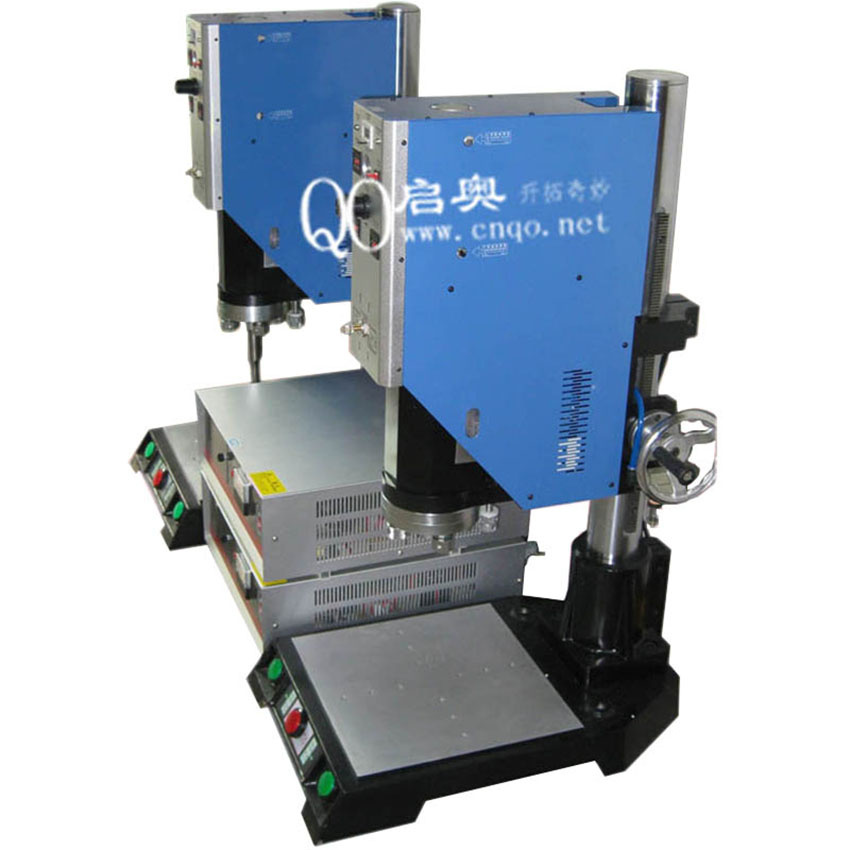

Ultrasonic Welding Machine, Durable, Low Rate of Bad

| Price: |

US $ 5000-8000/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

T/T |

| Prod Model: |

QO-2020YZ-J |

| Frequency: |

20kHz |

| Input Voltag: |

220V |

Product Description

Product Application

Used for toys, electronic, plastic bags and small rubber pieces of welding and forming.

Ultrasonic Welding designed for .ABS/PE/PC/PS/PVC/PP material Ultrasonic welding; ABS-PC complex welding, acrylic Ultrasonic welding

Optimization of the heat welding defects (yellowing, edge burning and blocking up).

•It is suitable for welding the thermal plastic such like: HDPE,PP,PE,ABS,PVC,PC,EVA,PMMA,PS,PP,PBT,PETG, and other plastic, also for fiber cotton, chemical fiber, metal hardware in the aspects of riveting, cutting, sealing, welding, spot welding, embossing, fixed position for files, melt welding

•According to customer needs to replace riveting, welding, embedded, removing process, relative to other traditional process (such as adhesives, hot welding or screw connection), has high production efficiency, good weld quality, environmental protection and energy saving advantages

• Portable operation, fast, clean, safe and stable

•It can Set the working time, the delay time and holding time according to the customer's demand,.

Customized welding machines notes:

1. what is the material of your welding product

2. what is the thickness of product

3. what is your request of welding, such as welding method, welding effect ......

4. If you have machine drawing, pls send to us.

5. It's better for you to post us your welding product, so that we can test by our machine and take a video for you

SPECIFICATION:

| | |

| QO-2015YZ-J | QO-2020YZ-J | QO-1526YZ-J | QO-1532YZ-J | QO-1542YZ-J |

Input power | 1500W | 2000W | 2600W | 3200W | 4200W |

Frequency | | |

| 220V | |

Moving distance of active horn | |

utput time | |

| |

Welding area | 200mm | 220mm | 250mm | 310mm | 400mm |

Compressor | |

Net weight | 120kg | 124kg | 128kg | 132kg | 140kg

|

Main Features

Split type ultrasonic welding machine features

1. There is little demand for workspace because of the cabinet is separate from the operating desk

2. New improvement, better performance

3. Use different moulds, you can realize different welding application

4. All design and parameter above are adjustable upon customer¡¯s special requirement

5. It original piezoelectric ceramic transducer has a strong and stable output

6. Titanium alloy horn, durable

7. Frequency modulation and frequency automatic compensation circuit

8. Set up soft starting circuit to avoid damage to the mold

9. A full set of quality imported components, quality assurance

10.High welding efficiency, low rate of failureDetailed Images

Packing & Delivery

Our company supplies different kinds of products. High quality and reasonable price.

SHENZHEN QIAO EQUIPMENT Co., Ltd. We professional production and sales high frequency machine, ultrasonic machine, and cylinder machine series equipment.

Currently, the company's products mainly include the following aspects:

A high frequency class: High frequency machine is divided into high-frequency welding machines, high frequency fusing machine, high frequency canvas, double-headed machine of high-frequency, high-frequency carpet welding machine, high frequency blister packing machine, high frequency toothbrush packing machine, high frequency plastic welding machines, high frequency synchronous fusing machine, high frequency insole machine. High frequency plastic welding machine Scope: Footwear, trademark, note paper, raincoats, umbrellas, purses, handbags, beach bags, stationery, designer, inflatable toys, water beds, steam machine cushion, sun visors, door panels, sided blister packaging sealing, suitable for heat sealing blister with paper card packing battery, toothbrush, electric tools, toys, dolls and other paper cards with plastic covers, blister packaging, blister packaging and blister sealing. High frequency metal welding machine, high frequency heating machine, mainly for the heating of the metal material with metal and plastic implants, With accessories, welding metal to metal.

B the packaging class machine: Packaging machine is mainly including vacuum packaging machine, shrink packing machine, stick put oneself in packaging machine and so on, but the principle is similar, all is deflated after sealing as the main characteristics, but they use tools and according to different products. Vacuum packing machine points single chamber vacuum packaging machine, double chamber vacuum packaging machine, the suction type vacuum packing machine. Suitable for food, agricultural products, chemical raw materials, arts and crafts, metal products and electronic, electrical components etc packing. Synthetic packaging of the cylinder machine, cylinder curling machine, cylinder welding bottom machine or sealing machine, brush glue machine, folding box machine, etc.

C ultrasonic machine types: Ultrasonic machine mainly include ultrasonic plastic welding, ultrasonic CD set of machine, ultrasonic cleaning machine, ultrasonic spot welding machine, ultrasonic lace machine, ultrasonic metal welding machine, etc. Ultrasonic welding machine is suitable for: ABS, PC, PS, acrylic, mobile phone sets, computer keyboard, U disk, mobile phone charger, plastic cardcase, plastic folder, stationery and plastic welding. Spot welding machine is suitable for spot welding machine used to mask elastic ribbon point together, non-woven bag pull-tab point close and widely used in diapers, bra, zipper products point together.

We specialize in a variety of automation, intelligent high-precision, high-frequency, ultrasonic equipment, research and development, the comprehensive development of a variety of welding technology and packaging plastic welding non-standard equipment. Reliable product quality, high technology content, the main parts are imported from Europe, the United States, Japan and other regions and countries, strong product development capabilities, and improve the quality management system and after-sales service system, for many customers at home and abroad to provide production well, the superior performance of production equipment and services. Company for the purpose to the pursuit of quality, integrity services; Customer satisfaction as the goal.

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

More >

Other Products with This Manufacturers