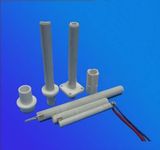

12V Mini Mch Ceramic Heating Element for Car Oxygen Lambada Sensor

| Price: |

US $ 10/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

10/Piece |

| Pay Type: |

T/T,Western Union |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Heating Type: |

Resistance Heater |

| Dimension(L*W*H): |

Accordingly |

| Weight: |

5g |

| Working Voltage: |

12V |

| Power(W): |

5W-40W |

| Power Source: |

Electric |

| Temperature: |

: Can Be Higher Than 500°c |

| Delivery Time: |

1-30 Days |

| Principle: |

Mixing Heat Exchanger |

| Structure Material: |

Ceramic |

| Application: |

Vaporizer, Ceramic Heater |

| Ceramic Heating Equipment Type: |

Ceramic Heater |

| Mixing Heat Exchanger Type: |

Hybrid Condenser |

| Recuperative Heat Exchanger Type: |

Tube Type Heat Exchanger |

| Heat Transfer Surface: |

Tubular Heat Exchanger |

| Style: |

Tube |

Product Description

Our Servies: Ceramic Heaters can be customized, we can produce and make sample according drawings, samples and technical parameters ect.

Specifitions Mini MCH ceramic heating elements for Car Oxygen Lambada sensor

1.Ceramic Heating Element

2. Voltage: 12V

3.Power:5W-40W

3. Heating up quickly

4.Meet Rohs requirement

| 1 | Part No. | O-1 |

| 2 | Usage | ceramic heater for soldering machine |

| 3 | Working Voltage | 12V |

| 4 | Resistance | Accordingly |

| 5 | Dimension of product | Accordingly |

| 6 | Electrode | Welding nickel wire or gold-plating on the electrode |

| 7 | Advantages | (1)Long lifetime: airproof structure ; the condition of deformation .can't exit

(2)Temperature rise quickly

(3)Excellent insulation

(4)Energy efficient and thermal conductivitysuper-heating simultaneously both from inside and outside

(5)Small and compact

(6)Equalized heat distribution and high power density.

(7)Meet RoHS requirement

(8)High cost performance. |

Company Information We produce every kind of super quality ceramic heating elements with the

advantages of long service time, fast heating rate, energy-efficient and eco-friendly.

SpecificationsHeat resistance steatite ceramic heaters

-Heat resistance

-Thermal insulator

-Electrical insulation performance

Heat resistance steatite ceramic heaters

Applications:Heating element holders

Stand off Insulators

Interlocking Insulating Beads&Pins

Lamp bases and caps

Thermostat part

Feature:1. High resistivity

2. Moderate strength

3. Excellent electrical properties

4. Poor heat conductivity (Thermal insulator).

5. Good resistance to thermal shock.

6. Low coefficient of thermal expansion

7. Good mechanical stability.

Fujian Yifeng Industry Co., Ltd committed to providing cost-effective heat transfer printing and heat transfer products. These are used on fabric, garment and mark heat transfer design. Our heat transfer products are available with flocking heat transfers, reflective, foil papers, rhinestones and stud. Custom heat transfers and wholesale heat transfers are welcome.

With years of experience in the line of manufacturing Heat Transfers like T Shirt Heat Transfer, Heat Printing Transfer, Heat Press Transfer, Heat Transfer Paper, Heat Transfer Design, Digital Heat Transfer, Custom Heat Transfer, Foil Transfer, Printed Heat Transfer, Rhinestone Heat Transfer, Label Thermal Transfer, Hot Stamping Foil, Reflective Heat Transfer, Flock Transfer, Iron On Heat Transfer, Numerical Heat Transfer, Heat Transfer Equipment, Heat Transfer Machine, etc., we have established ourselves as one of Taiwan's leading brands. Our sincerity and hard work has helped us to match our quality with international standards. We produce best quality Heat Transfer Products to meet the needs of our valued customers.

Heat Transfer is a new printing technology. The printing process is divided into two major processing parts: Transfer film printing and transfer printing process. Transfer film printing pre-printed the patterns on to the film surface, with rich printed pattern layers, colorful, ever-changing color difference is small, good reproducibility, and can achieve the effect of those requirements of the patterns designers, and is suitable for mass production. Transfer printing process is through one-time processing of a heat transfer machine (heat and pressure), will transfer fine pattern of transfer membrane on to the surface of product, after forming the ink layer and the surface of the product melting into one, distinctly pretty, greatly improving product quality. Moreover, they are made of extremely high quality material, which have enhanced resistance to high temperatures. We use excellent quality imported transfer paper and ink, print out very thin layer of patterns, which is breathable, non-sticky, does not crack, and does not wash off. Therefore, they remain intact and stuck to the surface even during the harshest of weather or artificial conditions. Our Heat Transfer range is valued for their high clarity printing, water-resistance, tear-resistance, strong adhesiveness, heat-resistance and high durability. Pattern printed on the merchandise will not produce colloid, if transfer to the clothes, the ink is directly sublimated into the fabric, the fabric dyed solid degree is very well and the color is sharp, so can apply to more colorful patterns. It avoids damage problems to leather, cloth, cotton and other organic material. It caters to the diverse needs of the market, and is better able to provide users with more comprehensive production services.

More >

Other Products with This Manufacturers