Product Description

SMA SPECIFICATIONS

| Electrical | |

| Impedance | 50 Ohm |

| Frequency Range | |

| .141" & .085" O.D. Copper Jacket Semi-Rigid Cable | 0-6 GHz |

| Flexible Cables | 0-3 GHz |

| Voltage Rating | |

| RG-55, 58, 141, 142, 223, 303 | 500 volts peak |

| RG-122, 174, 188, 316 | 375 volts peak |

| Dielectric Withstanding Voltage (max.) | |

| .141" & RG-58 Group | 1000 VRMS |

| .085" & RG-316 Group | 750 VRMS |

| VSWR for Straight Connectors | |

| .141" O.D. Copper Jacket Cable | 1.05 + .005 f (GHz) |

| RG-55 Group | 1.15 + .011 f (GHz) |

| RG-122 Group | 1.15 + .02 f (GHz) |

| RG-178 Group | 1.20 + .025 f (GHz) |

| VSWR for Angle Connectors | |

| .141" O.D. Copper Jacket Cable | 1.10 + .01 f (GHz) |

| RG-55 Group | 1.15 + .02 f (GHz) |

| RG-122 Group | 1.15 + .03 f (GHz) |

| RG-178 Group | 1.20 + .03 f (GHz) |

| Insulation Resistance | 5000 MΩ |

| Contact Resistance | |

| Center Conductor | 2.0 mΩ |

| Body | 2.0 mΩ |

| Braid to Body | 0.5 mΩ |

| RF Leakage | -60 dB min |

| Insertion Loss | .03 sqrt(f(GHz)) dB max |

| Environmental | |

| Temperature Range | -65ºC to +165ºC |

| Thermal Shock | MIL-STD-202 Method 107 (test cond. B) except at high temp test @ + 200ºC |

| Corrosion | MIL-STD-202 Method 101 (test cond. B) 5% salt solution |

| Vibration | MIL-STD-202 Method 204 (test cond. D) |

| Shock | MIL-STD-202 Method 213 (test cond. I) No Discontinuity Permitted |

| Moisture Resistance | MIL-STD-202 Method 106, except step 7b (vibration) omitted, and high humidity measurements do not apply |

| Weatherproofing | |

| Crimp Type | heat shrink tubing |

| Solder Type | Silicone rubber gaskets |

| Altitude | MIL-STD-202 Method 105 (test cond. C), no corona at 70,000 ft |

| .141" & RG-55 Group | 250 WRMS |

| .085" & RG-122 Group | 190 VRMS |

| Mechanical | |

| Contact Captivation | All types, except as noted |

| Connector Durability | 500 mating and unmating cycles @ 12 cycles/min |

| Cable Retention | |

| RG-58, .141, 303 | Crimp type, 60 lbs min |

| RG-55, 142, 223 | 80 lbs min, 400 N.cm |

| Connector Affixment to Cable | Crimp types, solder types |

| Connector Affixment to Center Contact | Solder, except as noted |

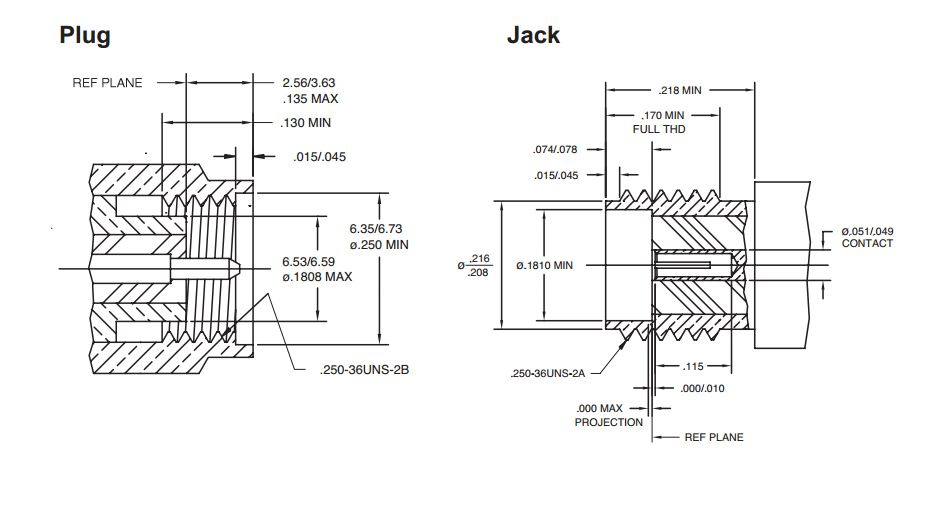

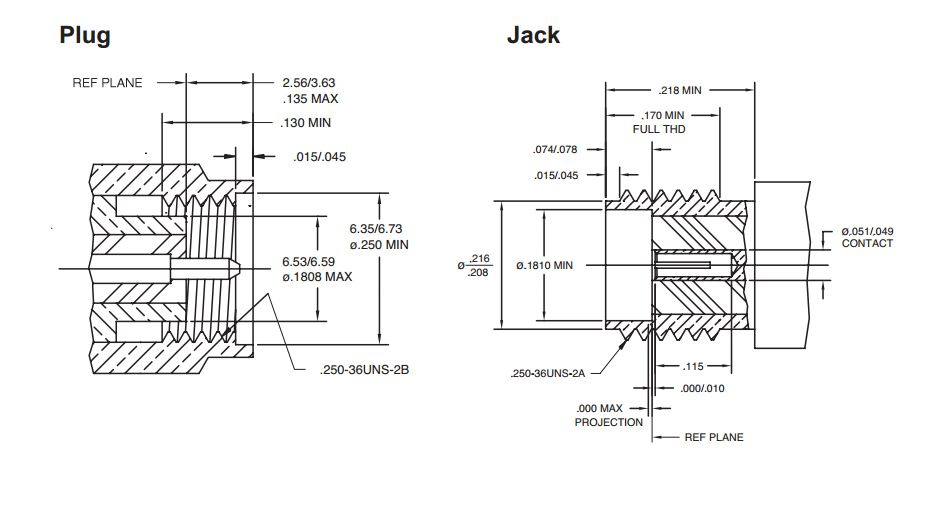

| Mating | .250-36 threaded coupling |

| Mating Torque | |

| Minimum | 2" lb, 22 N.cm |

| Recommended (Industrial/Military Grade Parts) | 7-10" Ib, 80-110 N.cm |

| Recommended (Commercial Grade Parts) | 4-6"lb, 45-67 N.cm |

| Maximum (Industrial/Military Grade only) | 15" lb, 170N.cm |

| Coupling Nut Retention | |

| Axial Force | 100lbs. Min., 300N.cm |

| Torque | 15" lb min. 76 N.cm |

| Jacks | N/A |

REVERSE POLARITY SMA SPECIFICATIONS

| Electrical | |

| Impedance | 50 Ohm |

| Frequency Range | |

| Semi-Rigid | 0-18 GHz |

| Flexible Cables | 0-12.4 GHz |

| VSWR | |

| Straight Connectors: .141" S/R | 1.05 + .005 f (GHz) |

| Straight Connectors: RG-174 | 1.20 + .025 f (GHz) |

| Dielectric Withstanding Voltage | 1000 VRMS |

| Insertion Loss | .03 sqrt(f(GHz)) dB max |

| Insulation Resistance | 5000 MΩ |

| RF Leakage | -60 dB min |

| Voltage Rating | 375 volts peak |

| Environmental | |

| Temperature Range | -65ºC to +165ºC |

| Moisture Resistant | Mil-STD-202, Method 106 (test cond. B) |

| Corrosion | Mil-STD-202, Method 101, Condition B |

| Vibration | Mil-STD-202, Method 204, Condition B |

| Mechanical | |

| Mating | .250-36 threaded coupling |

| Cable Affixment | Crimp or solder types |

| Center Conductor | Solder |

| Cable Retention | 60- 80 lb, depending on cable |

These characteristics are typical and may not apply to all connectors.

INTERFACE DIMENSIONS

Jiangsu Telaisi Electronical Equipment Co., Ltd was founded in 1995 and located in Jiangsu Province. Our factory is a professional manufacturer of R&D, producing RF connectors and cable assemblies, processing various components.

The factory independently developed products commonly used specifications of SMA\SMB\SMC\BNC\L9\MCX\MMCX\TNC\FME\RCA connectors, RG59\RG6\RG11 series connector heads and all kinds of waterproof connector. The factory has a professional R&D team, combined with years of R&D experience, can address the specific customer needs and can provide customers with professional technical support.

Our factory is not only committed to continue to build and improve the product platform but also to establish Quality Management System and Environmental Management System at the same time, and provide solid backing for the factory's sustainable and stable development. The factory passed ISO9001 quality management system certification and ISO10041 environment system certification in 2008. Our products obtained from Taiwan\Japan\Vietnam\Thailand\Europe&America and the domestic customer's recognition and praise.

Since the plant, we have taken the market as the core, taken the product as the guideline, taken technology as the foundation, taken the quality as the lifeblood. For the domestic and foreign markets, we implement brand strategy and take brand development.

Our factory has a broad market prospects. Products are widely used in CATV communication digital network\aerospace industry\satellite transmission\photoelectric transmission and other types of industrial, civil and military fields.

We sincerely welcome domestic and foreign customers to come to discuss cooperation and common development.