| Prod Model: |

N/M |

| Color: |

White |

| Product Name: |

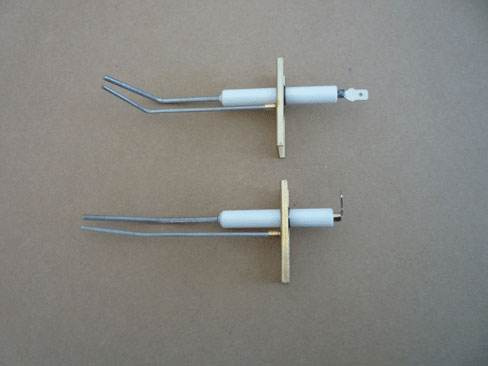

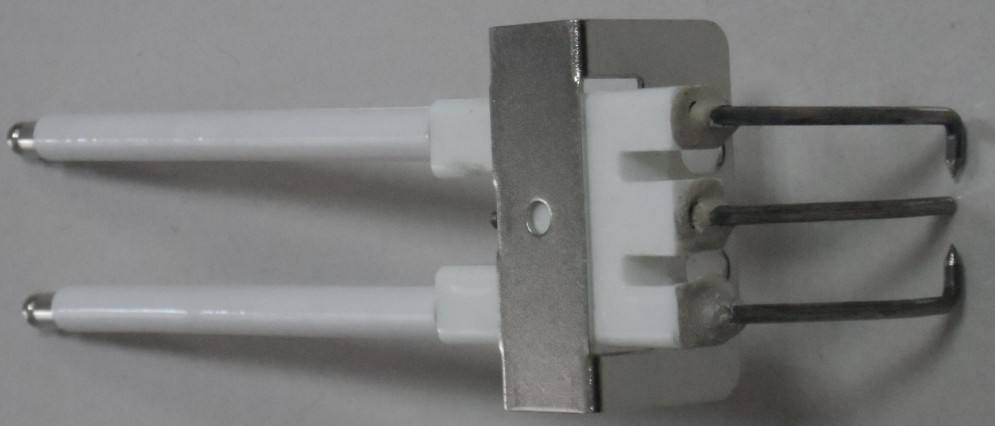

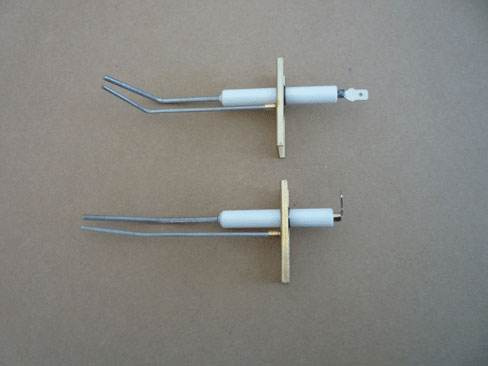

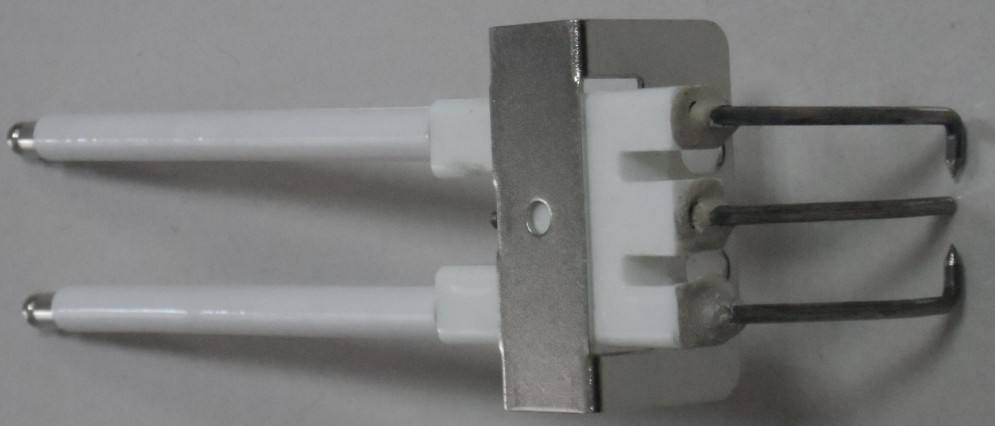

Ceramic Igniter |

| Features: |

Good Electrical Insulation |

| Advantages: |

Resistance to Electric Breakdown |

Product Description

Ceramic Igniter/ignitorA long-time expert in the field of ceramic igniters, we provide reliable and long-life ceramic igniters in hot surface ignition (HSI) systems and ceramic spark igniters. Ceramic Insulator Body: 95% Alumina, Steatite with glazed or no glazed layer, electrode Pin/Rod: OCr25Al5, OCR25, OCR27, SUS304, Ni80Cr20, KanthalA1, etc, cable: UL1332, UL1911, UL3573, UL3071, UL3239 etc, bare copper wire;teflon wire;silicon rubber wire;VDE wire,etc. Ceramic Igniter for Wood Pellet Boilerwith the advantages of long service time, fast heating rate, energy-efficient and eco-friendly.

Characteristic

1.High temperature-resistance Ceramic Igniter for Wood Pellet Boiler which can reach a permanent working temperature above 950°C +/-

2.Energy saving, super fast heating-up

3.Air can through and around inside and outside of the heater.

Heat can be transfered from both inside and ouside of the heating element.

4.Electrically oxidation and corrosion-resistant

5.High load-bearing capacity(thermal shock resistance, cycles)

6.Customization the igniters according to customers' specific requirement.

Ceramic Igniter for Wood Pellet Boiler for pellet boilers need only approx 1/10 of the energy of

that needed by hot air fans and ignition blowers. Their ignition capacity

lies between 120 and 200 Watt. Depending on the positioning of the ignition element in the boiler,

the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions!

Igniting wood chips, firewood, coal bricks or other biomass (such as corn, etc.) is possible.

| Material | Unit | Steatite | 95% Alumina | 99.5% Alumina |

| Density | G/cm3 | 2.7 | 3.65 | 3.85 |

| Highest application temperature | C | 1100 | 1500 | 1800 |

| Bending strength | Mpa | 150 | 300 | 340 |

| Compressive strength | Mpa | 900 | 3400 | 3600 |

| Hardness | HV0.5 | 800 | 1800 | 2000 |

| Insulation breakdown strength | KV/mm | 10 | 15-18 | 18 |

| Processing technology |

| Process range (mm) |

| Outside Diameter | 1---300 |

| Inside Diameter | 0.5---300 |

| Length | 0.5---1200 |

| Accuracy of working (mm) |

| Perpendicularity | 0.01 |

| Concentricity | 0.01 |

| Roundness | 0.005 |

| Straightness | 0.005 |

| Parallelism | 0.01 |

| Planeness | 0.005 |

| Roughness | 0.05 |

| Fit clearance | 0.005 |

Applications One special application area for high temperature ceramic heater element for

biomass boiler heating systems is in heating systems that use solid fuels such as wood pellets

as energy source. The challenge here is to ignite the biomass in a very short time while retaining

very low emission values.

Jiangsu Xindelong Precision Ceramics Co., Ltd. is located in Yixing Economic Development Zone, which is famous for China all over the world, the company name of Yixing Tigar Precision Ceramic Co., Ltd is our subsidiary.

Xindelong Ceramics has dedicated in manufacturing and processing precision parts/components with a wide range of products and services covering high precision ceramics and high performance ceramics, such as machinery ceramic parts/components, textile ceramic parts, electronic ceramics parts, engineered ceramic components, pump components, valve components, flow components, wear components, corrosion resistant ceramic parts, high temperature ceramic parts, welding ceramic parts, ceramic parts for semiconductor etc. The raw materials is including alumina, zirconia, silicon carbide, silicon nitride, mullite, cordierite and steatite, PBN/ALN, BeO and graphite and so on.

Xindelong Ceramics has complete facilities, such as CNC machines, internal grinding machines, cylindrical grinding machines, centerless grinding machines, double surfacce lapping machines, vibration polishing machines, honing machines, and electron microscope, three-coordinates measuring machine, hardness tester, surface roughness instrument-to enable us to manufacture technical ceramic components to the highest specifications.

Our current customers comes from USA, Canada, Germany, England, Italy, Spain, Denmark, Mexico, Brazil, Argentina, Korea, Singapore, Thailand, Malaysia and so on.

Our company always insists on quality first, the supremacy of the purposes of the users. We'd like to cooperate sincerely with enterprises at home and abroad to create a win-win future.