| Prod Model: |

Flexible Ceramic Pad Heater |

| Product: |

Ceramic Heater Pad |

| Size: |

Customized |

| Max Temperature: |

1050 Degree Celsius |

| Resistance Voltage: |

2000V/Min |

| Insulation: |

5 Mohm |

| Radiating Temperature Inhomogeneity: |

More Than 5% |

| Compression Strength: |

2000 MPa |

| Use Life: |

3000hours |

| Thermal Conductivity: |

24 W/Mk |

| Application: |

Heater |

Product Description

FCP Flexible Ceramic Pad Heater1. IntroductionHongtai's high quality ceramic heating elements is manufactured from high grade nickel-chrome (Ni-Cr) 80/20 resistance wire and high purity (95%) aluminum oxide ceramics beads. These nickel-chrome wires have much more durable lifetime than normal alloy heating wires. These Alumina beads have high temperature resistance, excellent insulating property, and efficient thermal conductivity, which provides FCP heaters with exceptional electrical insulating,and thermal shock resistance and thermal conductivity qualities..

The insulators together with the resistance wires are very flexible and gives a good heat radiation and effective heat transmission during the required thermal process. Hongtai FCP heating elements are manufactured with a wide range of voltages, ranging from 30 volts to 255 volts. The standard heaters are suitable for heat treatment temperatures up to 1000°C.

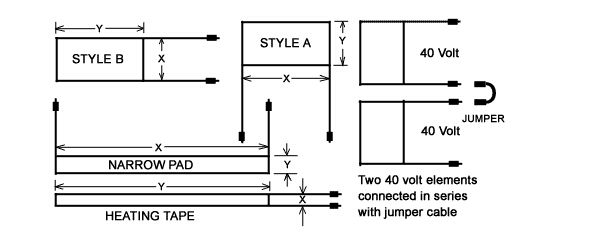

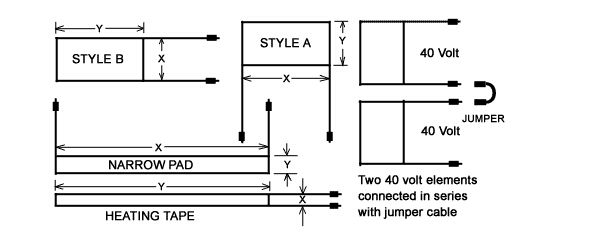

They are designed for repeated heating applications. Their modular design permits a variety of element shapes, sizes, and thermal capacities to choose from. They can be used bare (as supplied) or with the application of rigid or flexible insulation to retain heat and speed up the heat treating jobs.2. Characteristics & Properties for Flexible Ceramic Pad Heater| Voltage (V) | 60/80 |

| Current (A) | 45 |

| Power (kw) | 2.7/3.6 |

| Maximum Use Temperature*, °C (°F) | 1121 (2050) |

| Heating Element Type | Ni-Cr |

| Lead Length (in.) | ~24 |

| Insulator Type | Aluminum Oxide |

| Insulator Color | Pink |

3. Main Features of Flexible Ceramic Pad Heater1) It can be contacted with the workpiece heated, bending, folding, combustion.

2) it can be used for all kinds of metal components, pipeline, large container preheating before welding, intermediate consumption of hydrogen and welding property Bureau Ministry of heat treatment.

3) Fast heating speed, high heat utilization rate, obvious energy saving, low labor intensity, reliable safe use, convenient operation of the excellent performance.

4) One of the most innovative and practical local heat treatment heater in the welding field. Maximum working temperature 1050.

4. Suggested Application of Flexible Ceramic Pad HeaterHeating source in furnaces and industrial process equipment operating to 1121ºC (2050ºF).

4. Suggested Application of Flexible Ceramic Pad HeaterHeating source in furnaces and industrial process equipment operating to 1121ºC (2050ºF).

Post heat treatment of weld joints.

Preheating of materials to be welded. 5. Availability for Reference60V Series

5. Availability for Reference60V Series

Type Voltage

|

Width (mm)

|

Length (mm)

|

Rating (kW)

|

Current (amp)

|

| CP3-60V | 75 | 724 | 2.7 | 45 |

| CP4-60V | 102 | 533 | 2.7 | 45 |

| CP6-60V | 152 | 368 | 2.7 | 45 |

| CP8-60V | 203 | 267 | 2.7 | 45 |

| CP10-60V | 254 | 229 | 2.7 | 45 |

| CP12-60V | 305 | 184 | 2.7 | 45 |

| CP15-60V | 380 | 146 | 2.7 | 45 |

| CP18-60V | 457 | 127 | 2.7 | 45 |

| CP21-60V | 535 | 102 | 2.7 | 45 |

| CP24-60V | 610 | 83 | 2.7 | 45 |

CP26-60V | 740 | 83 | 2.7 | 45 |

80V SeriesType Voltage | Width (mm) | Length (mm) | Rating (kW) | Current (amp) |

CP3-80V | 991 | 991 | 3.6 | 45 |

CP4-80V | 102 | 737 | 3.6 | 45 |

CP6-80V | 152 | 501 | 3.6 | 45 |

CP8-80V | 203 | 368 | 3.6 | 45 |

CP10-80V | 254 | 368 | 3.6 | 45 |

CP12-80V | 305 | 248 | 3.6 | 45 |

CP15-80V | 380 | 203 | 3.6 | 45 |

CP18-80V | 457 | 165 | 3.6 | 45 |

CP21-80V | 535 | 145 | 3.6 | 45 |

CP24-80V | 610 | 125 | 3.6 | 45 |

CP33-80V | 740 | 100 | 3.6 | 45 |

CP33-80V | 840 | 85 | 3.6 | 45 |

CP36-80V | 915 | 80 | 3.6 | 45 |

We are able to meet our customers' needs regarding special models of size, shape, voltages and power rating. If you feel interested in our FCP heaters, please kindly contact us.

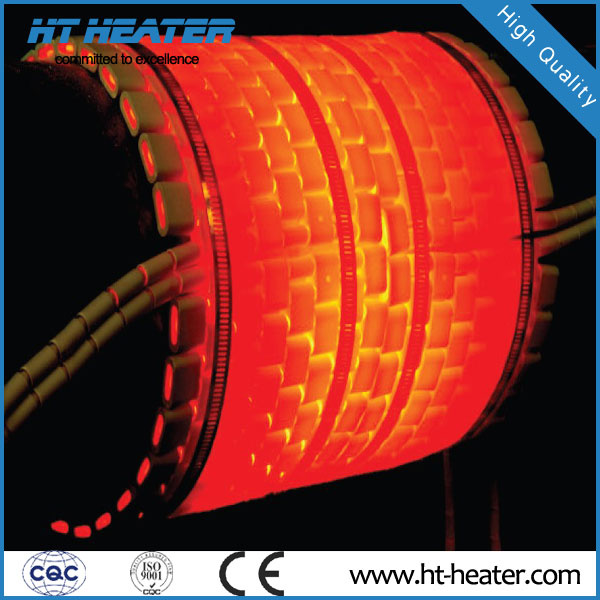

6. Show of Flexible Ceramic Pad Heater

7. Contact Information

Please kindly contact us, if you are interested in our products.

Better service, price, delivery time we will assit you. Thanks a lot in advance!

Founded in 2008, Yancheng Hongtai Alloy Electric Apparatus Co., Ltd is a professional Heating element manufacturer. We are Branch of Yancheng Songtai Electric Heating Element Factory(founded in 1990).

With product development, machine improved and technological innovation, we have improved OEM capacity and also have our own brand Hongtai. We have focused on management and quality control according to ISO 9001 standard. We produce top quality heaters and offer efficient service to meet customer's requirements.

We have 10 engineer with more than 10 years of experience in heating element filed to design and develop new heating elements for clients and provide professional suggestion for clients.

We introduce professional machines from Taiwan, Japan and Germany to support our production, including automatic powder filling machine, polishing machine, shrink tube machine, punching machine, automatic reeling machine and so on.

Our main products are Rod heaters, band heater, infrared heaters, temperature sensors and various heating alloys. Our products have got CE, RoHS certification.

Our factory complies with China's Labor Law to treat our workers - no force over-time working and working on legal holiday and no child labor. All workers have 2-day holiday on weekends. If there is any overtime working for urgent shipment, we will pay salary to them based on China's Labor Law.

We welcome you to cooperate with us based on win-win situations. Please feel free to contact us for further information