| Prod Model: |

MDM291 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Fully Welded: |

Wet |

| Output: |

Analog Sensor |

| Usage: |

Processing Pressure Measurement |

| Theory: |

Pizoresistive |

| Pressure Range: |

0~35kpa^2MPa |

| Max Static Pressure: |

20MPa |

| Response Time(10% ~ 90%): |

< 1ms |

| Wide Temperature Compensation: |

0~70 Celsius |

| Power Supply: |

<= 2.0madc |

| Insulation Resistor: |

100m Omega, 100VDC |

Product Description

FulI Welded Differential Pressure Sensor MDM291

Features:

·Pressure range: 0~35kPa2MPa

·Constant Current Power Supply

·No O-rings, all welding construction, possible for various media

·Stainless steel 316L

·High static pressure 20MPa

·Wide temperature compensation: 0ºC~70ºC

·Different threads connection optional

Application:·

·Industrial process control

·differential pressure measure

·gas, liquid pressure measure

·Pressure checking meter

·Pressure calibrator

·Ventura and eddy-current flow meter

Introduction: MDM291 piezoresistive differential pressure transducer is an OEM differential pressure

measure element using stainless steel isolated diaphragm, all welding construction and

having no O_rings. It has unified construction, higher static pressure, good stability and reliability. The high and low pressure sides are both protected by isolated diaphragm and welded with male screw thread pressure port, therefore the two pressure sidesStable and Precise Pressure Transmitter are both possible to corrosive and conductive liquid media.

The measured pressure is transmitted onto the die through isolated diaphragm and filling silicon oil. The sensor element choose high accuracy and high stability silicon die. It achieves precise differential pressure measurement. The transducer is produced in advanced production line, through automatic computer testing and temperature compensation, so it has good temperature feature. It can be widely used in industrial process control field etc. for differential pressure measurement.

Electric Performance:

Power supply: ≤2.0mADC

Electric connection: 100mm silicon rubber flexible wire

Common Mode Voltage Output: 50% input (typ.)

Input impedance: 2kΩ~8kΩ

Output impedance: 3.5kΩ~6kΩ

Response Time(10% ~ 90%): < 1ms

Insulation Resistor:100MΩ,100VDC

Overpressure: refer to Order Guide

Max static pressure: 20MPa

Zero drift/ Static pressure: ≤0.5mV/MPa

Construction Specification:

Diaphragm material: stainless steel 316L

Housing: stainless steel 316L

Leading wire: silicon rubber flexible wire

Net weight: 355g

Environment Condition:

Position Effect: deviate 90°from any orientation, zero change ≤0.2%FS

Shock: No change at 10gRMS,(20~2000) Hz

Impact: 100g, 10ms

Media Compatibility: gas or liquid that is compatible with stainless steel

Basic Condition:

Media temperature: (35±1)ºC

Environment temperature: (35±1)ºC

Shock: 0.1g(1m/s/s) Max

Humidity: (50%±10%) RH

Local Air Pressure: (86~106) kPa

Power supply: (1.5±0.0015) mADC

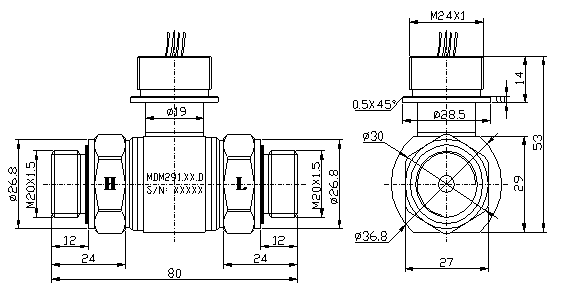

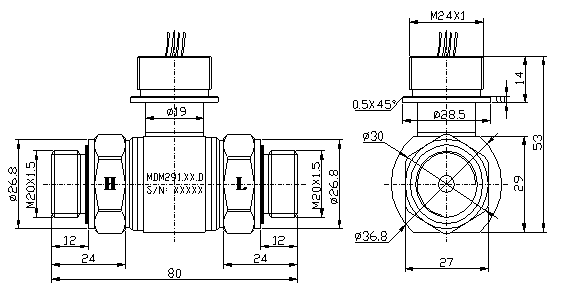

Outline Construction:

(Unit:mm)

Order Guide:

| MDM291 | Piezoresistive OEM Differential Pressure Sensor |

| | | Range Code | Pressure range | Positive Overpressure | Negative Overpressure |

| 0A | 0~35kPa | 70kPa | 35kPa |

| 02 | 0~70kPa | 150kPa | 70kPa |

| 03 | 0~100kPa | 200kPa | 100kPa |

| 07 | 0~200kPa | 400kPa | 200kPa |

| 08 | 0~350kPa | 700kPa | 350kPa |

| 09 | 0~700kPa | 1400kPa | 700kPa |

| 10 | 0~1MPa | 2.0MPa | 1.0MPa |

| 12 | 0~2MPa | 4.0MPa | 1.0MPa |

| | | Code | Temperature Compensation Mode |

| L | Laser Trimming |

| | M | Outer compensated resistor (providing resistor value) |

| | | Code | Electric Connection |

| 2 | 100mm silicon rubber flexible wires |

| | | Code | Pressure port |

| | (default) | Without pressure connection and electrical installation connection |

| | C1 | M20×1.5 male, face type seal |

| | C2 | G1/4 male |

| | C3 | G1/2 male |

| | C4 | G1/4 female |

| | |

| MDM291 12 L 2 C1 whole spec. |

Order Note:

1. High pressure side and Low pressure side are marked "H" and "L" respectively on the body;

2. During application, please pay attention that the pressure of high pressure side should be higher than that of low pressure side;

3. Please pay attention to protect the diaphragm, prevent it from damaging;

4. Please do not pull the leading wires.

Micro Sensor Co., Ltd, the leading manufacturer of piezo-resistive pressure sensors and transmitters in China, was founded by Sino-US joint venture in 1993. We are providing pressure sensing & measuring solutions to customers all over the world.

With Digital Wide-Temperature Compensation, Non-linearity Correction and Data-Collection by Bus Operation, we supply users OEM pressure sensors, pressure transmitters, level transmitters, measuring and controlling instruments, which have high quality and reliable performance in the local on-site environment.

Based on more than 20 years production experiences, Micro Sensor now have manufacturing capacity of 1.2 million pieces pressure sensors and 400 thousand pieces transmitters in one year. And we are also capable to satisfy the customized specification and designs according to clients' Specified requirements.

Quality is the life of company. Micro Sensor executes I S O 9 0 0 1 International Management System strictly to make sure every procedure qualified in our production. Furthermore, the main products for pressure sensors and transmitters, are also certificated by C E, R o H S, C B, U L and A T E X respectively for different global markets.

Micro Sensor now does business with customers more than 70 countries. More and more global friends know Micro Sensor and make win-win cooperation with us. Wherever you are, whenever you are, find Micro Sensor for any pressure sensing & measuring question. We are looking forward to supporting you with our best services!