1.8/3kv Medium Voltage Power Cables Single Core Cables to IEC 60502

| Price: |

US $ 0.3-18/Meter |

| Min Order: |

500/Meter |

| Pay Type: |

L/C,T/T |

| Prod Model: |

N2XSY, N2XSRY |

| Rated Voltage: |

1.8/3kv |

| Number Of Core: |

1 |

| Refer Standard: |

IEC 60502-1 |

| Application: |

Power Station |

| Voltage: |

Low and Medium Voltage Cable |

| Current: |

DC & AC |

| Insulation Material: |

XLPE |

| Certification: |

CE |

| Wire Core Material: |

Cu or Al |

| Model: |

Yjv Yjlv Yjy Yjly |

| Brand: |

Jl |

Product Description

1.8/3kv Medium Voltage Power Cables Single Core Cables StandardsIEC 60502 Part 1(1.8/3KV)1.8/3kv Medium Voltage Power Cables Single Core Cables Application

The single core cables are designed for distribution of electrical power with nominal voltage Uo/U ranging from 1.8/3KV to 26/35KV and frequency 50Hz. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

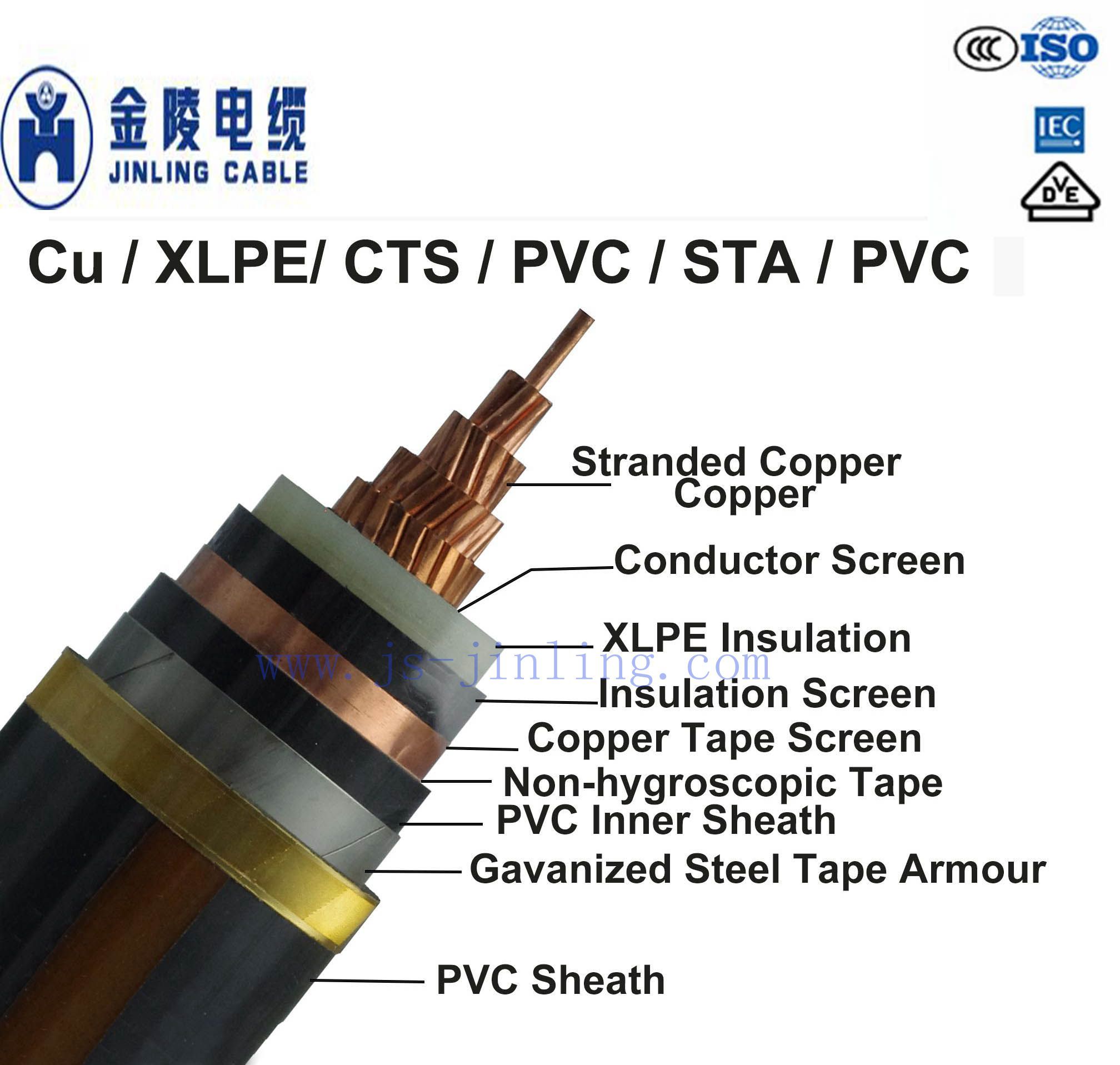

1.8/3kv Medium Voltage Power Cables Single Core Cables Construction

Conductor: Plain annealed copper or aluminium complying with IEC 60228 class 1 or 2.

Conductor Screen: The conductor screen consists of an extruded layer of non metallic, semi-conducting compound firmly bonded to the insulation to exclude all air voids.

Insulation: Insulation is of polyvinyl chloride (PVC) intended for 1.8/3KV and 3.6/6KV cables, cross-linked polyethylene compound (XLPE)

Insulaton Screen: It will consist of a layer of copper wires applied helically with overlap over insulation screen. Other combinations of metallic screens base on customs demand.

Separation Sheath (for armoured cable): The separation sheath comprises a layer of extruded PVC, PE or LSZH, applied under the armour .Lapped Bedding : The lapped bedding consists of Polyester non woven fabrics .The thickness is1.5mm

Armour (for armoured cable): The armour consists of round galvanized

steel wire armour applied helically over an extruded separation sheath and double steel Tape Armour.Over Sheath: Overall sheath comprises a layer of extruded thermoplastic compound (PVC, PE or LSZH can be offered as an option.) Installation and operation condition of cableOperating Temperature: up to 70°C (PVC insulation); up to 90°C (XLPE or EPR insulation)

Temperature Range: -5°C ( PVC sheath ); -20°C ( PE sheath )

Short Circuit Temperature( 5 seconds maximum duration ): 140-160°C (PVC insulation);

250°C (XLPE)

Bending Radius: 12 x OD

Current Rating Conditions:

Ground Temperature: 20°C

Ambient Temperature (air): 30°C

Depth of Soil: 0.8m

Thermal Resistance of Soil: 1.5K•m/W| Rated Voltage Uo/U | Operating Voltage (Um) | Testing Voltage

(rms) |

| 1.8/3KV | 3.6KV | 6.5KV |

1.8/3kv(Um=3.6KV) Power Cables Single Core Cables Dimensional Data| Nom.Cross-Section Area | | Unarmoured Cables | Steel Wire Armoured Cables |

|

| Nom.Insulation Thickness | Copper Tape Thickness | Copper Wire Screen Area* | Nom.Sheath Thickness | Approx.Overall Diameter | Approx.Weight | Nom.Bedding Thickness | Armour Wire Size | Nom.Sheath Thickness | Approx.Overall Diameter | Approx.Weight |

|

| CU | AL | CU | AL |

| mm2 | mm | mm | mm2 | mm | mm | kg/km | mm | mm | mm | mm | kg/km |

| 10 | 2 | 0.1 | 16 | 1.8 | 13 | 240 | 180 | 1.2 | 1.6 | 1.8 | 18 | 460 | 400 |

| 16 | 2 | 0.1 | 16 | 1.8 | 13 | 300 | 200 | 1.2 | 1.6 | 1.8 | 19 | 530 | 430 |

| 25 | 2 | 0.1 | 16 | 1.8 | 15 | 410 | 250 | 1.2 | 1.6 | 1.8 | 20 | 650 | 500 |

| 35 | 2 | 0.1 | 16 | 1.8 | 16 | 510 | 300 | 1.2 | 1.6 | 1.8 | 21 | 780 | 560 |

| 50 | 2 | 0.1 | 16 | 1.8 | 17 | 640 | 350 | 1.2 | 1.6 | 1.8 | 22 | 930 | 640 |

| 70 | 2 | 0.1 | 16 | 1.8 | 19 | 850 | 440 | 1.2 | 1.6 | 1.8 | 24 | 1170 | 750 |

| 95 | 2 | 0.1 | 16 | 1.8 | 20 | 1130 | 540 | 1.2 | 1.6 | 1.8 | 26 | 1460 | 870 |

| 120 | 2 | 0.1 | 16 | 1.8 | 22 | 1370 | 630 | 1.2 | 1.6 | 1.8 | 27 | 1730 | 990 |

| 150 | 2 | 0.1 | 25 | 1.8 | 23 | 1650 | 730 | 1.2 | 1.6 | 1.8 | 29 | 2030 | 1110 |

| 185 | 2 | 0.1 | 25 | 1.8 | 25 | 2010 | 860 | 1.2 | 1.6 | 1.9 | 30 | 2430 | 1280 |

| 240 | 2 | 0.1 | 25 | 1.8 | 27 | 2570 | 1050 | 1.2 | 1.6 | 2 | 33 | 3040 | 1530 |

| 300 | 2 | 0.1 | 25 | 1.8 | 29 | 3160 | 1250 | 1.2 | 2 | 2.1 | 36 | 3760 | 1860 |

| 400 | 2 | 0.1 | 35 | 1.9 | 33 | 3980 | 1560 | 1.2 | 2 | 2.2 | 39 | 4660 | 2230 |

| 500 | 2.2 | 0.1 | 35 | 2.1 | 35.5 | 4910 | 1905 | 1.3 | 2.5 | 2.5 | 43 | 5930 | 2930 |

| 630 | 2.4 | 0.1 | 35 | 2.2 | 39.7 | 6340 | 2420 | 1.4 | 2.5 | 2.6 | 49 | 7370 | 3430 |

| 800 | 2.6 | 0.1 | 50 | 2.3 | 44.5 | 7890 | 2980 | 1.4 | 2.5 | 2.7 | 52 | 9070 | 4230 |

| 1000 | 2.8 | 0.1 | 50 | 2.5 | 49.4 | 9890 | 3700 | 1.5 | 2.5 | 2.9 | 56 | 11100 | 4950 |

1.8/3kv(Um=3.6KV) Power Cables Single Core Cables Electrical Data| Nom.Cross-Section Area | D C Resistance

CU / AL | A C Resistance

CU / AL | Short Circuit Rating of Conductor

CU / AL

(1 sec) | Capacitance | Charging Current | Short Circuit Rating of Copper Wire Screen

(1 sec) | Short Circuit Rating of Copper Tape Screen

(1 sec) | Reactance | Inductance | Impedance |

| Trefoil | Flat | Trefoil | Flat | Trefoil | Flat Spaced |

| Spaced | Spaced | cu | AL | cu | AL |

| mm2 | µΩ/m | µΩm | kA | pF/m | mA/m | kA | kA | µΩ/m | nH/m | µΩ/ m | µΩ/ m |

| 10 | 1830/3080 | 2330/3920 | 1.4/0.9 | 182 | 0.27 | 2.6 | 0.2 | 151 | 201 | 384 | 558 | 2332 | 3846 | 2332 | 3840 |

| 16 | 1150/1910 | 1460/2420 | 2.2/1.4 | 201 | 0.29 | 2.6 | 0.3 | 140 | 193 | 362 | 546 | 1462 | 2411 | 1478 | 2420 |

| 25 | 727/1200 | 927/1538 | 3.6/2.3 | 222 | 0.32 | 2.6 | 0.3 | 131 | 185 | 345 | 535 | 936 | 1544 | 952 | 1554 |

| 35 | 524/868 | 668/1113 | 5.0/3.2 | 251 | 0.35 | 2.6 | 0.4 | 122 | 178 | 327 | 524 | 679 | 1121 | 695 | 1131 |

| 50 | 387/641 | 494/822 | 6.8/4.4 | 281 | 0.39 | 2.6 | 0.4 | 116 | 172 | 313 | 514 | 511 | 834 | 527 | 844 |

| 70 | 268/443 | 343/568 | 9.8/6.3 | 341 | 0.45 | 2.6 | 0.5 | 110 | 165 | 300 | 495 | 364 | 583 | 386 | 597 |

| 95 | 193/320 | 248/410 | 13.3/8.5 | 397 | 0.5 | 2.6 | 0.5 | 104 | 160 | 287 | 485 | 272 | 427 | 300 | 446 |

| 120 | 153/253 | 196/325 | 17.2/11.0 | 430 | 0.55 | 2.6 | 0.6 | 104 | 159 | 283 | 480 | 225 | 345 | 257 | 367 |

| 150 | 124/206 | 159/266 | 21.2/13.5 | 464 | 0.59 | 4.3 | 0.6 | 100 | 156 | 280 | 475 | 193 | 287 | 229 | 313 |

| 185 | 99.1/164 | 128/211 | 26.6/17.0 | 513 | 0.65 | 4.3 | 0.7 | 98 | 154 | 274 | 465 | 165 | 237 | 206 | 267 |

| 240 | 75.4/125 | 98/161 | 34.9/22.3 | 573 | 0.7 | 4.3 | 0.9 | 94 | 150 | 267 | 459 | 140 | 191 | 185 | 226 |

| 300 | 60.1/100 | 80/130 | 43.8/28.0 | 652 | 0.72 | 4.3 | 1 | 91 | 147 | 260 | 455 | 128 | 163 | 174 | 203 |

| 400 | 47.0/77.8 | 64/102 | 57.3/36.6 | 727 | 0.75 | 5.8 | 1.1 | 90 | 147 | 253 | 445 | 113 | 141 | 164 | 184 |

| 500 | 36.6/60.5 | 51/81 | 72.3/46.2 | 754 | 0.79 | 5.8 | 1.2 | 89 | 145 | 248 | 435 | 105 | 124 | 158 | 171 |

| 630 | 28.3/46.9 | 42/64 | 91.2/58.3 | 786 | 0.87 | 5.8 | 1.3 | 86 | 143 | 245 | 425 | 97 | 110 | 151 | 160 |

| 800 | 22.1/36.7 | 35/55 | 114.4/75.0 | 846 | 0.91 | 8.2 | 1.4 | 85 | 142 | 243 | 415 | 92 | 101 | 147 | 153 |

| 1000 | 17.6/29.1 | 30/46 | 143.0/94.0 | 916 | 0.99 | 8.2 | 1.5 | 83 | 141 | 239 | 405 | 88 | 95 | 144 | 148 |

Jiangsu Jinling Special cable Co., Ltd. Was founded in 1998. It is a comprehensive cable enterprise integrating research, development, production, sales and service. The company is located in nanjing, jiangsu province, the industrial concentration area, with convenient transportation. The registered trademark of the company is "Yong Heng", which covers an area of 30000 square meters, with a building area of 80, 000 square meters and annual production capacity of USD 190 million. The company has 159 employees, including 48 professional and technical talents.

The company is a high-tech manufacturing enterprise with high technical content, complete quality management system and advanced inspection methods. The company has the domestic first-class production line and testing equipment, the technical force is strong. Main products are: Medium and low Voltage power cables, control cables, instrument cables, Aluminum Alloy cable, bare conductor, Aerial bundled cable, electrical wire, compensation cable, high temperature resistant cable, fire resistant cable, fire retardant cable, wind cable, Marine cable, anti-corrosion, waterproof cable., are widely used in electric power, metallurgy, petroleum, chemical industry, automobile, papermaking, coal mine, shipbuilding, ports, lifting, building materials, pharmaceutical and other industries. Company strictly according to GB, IEC, CE, As, UL, VDS standards, and pass ISO9001 certification, to provide customers with a variety of specifications of wire and cable.

Excellent quality, perfect management and first-class service is our permanent puisuit.

More >

Other Products with This Manufacturers