New Design 230V Pellet Igniter for Biomass Boiler

| Price: |

Negotiable/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

100/Piece |

| Pay Type: |

L/C,T/T,Paypal,Western Union |

| Prod Model: |

G90105-01 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

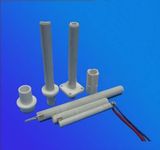

| Type.: |

Insulating Ceramic |

| Cable: |

0.5m or Accordingly |

| Place Of Origin: |

Fujian,China |

| Heating Zone: |

43mm |

| Voltage: |

230V |

| Ceramic Holder: |

17.5mm/25.00mm or Accordingly |

| Resistance: |

(40-200)Ohm |

| Standard Dimension: |

L=94mm,D=17.5mm |

| Material.: |

Alumina Ceramic |

Product Description

Characteristic

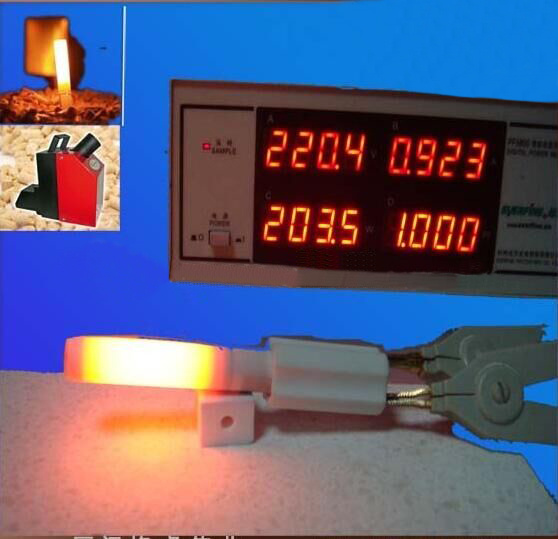

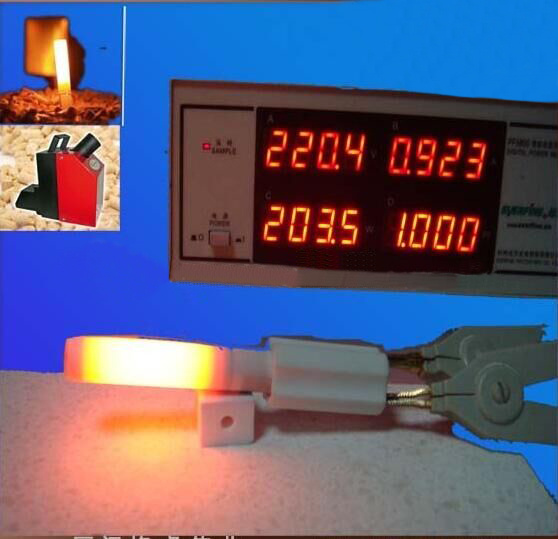

1.High temperature-resistance ceramic pellet igniter which can reach a permanent working tem-

perature above 750°C

2.Energy saving, super fast heating-up

3.Air can through and around inside and outside of the heater.

Heat can be transfered from both inside and ouside of the heating element.

4.Electrically oxidation and corrosion-resistant

5.High load-bearing capacity(thermal shock resistance, cycles)

5.Customization the igniters according to customers' specific requirement.

Application

One special application area for Green Way's high temperature pellet igniter is in heating

systems that used solid fuels such as wood pellets as energy source. The challenge here is to

ignite the biomass in a very short time while retaining very low emission values. This can be

perfectly achieved by Green Way's hot surface ceramic pellet igniter.

Ceramic hot surface pellet igniter for pellet boilers need only approx. 1/10 of the energy of that

needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 200 Watt.

Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 s

econds is extremely short. This also means minimal emissions!

Igniting wood chips, firewood, coal bricks or other biomass (such as corn, etc.) is possible. Mass customization is available.

1 | Part No. | G90105-01 |

2 | Usage | ceramic pellet igniter |

3 | Working Voltage | 230VAC |

4 | Power | 170 W |

5 | Dimension of product | Standard Dimension |

6 | Cable | 0.5m OR accordingly |

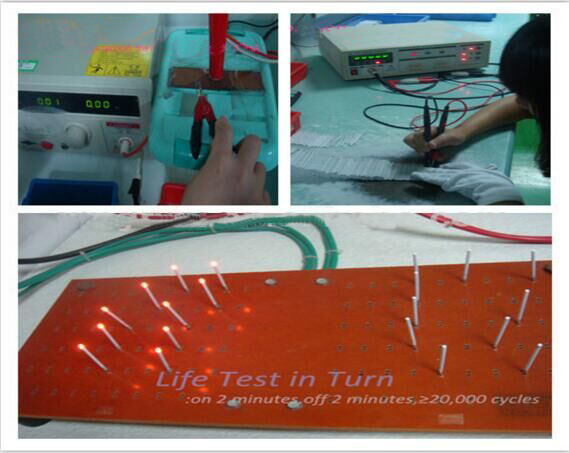

7 | Advantages | (1)Ready to fit solution: High temperature heating element in temperature-resistant ceramic socket (2)Air can flow through and around inside and outside of heater (3)Element temperature: over 1000 °C in permanent and alternating operation, for a short time up to 1200 °C (4)Lifetime up to 100,000 heating cycles, depending on operating conditions (5)Oxidation and corrosion-resistant (6)Ignition through air heating: Due to extremely high heater temperature and ideal geometric conditions, air is heated in a very short time to very high temperatures - the ideal ignition blower! (7)Igniting wood chips, firewood, coal bricks or other biomass (corn, etc.) is possible. |

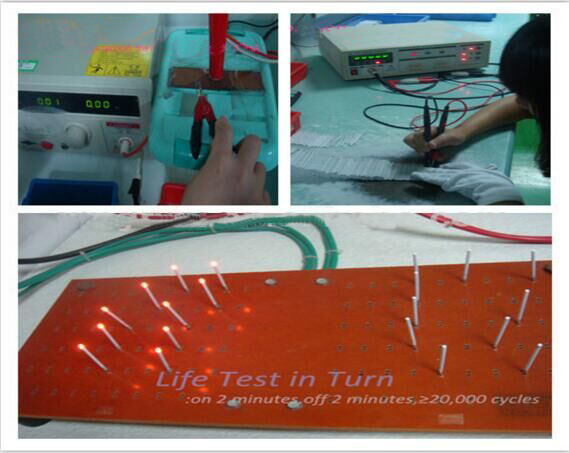

~~~Kinds of Inspection before Goods Delivery~~~

Fujian Yifeng Industry Co., Ltd committed to providing cost-effective heat transfer printing and heat transfer products. These are used on fabric, garment and mark heat transfer design. Our heat transfer products are available with flocking heat transfers, reflective, foil papers, rhinestones and stud. Custom heat transfers and wholesale heat transfers are welcome.

With years of experience in the line of manufacturing Heat Transfers like T Shirt Heat Transfer, Heat Printing Transfer, Heat Press Transfer, Heat Transfer Paper, Heat Transfer Design, Digital Heat Transfer, Custom Heat Transfer, Foil Transfer, Printed Heat Transfer, Rhinestone Heat Transfer, Label Thermal Transfer, Hot Stamping Foil, Reflective Heat Transfer, Flock Transfer, Iron On Heat Transfer, Numerical Heat Transfer, Heat Transfer Equipment, Heat Transfer Machine, etc., we have established ourselves as one of Taiwan's leading brands. Our sincerity and hard work has helped us to match our quality with international standards. We produce best quality Heat Transfer Products to meet the needs of our valued customers.

Heat Transfer is a new printing technology. The printing process is divided into two major processing parts: Transfer film printing and transfer printing process. Transfer film printing pre-printed the patterns on to the film surface, with rich printed pattern layers, colorful, ever-changing color difference is small, good reproducibility, and can achieve the effect of those requirements of the patterns designers, and is suitable for mass production. Transfer printing process is through one-time processing of a heat transfer machine (heat and pressure), will transfer fine pattern of transfer membrane on to the surface of product, after forming the ink layer and the surface of the product melting into one, distinctly pretty, greatly improving product quality. Moreover, they are made of extremely high quality material, which have enhanced resistance to high temperatures. We use excellent quality imported transfer paper and ink, print out very thin layer of patterns, which is breathable, non-sticky, does not crack, and does not wash off. Therefore, they remain intact and stuck to the surface even during the harshest of weather or artificial conditions. Our Heat Transfer range is valued for their high clarity printing, water-resistance, tear-resistance, strong adhesiveness, heat-resistance and high durability. Pattern printed on the merchandise will not produce colloid, if transfer to the clothes, the ink is directly sublimated into the fabric, the fabric dyed solid degree is very well and the color is sharp, so can apply to more colorful patterns. It avoids damage problems to leather, cloth, cotton and other organic material. It caters to the diverse needs of the market, and is better able to provide users with more comprehensive production services.

More >

Other Products with This Manufacturers