The factory area is about 3500 square meters. It close neighbors to Shenzhen, Guangzhou and Hongkong. To Shenzhen airport is just about 30 minutes and to Guangzhou Baiyun Airport is just about 1 hour. LUPHI is a newly high-tech enterprise for human interface technology and metal, plastic molding, electronics product development, design and assembly.

Our main business and products include designing and manufacturing various kinds of super big size membrane switches, membrane keypads, graphic overlays, membrane circuits, various kinds of backlit membrane keypads like the LED backlit membrane switches, EL backlit membrane switches, LGF backlit membrane switches, the high-tech capacitive membrane switches and nameplates, labels, PCBA, prototype to middle volume metal + plastic + electronics turnkey project assembly.

At the beginning of establishing of LUPHI, we made the factory planning as per the requirements of our customers from USA and Europe, and the international standard. We invested big money to get many new and high accuracy big size semi-auto silk screen printing machines, high-performance pneumatic punching machines, hot embossing machine, high accuracy laser cutting machine, auto die cutting machine etc. LUPHI always regards the quality as our life. We established our inner testing room. We have many high-grade testing machines and equipments in our testing room, like the life testing instruments, 2D measurement instrument, high-low temperature environment test equipment, friction tester, dropping tester, electrical function testing instruments, ink adhesion tester etc. In addition, we also have the high clean room and anti-static clean booth to ensure the product reliability and stability for those high-accuracy and anti-static required products. By such kind of advanced hardware facilities and our experienced quality management team to ensure that each batch delivery to meet our customers' high quality requirements.

We organize the various kinds of training to our employees regularly. For example the product knowledge training, operation and assembly training, quality sense training, fire prevention training etc. To ensure our workers have the skillful operation technique to meet our promise of the on time delivery to our customers from all of the world.

80% customers of LUPHI are from USA, Australia, UK, Germany, Austria, France, Italy, Belgium, Sweden, Russia, Ukraine etc. Countries and areas. We know the overseas customers' requirements and business procedures very well. On this basis, we established our own perfect business development, engineering development & design, artwork making, production and quality control system.

We promise to use high quality raw materials to ensure our products achieve the quality goal of our customers. For example, we use Autotype PET, Lexan PC from GE, Korea Changsung silver paste, ACHESON silver paste, Japan JUJO inks, Nicomatic, CJT connectors, 3M adhesive, Luxking spacers etc.

LUPHI is dedicated to be the standard founder and leader for the membrane switches industry in China!

Warmly welcome you to visit us and discuss business!

More >

Other Products with This Manufacturers