Laser Elastic Rubber Backlit Silicone Keypad

| Price: |

US $ 0.5/Piece |

| Trade Terms: |

FOB,CIF |

| Min Order: |

1000/Piece |

| Pay Type: |

L/C,T/T,Paypal,Money Gram,Western Union |

| Prod Model: |

9C |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Color: |

Available |

| Materials: |

Silicone Rubber |

| Work Temperature: |

-40c-130c |

| Environmental Friendly: |

Raw Material Pass RoHS, SGS Test |

| Type: |

Flexible |

| Material: |

Silicone |

| Application: |

Camera |

Product Description

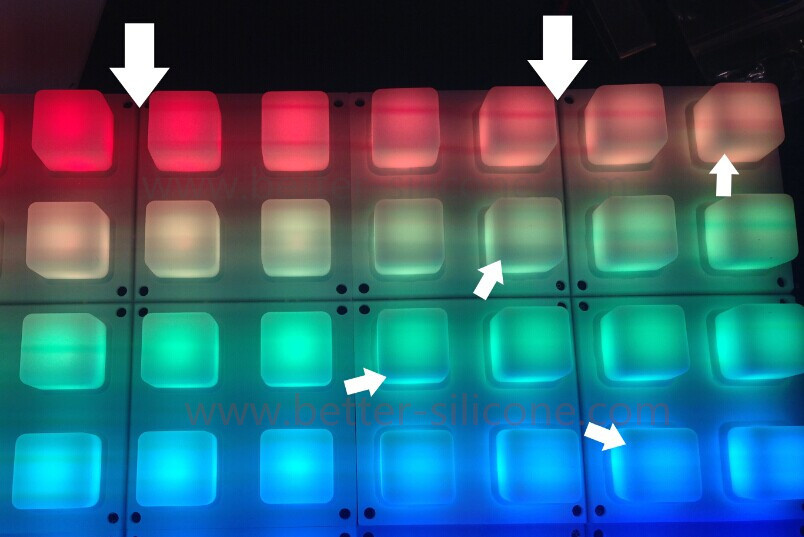

Silicone Rubber Backlight Keypad:That have some ways to process the backlight silicone keypads.1. Laser Etched Silicone Keypad.Firstly, Do Printed Ink Process, the printed ink color is same to the laser etched legends, and then spray coating on the surface the silicone rubber keypad. Lastly place the keypads on the laser etched machines for process. Notes: The legends color should have a high contrast with the spray coating colorLike following case: The legends color is white, and the spray coated color is gray.  2. Translucent Silicone Backlight Keypad 1.) Translucent Silicone Backlight Keypad take full advantage of silicone original materials which is translucent. Different silicone is different transparency. Generally, more better silicone materials, the color is more transparent. The original color of liquid silicone is almost transparent.

2. Translucent Silicone Backlight Keypad 1.) Translucent Silicone Backlight Keypad take full advantage of silicone original materials which is translucent. Different silicone is different transparency. Generally, more better silicone materials, the color is more transparent. The original color of liquid silicone is almost transparent.  2.) Silk Screen Translucent Silicone Backlid Keypad, generally, need spray painted before do font or symbol printing on the surface, and the do PU coating process to protect the legends. However, Silk Screen Translucent Silicone Backlight Keypad, which needn't do spray coating process. For better backlight legends effects, sometimes, also needn't do PU coating or UV+PU coating. Knowledge: The light source of Plastic Backlit Keyboard is different the backlight which light source behind the LCD.

2.) Silk Screen Translucent Silicone Backlid Keypad, generally, need spray painted before do font or symbol printing on the surface, and the do PU coating process to protect the legends. However, Silk Screen Translucent Silicone Backlight Keypad, which needn't do spray coating process. For better backlight legends effects, sometimes, also needn't do PU coating or UV+PU coating. Knowledge: The light source of Plastic Backlit Keyboard is different the backlight which light source behind the LCD. Silicone Rubber Keypads1. Silk Screen Silicone Keypad2. Laser Etched Silicone Keypad3. Epoxy Coating Silicone Keypad4. P+R Keypad5. Double Color Silicone Keypad6. Backlit Silicone Keypad7. Fluorescent Silicone Keypad8. Conductive Printing Silicone Keypad9. M+R Keypad Quickly Quotation Requirements1. Offer 2D, 3D design (PDF, CAD, STEP, IGS, slprt. ) drawings, or samples2. Include number of legend and silicone colors, Of need silicone light guide.3. With or without carbon pills4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc.5. Quantities to be quotedThese are the primary elements for a quotation. Other details such as travel, force, durometer and tactile response can be determined at the time of order.Specialty features such as protective coatings, laser etching, light pipes, etc. should be included. Our Advantage:1. Precision Own Mold-Making Technology (Since 1998)2. Competitive Price: Origin Manufacturer.

Silicone Rubber Keypads1. Silk Screen Silicone Keypad2. Laser Etched Silicone Keypad3. Epoxy Coating Silicone Keypad4. P+R Keypad5. Double Color Silicone Keypad6. Backlit Silicone Keypad7. Fluorescent Silicone Keypad8. Conductive Printing Silicone Keypad9. M+R Keypad Quickly Quotation Requirements1. Offer 2D, 3D design (PDF, CAD, STEP, IGS, slprt. ) drawings, or samples2. Include number of legend and silicone colors, Of need silicone light guide.3. With or without carbon pills4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc.5. Quantities to be quotedThese are the primary elements for a quotation. Other details such as travel, force, durometer and tactile response can be determined at the time of order.Specialty features such as protective coatings, laser etching, light pipes, etc. should be included. Our Advantage:1. Precision Own Mold-Making Technology (Since 1998)2. Competitive Price: Origin Manufacturer.

1.) Mold-Making Plant

2.) Silicone Rubber Compression Plant

3.) Plastic Injection Plant

4.) Liquid Silicone Rubber Injecton Plant (LSR)

5.) Assembly Plant.

3. Five Experienced Designers and Engineers

4.Production and Test strictly according to ISO9001.Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.5. Production Environment6. Rapid Reaction Organization: Support Customer at short time

Xiamen Better Silicone Import and Export Co., Ltd, which specialized in making Rubber Compression / plastic injection /Liquid Silicone Rubber Injection mold tool and producing silicone rubber compression parts, plastic injection parts, Liquid silicone rubber injection parts: Rubber Sheet, Gasket, O-RING, Seal, Silicone Rubber Valve, Silicone Rubber Keyboard, Rubber Nozzle, Rubber Grommet, Silicone Bushing Sleeves, Rubber Damper, Rubber Bumper, Rubber Bellows, Silicone / Liquid Silicone Mask, Connectors etc.

Xiamen Better Silicone Import and Export Co., Ltd have five production Plant:

1. Mold-Making Plants: Rubber Compression Mold, Plastic Injection Mold, Liquid Silicone Rubber Injection Mold

2. Rubber (Silicone) Compression Plant

3. Plastic Injection Plant

4. Liquid Silicone Injection Plant (Clear Room)

5. Assembly Plants (Clear Room)

As a factory management cooperation, we focus on improving Mold-making technology, each production plant efficiency, and take full advantage to enjoy customer's demands and meet marketing demand.

Our Advantage:

Own Precision Mold-making Technology (since 1998 years)

Experienced Technical Persons and Workers

One-stop Service: Mold Tool Making, Silicone Rubber Compression Production, Plastic Injection Production, Liquid Silicone Injection Production and Assembly.

Experienced Industry Knowledge, Leading industry: Electronic Industry (like Precision Silicone Rubber Smart Cellphone Parts, Rubber Keypad, 3M Adhesive Tape+Silicone Rubber etc), Medical Industry (like Silicone/Liquid silicone rubber mask/valve/gasket etc), Sanitary Industry (like Silicone Shower Head Nozzles).

Well-established and Down-to-earth Company: Improve production technology and also use qualified formal materials

More >

Other Products with This Manufacturers