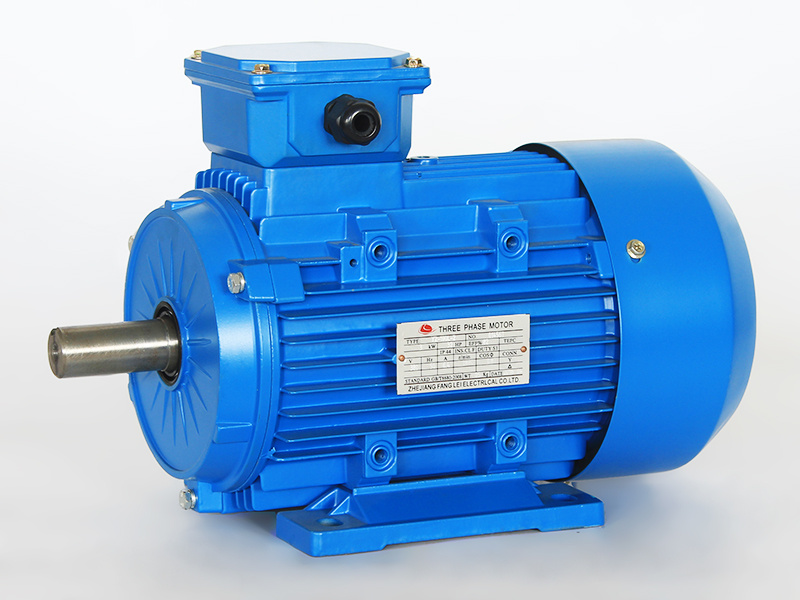

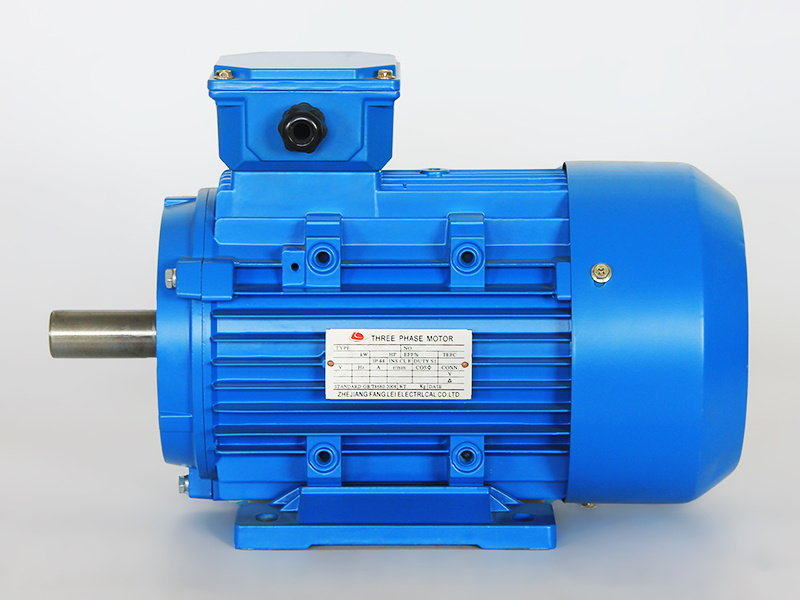

Ye2 Three Phase 18.5kw Electro-Magnetic Speed-Governing Asynchronous Motor

| Price: |

Negotiable/Box |

| Min Order: |

1/Box |

| Pay Type: |

L/C,T/T |

| Prod Model: |

YE2 |

| Application: |

Power Tools |

| Operating Speed: |

High Speed |

| Number Of Stator: |

Three-Phase |

| Species: |

Y, Y2 Series Three-Phase |

| Rotor Structure: |

Squirrel-Cage |

| Casing Protection: |

Closed Type |

| Number Of Poles: |

2-8 |

| Certification: |

Ce |

Product Description

Detailed Info

technical parameter

| GE2 (IE2 aluminum) series of technical parameters |

| NO. | Model | Output

kW | Speed | Amps | EFF. | P.F. | LRT/RLT | LRA/RLA | BDT/RLT | Noise LwdB | Voltage |

| r/min | A | % | cosφ | A | V |

| 1 | YE2-80M1-2 | 0.75 | 2850 | 1.7 | 77.4 | 0.82 | 2.3 | 6.8 | 2.3 | 62 | 400 |

| 2 | YE2-80M2-2 | 1.1 | 2870 | 2.4 | 79.6 | 0.83 | 2.3 | 7.1 | 2.3 | 62 | 400 |

| 3 | YE2-90S-2 | 1.5 | 2880 | 3.2 | 81.3 | 0.84 | 2.3 | 7.3 | 2.3 | 67 | 400 |

| 4 | YE2-90L-2 | 2.2 | 2880 | 4.5 | 83.2 | 0.85 | 2.3 | 7.6 | 2.3 | 67 | 400 |

| 5 | YE2-100L1-2 | 3 | 2880 | 5.9 | 84.6 | 0.87 | 2.2 | 7.8 | 2.3 | 74 | 400 |

| 6 | YE2-112M-2 | 4 | 2900 | 7.6 | 85.8 | 0.88 | 2.3 | 8.1 | 2.3 | 77 | 400 |

| 7 | YE2-132S1-2 | 5.5 | 2910 | 10.4 | 87 | 0.88 | 2.2 | 8.2 | 2.3 | 79 | 400 |

| 8 | YE2-132S2-2 | 7.5 | 2910 | 13.8 | 88.1 | 0.89 | 2.2 | 7.8 | 2.3 | 79 | 400 |

| 9 | YE2-160M1-2 | 11 | 2940 | 20 | 89.4 | 0.89 | 2.2 | 7.9 | 2.3 | 81 | 400 |

| 10 | YE2-160M2-2 | 15 | 2940 | 26.9 | 90.3 | 0.89 | 2.2 | 8 | 2.3 | 81 | 400 |

| 11 | YE2-160L-2 | 18.5 | 2940 | 33 | 90.9 | 0.89 | 2.2 | 8 | 2.3 | 81 | 400 |

| 12 | YE2-180M-2 | 22 | 2950 | 39.1 | 91.3 | 0.89 | 2.2 | 8.1 | 2.3 | 83 | 400 |

| 13 | YE2-80M2-4 | 0.75 | 1420 | 1.8 | 79.6 | 0.76 | 2.3 | 6.4 | 2.3 | 56 | 400 |

| 14 | YE2-90S-4 | 1.1 | 1420 | 2.6 | 81.4 | 0.77 | 2.3 | 6.6 | 2.3 | 59 | 400 |

| 15 | YE2-90L-4 | 1.5 | 1420 | 3.5 | 82.8 | 0.78 | 2.3 | 6.7 | 2.3 | 59 | 400 |

| 16 | YE2-100L1-4 | 2.2 | 1440 | 4.7 | 84.3 | 0.8 | 2.3 | 7.3 | 2.3 | 64 | 400 |

| 17 | YE2-100L2-4 | 3 | 1440 | 6.2 | 85.5 | 0.81 | 2.3 | 7.5 | 2.3 | 64 | 400 |

| 18 | YE2-112M-4 | 4 | 1445 | 8.1 | 86.6 | 0.81 | 2.3 | 7.5 | 2.3 | 65 | 400 |

| 19 | YE2-132S-4 | 5.5 | 1450 | 11.1 | 87.7 | 0.82 | 2 | 7.5 | 2.3 | 71 | 400 |

| 20 | YE2-132M-4 | 7.5 | 1450 | 14.7 | 88.7 | 0.83 | 2 | 7.3 | 2.3 | 71 | 400 |

| 21 | YE2-160M-4 | 11 | 1470 | 21.3 | 89.8 | 0.83 | 2.2 | 7.4 | 2.3 | 73 | 400 |

| 22 | YE2-160L-4 | 15 | 1470 | 28.4 | 90.6 | 0.84 | 2.2 | 7.5 | 2.3 | 73 | 400 |

| 23 | YE2-180M-4 | 18.5 | 1470 | 34.4 | 91.2 | 0.85 | 2.2 | 7.6 | 2.3 | 76 | 400 |

| 24 | YE2-180L-4 | 22 | 1470 | 40.8 | 91.6 | 0.85 | 2.2 | 7.7 | 2.3 | 76 | 400 |

| 25 | YE2-90S-6 | 0.75 | 930 | 2 | 75.9 | 0.71 | 2 | 5.8 | 2.1 | 57 | 400 |

| 26 | YE2-90L-6 | 1.1 | 930 | 2.8 | 78.1 | 0.72 | 2 | 5.9 | 2.1 | 57 | 400 |

| 27 | YE2-100L1-6 | 1.5 | 930 | 3.7 | 79.8 | 0.72 | 2 | 5.9 | 2.1 | 61 | 400 |

| 28 | YE2-112M-6 | 2.2 | 945 | 5.4 | 81.8 | 0.72 | 2.1 | 6.2 | 2.1 | 65 | 400 |

| 29 | YE2-132S-6 | 3 | 960 | 7.1 | 83.3 | 0.72 | 2 | 6.4 | 2.1 | 69 | 400 |

| 30 | YE2-132M1-6 | 4 | 965 | 9.2 | 84.6 | 0.74 | 2 | 6.6 | 2.1 | 69 | 400 |

| 31 | YE2-132M2-6 | 5.5 | 965 | 12.3 | 86 | 0.75 | 2 | 6.8 | 2.1 | 69 | 400 |

| 32 | YE2-160M-6 | 7.5 | 970 | 15.9 | 87.2 | 0.78 | 2.1 | 6.8 | 2.1 | 73 | 400 |

| 33 | YE2-160L-6 | 11 | 970 | 22.7 | 88.7 | 0.79 | 2.1 | 6.9 | 2.1 | 73 | 400 |

| 34 | YE2-180L-6 | 15 | 980 | 29.8 | 89.7 | 0.81 | 2 | 7.3 | 2.1 | 73 | 400 |

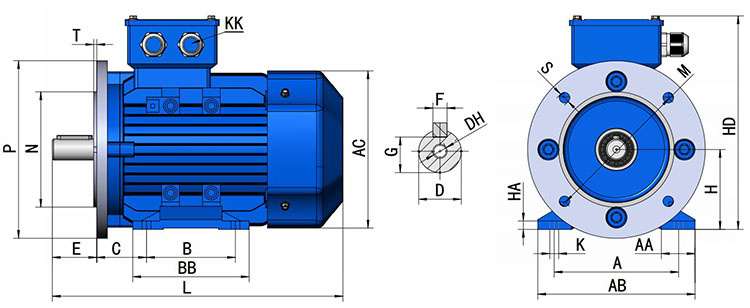

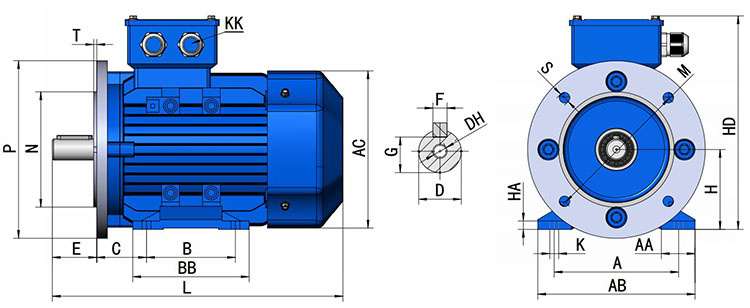

| Shape and installation dimensions (IMB35) |

| FRAME | POLES | A | A/2 | B | C | D | E | F | G | H | K | M | N | P | S | T | FLANGE | AB | AC | AD | HD | L | DH* |

| SIZE | HOLES |

| 80M | 2 4 6 | 125 | 62.5 | 100 | 50 | 19 | 40 | 6 | 15.5 | 80 | 10 | 165 | 130 | 200 | 12 | 3.5 | 4 | 153 | 157 | 140 | 220 | 295 | M6×16 |

| 90S | 2 4 6 | 140 | 70 | 100 | 56 | 24 | 50 | 8 | 20 | 90 | 10 | 165 | 130 | 200 | 12 | 3.5 | 4 | 177 | 177 | 150 | 240 | 327 | M8×19 |

| 90L | 2 4 6 | 140 | 72 | 125 | 56 | 24 | 50 | 8 | 20 | 90 | 10 | 165 | 130 | 200 | 12 | 3.5 | 4 | 177 | 177 | 150 | 240 | 357 | M8×19 |

| 100L | 2 4 6 | 160 | 80 | 140 | 63 | 28 | 60 | 8 | 24 | 100 | 12 | 215 | 180 | 250 | 15 | 4 | 4 | 196 | 197 | 167 | 267 | 403 | M10×22 |

| 112M | 2 4 6 | 190 | 95 | 140 | 70 | 28 | 60 | 8 | 24 | 112 | 12 | 215 | 180 | 250 | 15 | 4 | 4 | 226 | 219 | 177 | 289 | 430 | M10×22 |

| 132S | 2 4 6 | 216 | 108 | 140 | 30 | 38 | 30 | 10 | 33 | 132 | 12 | 265 | 230 | 300 | 15 | 4 | 4 | 260 | 258 | 196 | 328 | 460 | M12×28 |

| 132M | 2 4 6 | 216 | 108 | 178 | 30 | 38 | 80 | 10 | 33 | 132 | 12 | 265 | 230 | 300 | 15 | 4 | 4 | 260 | 258 | 196 | 328 | 499 | M12×28 |

| 160M | 2 4 6 | 254 | 127 | 210 | 108 | 42 | 110 | 12 | 37 | 160 | 15 | 300 | 250 | 350 | 19 | 5 | 4 | 314 | 314 | 255 | 415 | 615 | M16×36 |

| 160L | 2 4 6 | 254 | 127 | 254 | 108 | 42 | 110 | 12 | 37 | 160 | 15 | 300 | 250 | 350 | 19 | 5 | 4 | 314 | 314 | 255 | 415 | 660 | M16×36 |

| 180M | 2 4 6 | 279 | 140 | 241 | 121 | 48 | 112 | 14 | 42.5 | 180 | 15 | 300 | 250 | 350 | 19 | 5 | 4 | 355 | 356 | 270 | 450 | 700 | M16×36 |

| 180L | 2 4 6 | 279 | 140 | 279 | 121 | 48 | 110 | 14 | 42.5 | 180 | 15 | 300 | 250 | 350 | 19 | 5 | 4 | 355 | 356 | 270 | 450 | 740 | M16×36 |

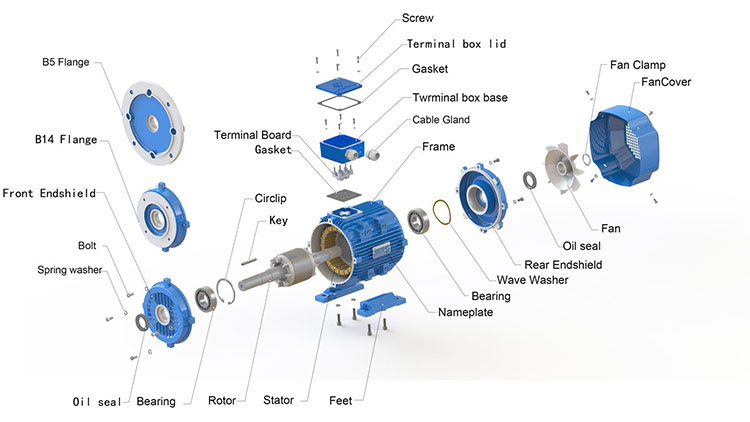

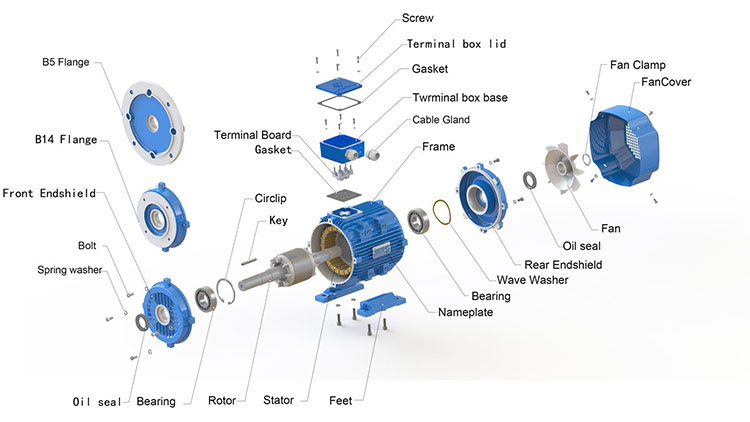

| GE2 (IE2 aluminum) bearing specifications |

|

| Dimensions | series | Shaft extension | Non-shaft end |

| 80 | 2-4 | 6204-2RZ | 6204-2RZ |

| 90 | 2-6 | 6205-2RZ | 6205-2RZ |

| 100 | 2-6 | 6206-2RZ | 6206-2RZ |

| 112 | 2-6 | 6306-2RZ | 6306-2RZ |

| 132 | 2-6 | 6308-2RZ | 6308-2RZ |

| 160 | 2-6 | 6309-2RZC3 | 6309-2RZC3 |

| 180 | 2-6 | 6311C3 | 6311C3 |

| The main terminal box data |

|

| Junction box Binning | Base range | Maximum full load current | Line pore size |

| 1 | H80 | 2.6 | 2×M20×15 |

| 2 | H90-100 | 6.8 | 2×M25×1.5 |

| 3 | H112-132 | 15.4 | 2×M35×1.5 |

| 4 | H160-180 | 42.5 | 2×M40×1.5 |

Zhejiang Fanglei Machine & Electric Co., Ltd. is located in Zhejiang, East China Sea in Taizhou. Ointly established the production of small and medium-sized production base for kinds of electric motors. The company focus on R & D and production of the wider use of technology, advanced small and medium-sized electric motors for domestic and foreign markets, the main products are in line with the international IEC standard three-phase asynchronous motors Y series cast iron motor and Y2 series with cast iron and aluminum housing motor

History: 25 years experience of manufacturing stator, motor, water pumps;

Scale: Covers working area of 6, 000 square meters. Have more than 200 employees;

Technology: A group of professional technical engineers and a strong R&D team;

Management: Scientific management and strict quality control system;

Equipments: Advanced automatic production line and test equipment;

Innovation: Continuously diversify products range to satisfy customers'needs, Production capacity: 30, 000 PCS/month;

Marketing network: Europe, Asia, Africa, America, etc;

Certificate: CE, GS, RoHS, IS09001: 2008,

The company established a strong R & D team to continuously optimize the product design and manufacturing processes, improve quality control and advanced production testing equipment, with the characteristics of modern management model, the company strictly in accordance with international standards ISO9001: 2008 quality system

More >

Other Products with This Manufacturers