| Prod Model: |

XVM 50-6 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Vibration Force: |

0-50kn |

| Power: |

3.7kw |

| Current: |

8.1A |

| Insulation Class: |

F |

| Protective Grade: |

IP55 |

| Rated Speed: |

1000 Rpm |

| Weight: |

165kg |

| Phase: |

3 |

| Noise: |

65dB |

| Company Nature: |

OEM |

| Function: |

Driving |

| Certification: |

CE,SGS |

| Brand: |

Yongqing |

Product Description

Product descriptionXVM Series high frequency AC electric vibrating motor(XVM 50-6)

Our XVM series vibration motor is designed as a high-end vibrating motor. It is available in several types with different specifications, while the most powerful one comes with an exciting force of 300 KN, and is driven by 30kw power. The rotor and stator are made of excellent silicon steel sheet. The heat dissipation is limited. High purity copper wire is used for better performance of the motor.

Specification Sheet| Model | Rated speed

[rpm] | Vibrating Force

[KN] | Power

[kw] | Current

(A) | efficiency | weight

[kg] | Bolt |

| XVM0.7-2 | 3000 | 0.7 | 0.15 | 0.38 | 70 | 14 | M12 |

| XVM1.5-2 | 1.5 | 0.15 | 0.38 | 70 | 15 | M12 |

| XVM2.5-2 | 2.5 | 0.25 | 0.58 | 76 | 16 | M12 |

| XVM 5-2 | 5 | 0.40 | 1.01 | 72 | 23 | M16 |

| XVM 8-2 | 8 | 0.75 | 1.76 | 74 | 42 | M20 |

| XVM 16-2 | 16 | 1.10 | 2.80 | 70 | 58 | M20 |

| XVM 20-2 | 25 | 1.80 | 4.30 | 71 | 60 | M20 |

| XVM 30-2 | 32 | 2.20 | 5.10 | 73 | 95 | M20 |

| XVM 45-2 | 50 | 3.50 | 8.18 | 73 | 200 | M24 |

| XVM 1.2-4 | 1500 | 1.2 | 0.07 | 0.30 | 60 | 14 | M12 |

| XVM 2.5-4 | 2 | 0.10 | 0.32 | 66 | 18 | M12 |

| XVM 5-4 | 5 | 0.20 | 0.65 | 70 | 27 | M16 |

| XVM 8-4 | 8 | 0.40 | 1.14 | 73 | 44 | M20 |

| XZM-10-4 | 10 | 0.5 | 1.14 | 74 | 46 | M20 |

| XVM 16-4 | 16 | 0.75 | 2.08 | 74 | 65 | M20 |

| XVM 20-4 | 20 | 1.1 | 2.6 | 74 | 67 | M20 |

| XVM 25-4 | 25 | 1.5 | 3.0 | 74 | 111 | M20 |

| XVM 32-4 | 32 | 2.00 | 4.73 | 77 | 116 | M20 |

| XVM-40-4 | 40 | 2.2 | 5.0 | 73 | 135 | M20 |

| XVM 50-4 | 5 | 2.50 | 6.25 | 73 | 240 | M24 |

| XVM 75-4 | 75 | 4.00 | 10.14 | 74 | 270 | M30 |

| XVM100-4 | 100 | 6.50 | 16.88 | 71 | 390 | M30 |

| XVM120-4 | 120 | 8.00 | 19.40 | 76 | 510 | M36 |

| XVM140-4 | 140 | 10.00 | 24.16 | 75 | 580 | M36 |

| XVM160-4 | 160 | 10.00 | 24.16 | 75 | 620 | M36 |

| XVM2.5-6 | 1000 | 2.5 | 0.20 | 0.70 | 71 | 28 | M16 |

| XVM 5-6 | 5 | 0.40 | 1.23 | 74 | 37 | M16 |

| XVM 8-6 | 8 | 0.55 | 1.5 | 74 | 51 | M20 |

| XVM 10-6 | 10 | 0.75 | 2.18 | 78 | 69 | M20 |

| XVM 16-6 | 16 | 1.10 | 3.03 | 78 | 83 | M20 |

| XVM 20-6 | 20 | 1.50 | 4.10 | 81 | 117 | M20 |

| XVM 30-6 | 30 | 2.20 | 6.10 | 80 | 165 | M20 |

| XVM 40-6 | 40 | 3.00 | 7.40 | 84 | 189 | M20 |

| XVM 50-6 | 50 | 3.70 | 9.60 | 83 | 230 | M24 |

| XVM 75-6 | 7.5 | 5.50 | 12.60 | 81 | 290 | M30 |

| XVM100-6 | 100 | 7.50 | 17.93 | 81 | 450 | M30 |

| XVM120-6 | 120 | 9.50 | 21.70 | 83 | 550 | M36 |

| XVM140-6 | 140 | 9.50 | 21.70 | 83 | 615 | M36 |

| XVM160-6 | 160 | 12.00 | 27.37 | 81 | 675 | M36 |

| XVM180-6 | 180 | 14.00 | 31.87 | 81 | 860 | M42 |

| XVM 5-8 | 750 | 5 | 0.40 | 1.62 | 68 | 74 | M20 |

| XVM 10-8 | 10 | 0.75 | 2.90 | 72 | 117 | M20 |

| XVM 16-8 | 16 | 1.50 | 4.02 | 80 | 172 | M20 |

| XVM 20-8 | 20 | 2.20 | 5.93 | 80 | 190 | M20 |

| XVM 30-8 | 30 | 3.00 | 8.10 | 82 | 230 | M24 |

| XVM 50-8 | 50 | 4.00 | 10.60 | 82 | 290 | M30 |

| XVM 75-8 | 75 | 6.50 | 17.10 | 81 | 450 | M30 |

| XVM100-8 | 100 | 8.50 | 21.80 | 81 | 690 | M36 |

| Small 3 phase AC electric vibrating motor-XVM |

| Model | XVM electric vibrating motor |

| Excitation Force | 0.7KN-200KN |

| Poles | 2 pole/ 4 pole/ 6 pole/ 8 pole |

| Rotation speed | 3000RPM/1500rpm/1000rpm/750rpm |

| Power | 0.15KW-20KW |

| Workable temperature | -20~ -40°C |

| Working Height | Below 1000m |

| Voltage | 220/240/380/415/450V are all available |

| Frequency | 50HZ or 60HZ |

| Protective grade | IP55 or IP65 |

| Phase | 3 |

| Way of connection | Y |

| Insulating grade | B or F |

| Way of working | Continuous |

| Type | AC |

Feature:

1. Advanced design

All the parameter calculation and design optimization are conducted by computer. Our precise manufacturing techniques and rigid quality control system can guarantee that the related components work together on a desirable condition during the operation of our vibration motor.

2. Special electromagnetic design

The rotor and stator of the motor are both made of premium silicone steel sheet with great magnetic conductivity, remarkably reducing the eddy-current loss of the iron core. Thus a powerful starting torque can be achieved, making the rotor reach the operation speed in as short time.

3. Heavy load bearing

All the bearings of the vibration motor are specially designed heavy load bearings, which can endure and transfer radical exciting force and axial load. The thermal dissipation performance is excellent. The double sealing design gives the bearing compartment great dustproof property. The high temperature resistant lithium-based grease is adopted for longer service life of the bearings.

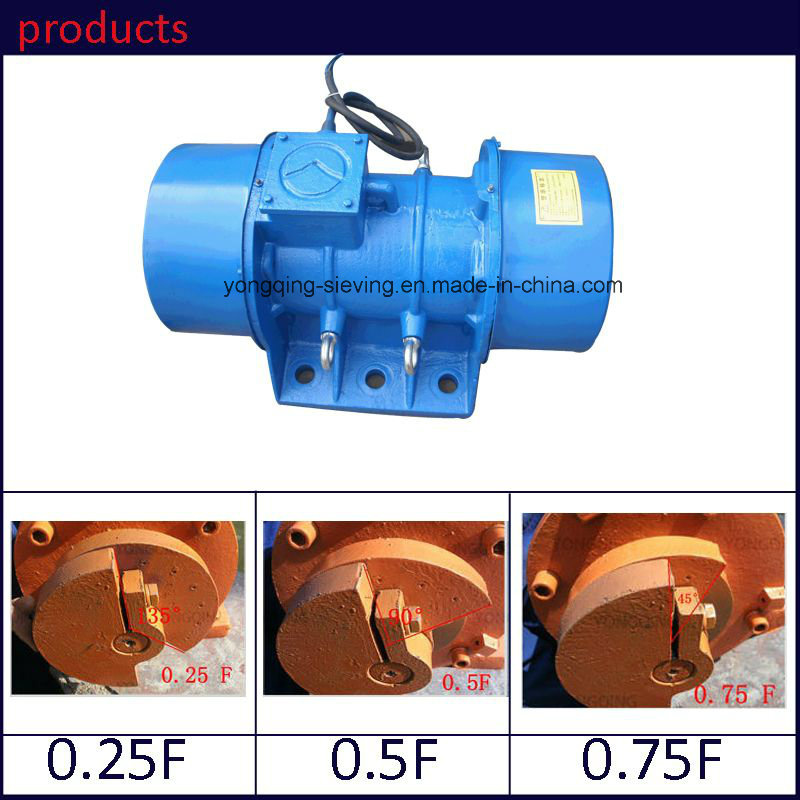

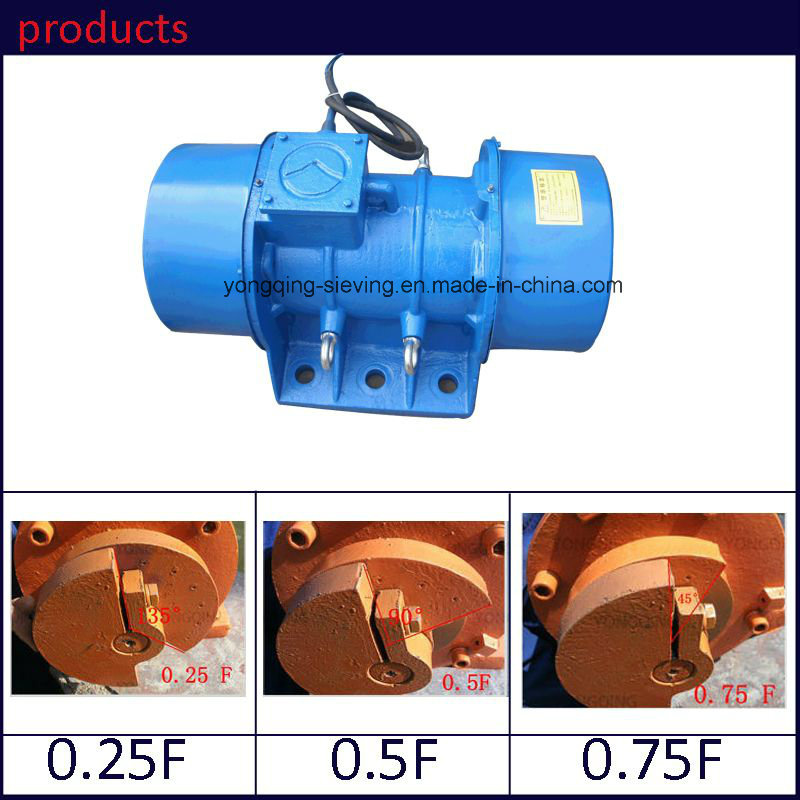

4.Stepless adjustment

A precise dial is marked on the eccentric blocks at the both sides of the vibration motor. So it is easy adjust the exciting force and working torque steplessly from Zero to the maximum values.

5. Flexible power supply.

Our XVM series AC power vibration motor is designed for working on different kinds of three-phase AC power, including the 220V/380V power in China and Europe, 230V/460V and 60HZ power in the U.S., and the 220V 50HZ/60HZ in Japan. Actually, this motor can be used almost everywhere around the world.

RFQ

If you interested in our products, please feel free to contact us. We will help choose the best material equipment for you. So pls provide the follow information.

1. Please advice your usage.

2. Please advice the power you need

3. Please advice the rated speed.

4. Please advice the voltage you use.

5. Other special requirement.

Wecome all customers to come to visit our factory

As a Chinese screening equipment, conveying unit, and feeding device provider, Yongqing Screen Machine Co., Ltd. Was founded in Xinxiang City, Henan Province, China, in Oct. 2006. We have rich experience in the product research, development, manufacturing, and professional service. Our products include vibrating screen, vibrating motor, belt conveyor and so on. They can be widely used for food screening, impurity removing from ceramic glaze, ore processing, and so on. If clients need special products, our R&D department can either update our existing products or design new products according to the requirements.

We have more than 5 years of international trade experience, while our screening machines and related accessories have entered more than 50 countries and regions. Currently, you can find our first level agencies in Indonesia and Portugal.

Our premium screening equipment, conveying equipment and feeding machine have been widely welcomed by our customers for our processional production techniques, considerate support and service, and reasonable price, In addition, we also provide various services like project design, production technique design, non-standard product design, and on-site technical support.

We have established an efficient quality control system conforming to ISO9001 standard, covering from raw material purchasing, components processing, product assembly, up to the finished products tests. Three quality inspection procedures for the production department, quality insurance department, and our customers, respectively, have been continuously optimized to guarantee the excellent product quality.

In spite of the successes we have accomplished, we will never stop progressing and providing better products. Just contact us if you are interested in our products or have any advice for us.