| Prod Model: |

BIC-1138-REV2 |

| Type: |

Rigid Circuit Board |

| Dielectric: |

FR-4 |

| Material: |

Fiberglass Epoxy |

| Flame Retardant Properties: |

V0 |

| Processing Technology: |

HASL |

| Base Material: |

Copper Clad Laminate |

| Brand: |

Bicheng |

Product Description

Multilayer PCB Board ITEQ FR-4 Base material Tg135 HASL 361

Commodity Introduction

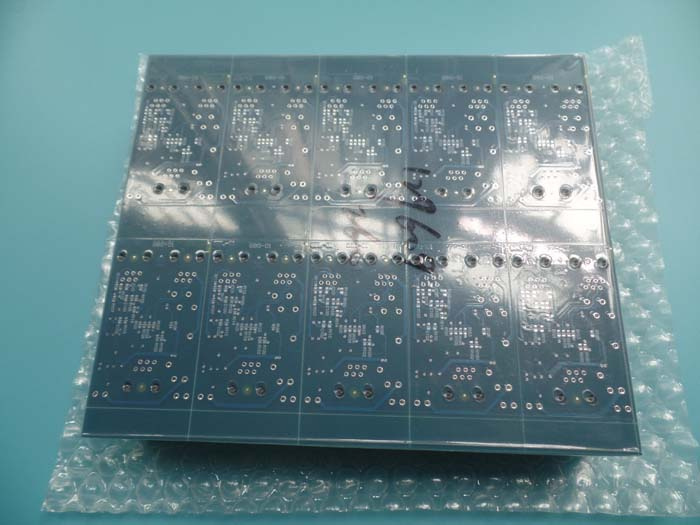

Commodity IntroductionThis is a type of 4 layer PCB for the application of Digital Electronics at 1.6mm thick with HASL Lead Free pad finish. The base laminate is from ITEQ, Solder mask and silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied Gerber data. Each 20 panel boards are packed separately.

Parameter & Data Sheet

Parameter & Data Sheet| Number of Layers | 4 |

| Board Type | Multilayer board |

| Board Thickness | 1.6mm +/-0.16 |

| Board Material | FR-4 |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 135ºC |

| |

| PTH Cu thickness | ≥20 um (See hole wall details) |

| Inner Iayer Cu thicknes | 17 um(0.5oz) |

| Surface Cu thickness | 35 um (1oz) |

| |

| Solder Mask Type and Model No. | LPSM, KSM-6189BLM1 |

| Solder Mask Supplier | KUANGSHUN |

| Solder Mask Colour | Matt blue |

| Number of Solder Masks | 2 |

| Thickness of Solder Mask | 14 um |

| |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | Whie |

| Number of Silkscreen | 2 |

| |

| Mininum Trace (mil) | 9.5 mil |

| Minimum Gap(mil) | 6.5 mil |

| |

| Surface Finish | HASL Lead free |

| RoHS Required | Yes |

| Warpage | 0.41% |

| |

| Thermal Shock Test | Pass, 288±5ºC,10 seconds, 3 cycles. No delamination, no blistering. |

| Solderablity Test | Pass, 255±5ºC,5 seconds Wetting Area Least 95% |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6012C Class 2 |

Microsection Hole Wall (um) | Hole Wall Cu Thickness | ≥20 um | Hole Wall Cu Roughness | ≤25.4 um |

| NO. | A | B | C | D | E | F | AVE |

| 1 | 24.848 | 23.648 | 23.708 | 25.348 | 24.628 | 24.258 | 24.406 |

| 2 | 24.620 | 23.442 | 23.480 | 25.120 | 24.400 | 24.030 | 24.182 |

| 3 | 24.482 | 23.282 | 23.342 | 24.982 | 24.262 | 23.892 | 24.040 |

Outline dimension Unit: mm | NO. | Required Dimension (toerance) | Actual dimension |

| 1 | 189.99 | ±0.15 | 190.06 | 190.06 | 189.97 | 190.11 |

| 2 | 160.00 | ±0.15 | 159.91 | 160.11 | 160.12 | 160.07 |

Hole Size and Slot Dimension (mm)| NO. | Requerment Dimension (tolerance) | PTH/NPT | Actual dimension |

| 1 | 0.900 | ±0.075 | Y | 0.900 | 0.875 | 0.925 | 0.900 |

| 2 | 1.200 | ±0.075 | Y | 1.200 | 1.175 | 1.220 | 1.200 |

| 3 | 3.200 | ±0.075 | Y | 3.200 | 3.175 | 3.225 | 3.200 |

Design For Manufacturability ( 2)This manufacturability guide provides an overview of various areas that printed circuit board designer may take into consideration on the fabrication possibility, manufacturing cost and reliability of their products. This DFM is divided into 5 parts for our readers. This is the section II.

Design For Manufacturability ( 2)This manufacturability guide provides an overview of various areas that printed circuit board designer may take into consideration on the fabrication possibility, manufacturing cost and reliability of their products. This DFM is divided into 5 parts for our readers. This is the section II.| Serial NO. | Procedure | Item | Manufacturing capability |

| Large volume (S<100 m²) | Middle volume (S<10 m²) | Prototype(S<1m²) |

|

| 14 | Laminating | Tolerance of laminate thickness | ±10% PCB thick | ±10% PCB thick | ±8% PCB thick |

| 15 | Maximum laminate thickness | 4.0mm | 6.0mm | 7.0mm |

| 16 | Laminate alignment accuracy | ≤±5 mil | ≤±4 mil | ≤±4 mil |

| 17 | Drill (18um, 35um, 70um etc are finished copper. If not mentioned copper, finished 1oz is the default value ) | Min.drill bit diameter | 0.2 mm | 0.2 mm | 0.2 mm |

| 18 | Min.slot router diameter | 0.60 mm | 0.60 mm | 0.60 mm |

| 19 | Min.tolerance of PTH slots | ±0.15mm | ±0.15mm | ±0.1mm |

| 20 | Max.aspect ratio | 1:08 | 1:12 | 1:12 |

| 21 | Hole tolerance | ±3mil | ±3mil | ±3mil |

| 22 | Space of via to via | 6mil(same net),12mil(different net) | 6mil(same net),14mil(different net) | 4mil(same net),12mil(different net) |

| 23 | Space of component hole to component hole | 12mil(same net),16mil(different net) | 12mil(same net),16mil(different net) | 10mil(same net),14mil(different net) |

| 24 | Etching | Min.width of etching logo | 10mil(18um),12 mil (35um),12 mil(70um) | 8mil(18um),10mil(35um),12 mil(70um) | 6mil(18um),8 mil(35um),12mil(70um) |

| 25 | Etch factor | 1.6-2.2 | 1.6-2.2 | 1.6-2.2 |

| 26 | Outer layer(18um, 35um, 70um etc are finished copper. If not mentioned copper, finished 1oz is the default value ) | Min.via pad diameter | 20mil | 16mil | 16mil |

| 27 | Min.BGA pad diameter | 12mil | 12mil | 10mil |

| 28 | Min.track and spacing | 5/5mil(18um) | 4/4mil(18um) | 3/3.5mil(18um) |

| 5/5mil(35um) | 4/4mil(35um) | 3/4mil(35um) |

| 7/9mil(70um) | 6/8mil(70um) | 6/7mil(70um) |

| 9/11mil(105um) | 8/10mil(105um) | 8/9mil(105um) |

| 13/13mil(140um) | 12/12mil(140um) | 12/11mil(140um) |

| 29 | Minimum grid | 10/10mil(35um) | 8/8mil(35um) | 4/8mil(35um) |

| 30 | Min.space (conductor to pad, pad to pad) | 6mil(18um) | 5mil(18um) | 4mil(18um) |

| 6mil(35um) | 5mil(35um) | 4mil(35um) |

| 9mil(70um) | 8mil(70um) | 7mil(70um) |

| 11mil(105um) | 10mil(105um) | 9mil(105um) |

| 13mil(140um) | 12mil(140um) | 11mil(140um) |

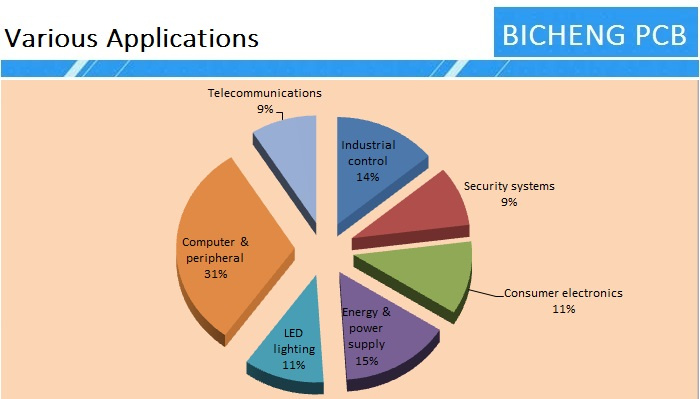

Founded in 2003, Bicheng Enterprise Limited is a professional PCB export enterprise. We have established a good relationship of cooperation with well-known enterprises in the same industry.

The factories have been ISO 9001-2008, ISO 14001-2004 and ISO/TS16949-2009 quality management system certified. Over the past 14 years, we have provided professional circuit board manufacturing solutions for more than 5000 companies worldwide.

Different plant scale to suit for your requirements

16000 square meter factory building

30000 square meter month capability

8000 types of PCB per month

ISO9001, ISO14001, TS16949, UL Certified

We have our own advantages to help you saving cost and time spent on PCB, booster your new products go to market quickly.

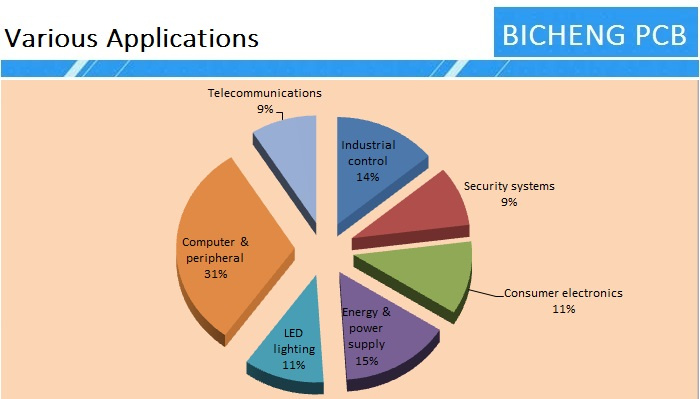

A) Various kinds of PCB products

Double sided PCB

Multilayer PCB up to 32 layers

FR-4 PCB (Tg130, Tg170)

High frequency PCB (RO4350B, RO4003C)

Aluminum PCB (1W/MK, 2W/MK, 3W/MK)

Flexible PCB

HDI PCB Board

B) Multiple PCB technology to meet the market demands

Blind via PCB, Via in pad PCB, Fine pitch BGA PCB

Impedance controlled PCB

Heavy copper PCB

Hybrid material PCB

C) Many discount policies for new customers

SMT stencil foil, free of charge

Prototype shipping cost, free of charge

Prototype test, free of charge

PCB panelization, free of charge

D) High quality PCB services

Engineering design prevents problems from occurring in pre-production.

Meet your PCB needs from prototype to mass volume production.

Eligible products rate of first production: >95%

Delivery on time: >98%, door to door shipment service

Customer complaint rate: <1%

Choose BichengPCB means you choose hassle free.