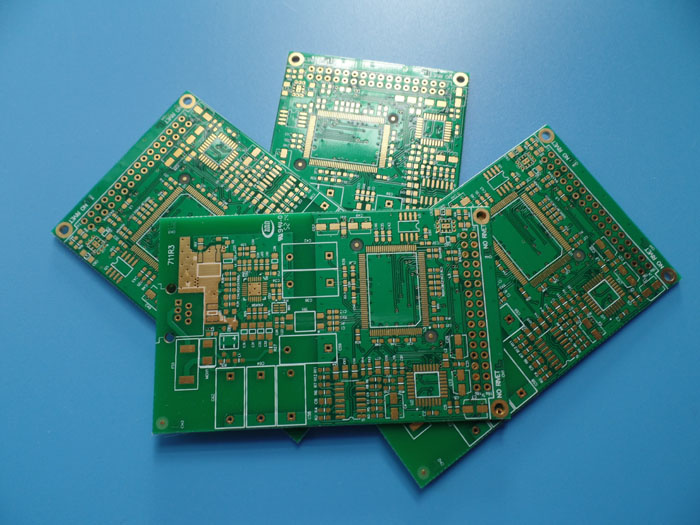

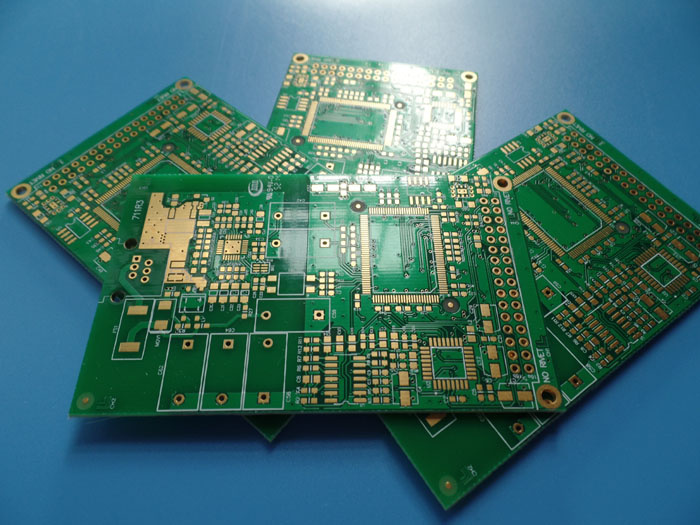

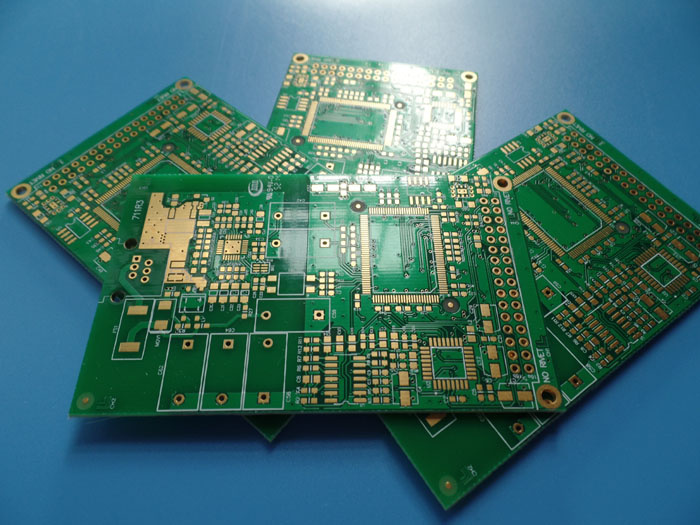

PCB 4 Layer RO4003c and RO4450b Combined with Blind Via

| Price: |

US $ 0.86/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

T/T,Western Union,Paypal |

| Prod Model: |

BIC-151-V1.51 |

| Final Foil External: |

1 Oz |

| Final Foil Internal: |

1 Oz |

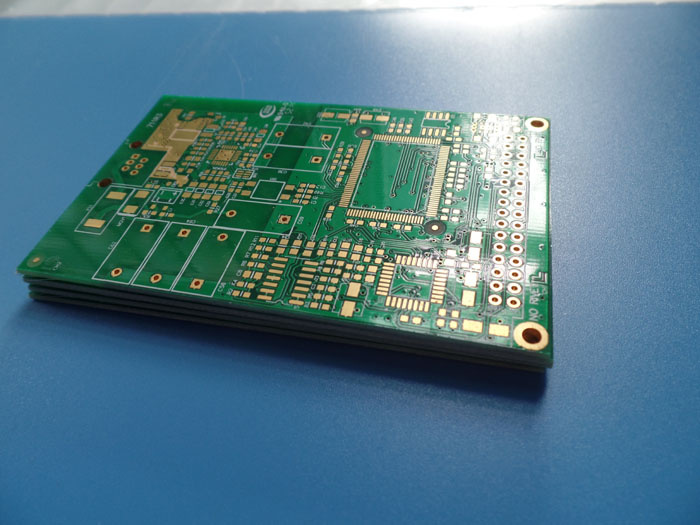

| Final Height Of PCB: |

1.6mm |

| Solder Mask Color: |

Green |

| Surface Finish: |

Immersion Gold |

| Legend Color: |

White |

| Minimum Trace And Space: |

5.9 Mil/6.1 Mil |

| Minimum / Maximum Holes: |

0.3/3.5mm |

| Test: |

100% Electrical Test Prior Shipment |

| Via: |

Plated Through Hole(Pth), Via Tented. Blind Via F |

| Type: |

Rigid Circuit Board |

| Flame Retardant Properties: |

V0 |

| Dielectric: |

RO4003c 0.305mm (12mil) and Fr-4 1.0mm Combined |

| Material: |

Hydrocarbon/Woven Glass and Fiberglass Epoxy |

| Insulation Materials: |

Glass Reinforced Hydrocarbon and Epoxy Resin |

Product Description

Hybrid Multilayer PCB RO4003C And RO4450B Combined With FR-4 Applied In

Communication Networks

Commodity IntroductionThis is a type of RO4003C and RO4450B combined with FR-4 PCB for the application of

Communication Networks. It's a 4 layer board at 1.6mm thick. The base laminate is from

ROGERS CORP and ITEQ, Solder mask and silkscreen from Taiyo. It's fabricated per

IPC 6012 Class 2 using supplied Gerber data. Each 10 boards or panels are packed

separately.  Parameters & Data Sheet

Parameters & Data Sheet| PCB SIZE | 73.5 x 55.97mm=1PCS |

| BOARD TYPE | |

| Number of Layers | Multilayer PCB, 4 layer PCB |

| Surface Mount Components | YES |

| Through Hole Components | NO |

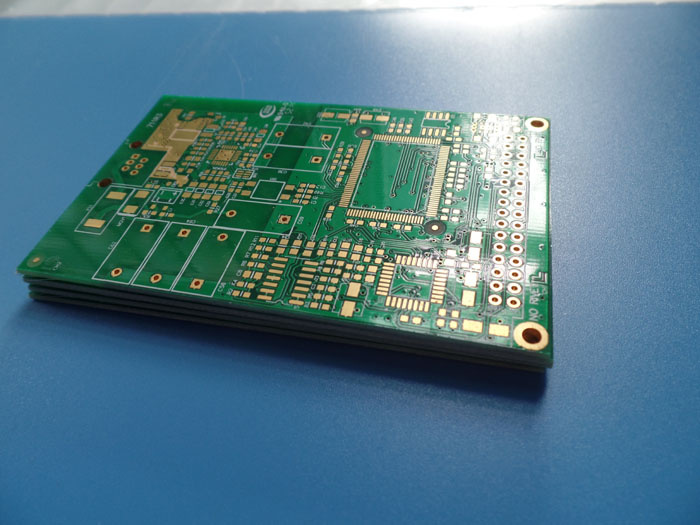

| LAYER STACKUP | copper ------- 17um(0.5oz)+plate TOP layer |

| RO4003C 0.305mm (12mil) |

| copper ------- 35um(1oz) MidLayer 1 |

| RO4450B 0.101mm |

| copper ------- 35um(1oz) MidLayer 2 |

| FR-4 1.0mm |

| copper ------- 17um(0.5oz)+plate BOT Layer |

| TECHNOLOGY | |

| Minimum Trace and Space: | 5.9mil/6.1mil |

| Minimum / Maximum Holes: | 0.3/3.5mm |

| Number of Different Holes: | 6 |

| Number of Drill Holes: | 320 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | RO4003C 0.305mm (12mil) and FR-4 1.0mm combined |

| Final foil external: | 1oz |

| Final foil internal: | 1oz |

| Final height of PCB: | 1.6mm ±0.16 |

| PLATING AND COATING | |

| Surface Finish | Immersion Gold (15.4%) 2 micoinch over

100 microinch nickel |

| Solder Mask Apply To: | TOP and Bottom, 12micron Minimum |

| Solder Mask Color: | Green, PSR-2000 GT600D, Taiyo Supplied. |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing. Fiducial marks |

| MARKING | |

| Side of Component Legend | TOP. |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo Supplied. |

| Manufacturer Name or Logo: | Marked on the board in a conductor and

leged FREE AREA |

| VIA | Plated through hole(PTH), via tented.

Blind via from top layer to Inner layer

1. Inner layer 2 to Bottom layer. |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" |

| Board plating: | 0.0029" |

| Drill tolerance: | 0.002" |

| TEST | 100% Electrical Test prior shipment |

| APPLICATION: | Communication networks, TP Link 3G Router

GSM GPRS

Voltage Converters

Cellular Repeater

Wifi Directional Antenna |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

The advantages of material RO4300 series and FR4 from Bicheng Company

The advantages of material RO4300 series and FR4 from Bicheng Company

Hybrid PCB: Hybrid of RO4350B and FR-4 material can reduce signal loss in high frequency

application. and meet the development needs of communication technology.

RO4000 Series:

A. Excellent high frequency performance due to low dielectric tolerance and loss.

B. Stable electrical coefficient of dielectric constant.

C. Excellent dimensional stability.

Frequently Asked Questions

1. Do you sell blind via PCB?

Yes. Blind via is the hole starts from top layer or bottom layer and ends at one of inner layers.

Blind viausually are plugged by epoxy resin and it's not visible by our eyes.

2. How do you control the quality?

We believe engineering design prevents problems from occurring in preproduction. Our PCB and

Manufacturing process are certified by authorized organizations.

100% tests are inclusive of electrical test and AOI inspection, high voltage test, impedance control

test,micro-section, solder-ability test, thermal stress test, reliability test, insulation resistance test

and ionic contamination test etc. Quality PolicyBicheng has developed series of management procedures and approaches to assure that PCBs are

Quality PolicyBicheng has developed series of management procedures and approaches to assure that PCBs are

in compliance with the customers' requirements, inclusive of selection of the vendors, work in progress

(WIP) inspection, outgoing delivery inspection and customer service etc. Evaluation and Audit of Suppliers Suppliers have to be evaluated by Bicheng. In addition, Bicheng will appraise and rank suppliers every

year to guarantee the materials supplied are meeting Bicheng's requirements. Furthermore, Bicheng

continuously develop suppliers and supervise them to improve their quality and environment

management basing on the systems of ISO9001 & ISO14001. Contract Evaluation Bicheng shall review and verify customer's requirements to make sure that we have the capability to satisfy customers' requirements including specifications, delivery and other demands prior to accepting an order. Making, audit and control of manufacturing data.When customers' design data and specifications are provided to our market department, Bicheng has to

verify all the requirements. Then, convert the design data into manufacturing data by CAM. Finally, a manufacturing instruction (MI) is generated according to the real manufacturing process and technologies

for manufacturing department as the basis for actual fabrication. MI must be reviewed by independent

engineers and QA engineers before issue. Incoming Material Quality ControlAll materials have to be inspected before warehousing. We established a series of strict inspection procedure and instruction to control the incoming materials. Furthermore, various precise inspecting instruments and apparatus guarantee the capability to judge the material good or not. We issue material with first in first out principle, and give out "alarm" for the material that will reach the shelf life to ensure the materials are used up before expiry.

Founded in 2003, Bicheng Enterprise Limited is a professional PCB export enterprise. We have established a good relationship of cooperation with well-known enterprises in the same industry.

The factories have been ISO 9001-2008, ISO 14001-2004 and ISO/TS16949-2009 quality management system certified. Over the past 14 years, we have provided professional circuit board manufacturing solutions for more than 5000 companies worldwide.

Different plant scale to suit for your requirements

16000 square meter factory building

30000 square meter month capability

8000 types of PCB per month

ISO9001, ISO14001, TS16949, UL Certified

We have our own advantages to help you saving cost and time spent on PCB, booster your new products go to market quickly.

A) Various kinds of PCB products

Double sided PCB

Multilayer PCB up to 32 layers

FR-4 PCB (Tg130, Tg170)

High frequency PCB (RO4350B, RO4003C)

Aluminum PCB (1W/MK, 2W/MK, 3W/MK)

Flexible PCB

HDI PCB Board

B) Multiple PCB technology to meet the market demands

Blind via PCB, Via in pad PCB, Fine pitch BGA PCB

Impedance controlled PCB

Heavy copper PCB

Hybrid material PCB

C) Many discount policies for new customers

SMT stencil foil, free of charge

Prototype shipping cost, free of charge

Prototype test, free of charge

PCB panelization, free of charge

D) High quality PCB services

Engineering design prevents problems from occurring in pre-production.

Meet your PCB needs from prototype to mass volume production.

Eligible products rate of first production: >95%

Delivery on time: >98%, door to door shipment service

Customer complaint rate: <1%

Choose BichengPCB means you choose hassle free.

More >

Other Products with This Manufacturers