Printed Circuit Board Assembly 2 Layer Electronics 3 Oz PCB

| Price: |

US $ 0.45/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

T/T,Western Union,Paypal |

| Prod Model: |

BIC-275-V2.75 |

| Board Thickness: |

1.0mm +/-0.1 |

| Tg Value Of Board Material: |

180ºC |

| Surface Finish: |

Immersion Gold |

| Surface Cu Thickness: |

105 Um (3oz) |

| Solder Mask Colour: |

Blue |

| Color Of Silkscreen: |

White |

| Total Quantity Of Components: |

87 |

| RoHS Required: |

Yes |

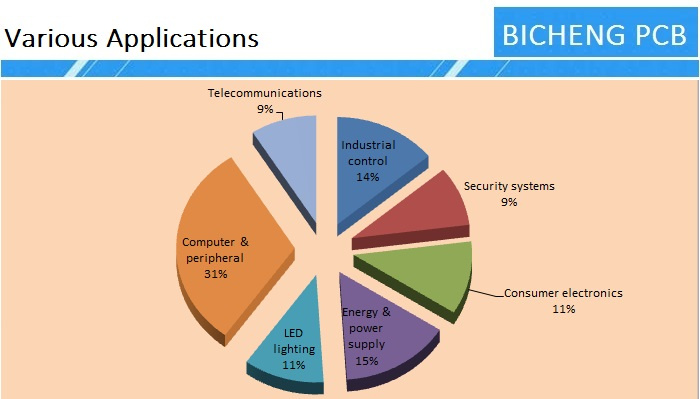

| Applications: |

USB Charger |

| Quantity of SMT: |

76 |

| Layers: |

Double-Layer |

| Certification: |

ISO |

| Customized: |

Customized |

| Metal Coating: |

Immersion Gold |

| Mode Of Production: |

SMD,SMT and Pht Assembly |

Product Description

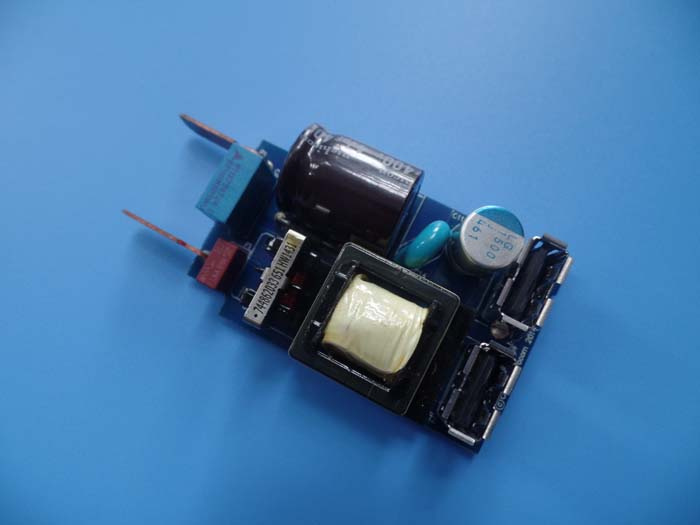

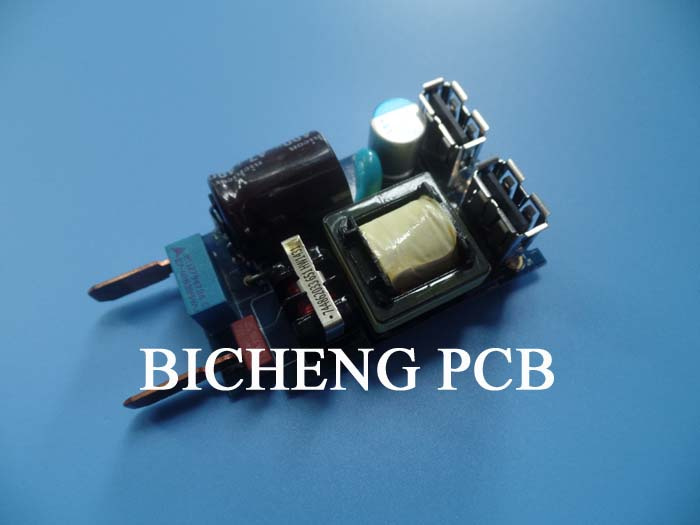

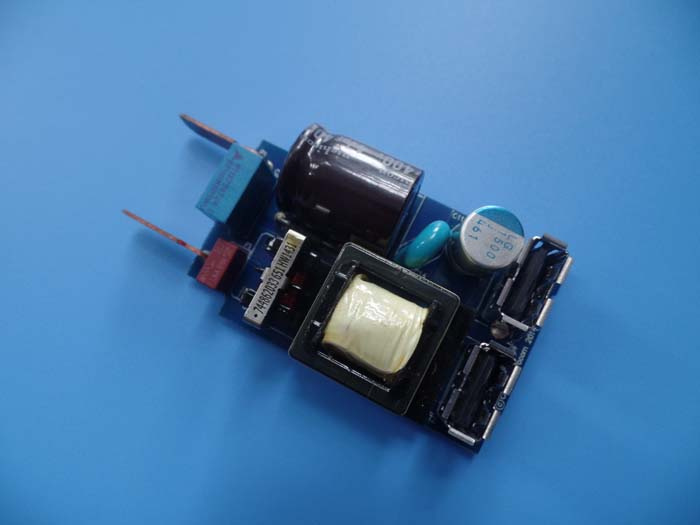

1.0mm thickness 2 Layer PCB Assembly with Immersion Gold PCB in USB Charger Commodity Introduction

Commodity Introduction

This is a type of PCB assembly job for the application of USB Charger. It's composed of SMD

assembly and through hole assembly. It's fabricated per IPC-A-610 using supplied Gerber data

and bill of material (BOM). The support board is 2 layer Tg 180 FR-4 board with 3oz copper and

Immersion gold. SMD components are on both sides.

Parameters & Data Sheet

Parameters & Data Sheet| Specifications |

| Board dimension | 76 x 38mm |

| Board Type | Double Sided PCB |

| Board Thickness | 1.0mm +/-0.1 |

| Board Material | FR-4 |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 180ºC |

| |

| Surface Finish | Immersion gold |

| RoHS Required | Yes |

| Surface Cu thickness | 105 um (3 oz) |

| |

| Color of Silkscreen | White |

| Number of Silkscreen | 2 |

| Solder Mask Colour | Blue |

| Number of Solder Masks | 2 |

| Thickness of Solder Mask | 13um |

| |

| Through hole assembly | YES |

| Sides of through hole assembly | 1 |

| SMD assembly | YES |

| Sides of SMD assembly | 2 |

| |

| Total quantity of components | 87 |

| Quantity of SMT | 76 |

| Quantity of Through holes | 11 |

| Applications | USB Charger |

Learn PCB and Buy PCB

Learn PCB and Buy PCB

The components of multilayer PCB: Prepreg

A multilayer board consists of copper foils, thin rigid laminates and prepreg sheets.

Prepreg plays a role of bonding material used for bonding the individual thin laminates of the

multilayer boards.Mit consists of glass cloth impregnated with epoxy resin. Unlikerigid laminates,

the epoxy resin is only semi-cured. Epoxy resin is referred to as B-stage when semi-cured.

The prepreg sheets are not sticky. During lamination of the board, the epoxy resin is first changed

to a liquid state and later in the press cycle to the fully cured state. During the presscycle, the cured

epoxy resin in the thin, rigid laminates softens, but it does notbecome liquid.

Thicknesses of Prepreg sheets| Glass Fabric Style | Pressed Thickness | Resin Content |

| | mm | mil | % |

| 7628H(7630) | 0.213 | 8.4 | 50 |

| 7628(43%) | 0.195 | 7.6 | 43 |

| 7628(41%) | 0.185 | 7.3 | 41 |

| 2116HR | 0.135 | 5.3 | 57 |

| 2116 | 0.12 | 4.7 | 52 |

| 2113 | 0.1 | 4 | 56 |

| 1080 | 0.076 | 3 | 64 |

| 1060 | 0.05 | 2 | 71 |

The pressed thickness varies from one manufacturer to another. As long as the PCB designer does

not know the brand(s) of the glass fabrics used by the multilayer board manufacturer, it is more

or less impossible to specify a detailed build-up. Therefore, this should be left to the manufacturer.

When a board is required impedance control, the thickness of the dielectric material between the

individual layers become important and thickness and tolerance are usually specified by designer.

The minimum thickness of the dielectric material (thin laminate or prepreg sheets) is 75 µm (3 mils)

and, in some cases, 100 µm (4 mils).

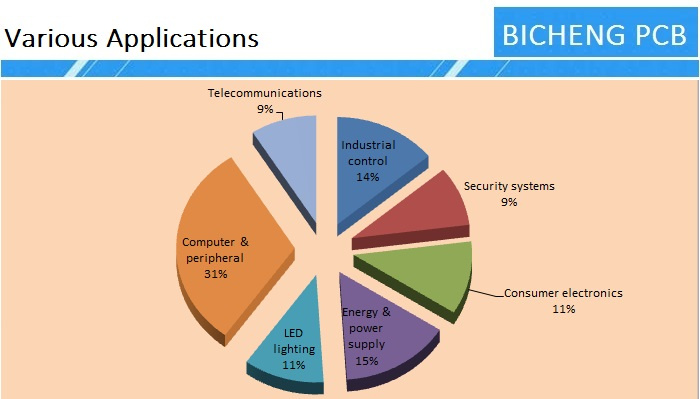

Founded in 2003, Bicheng Enterprise Limited is a professional PCB export enterprise. We have established a good relationship of cooperation with well-known enterprises in the same industry.

The factories have been ISO 9001-2008, ISO 14001-2004 and ISO/TS16949-2009 quality management system certified. Over the past 14 years, we have provided professional circuit board manufacturing solutions for more than 5000 companies worldwide.

Different plant scale to suit for your requirements

16000 square meter factory building

30000 square meter month capability

8000 types of PCB per month

ISO9001, ISO14001, TS16949, UL Certified

We have our own advantages to help you saving cost and time spent on PCB, booster your new products go to market quickly.

A) Various kinds of PCB products

Double sided PCB

Multilayer PCB up to 32 layers

FR-4 PCB (Tg130, Tg170)

High frequency PCB (RO4350B, RO4003C)

Aluminum PCB (1W/MK, 2W/MK, 3W/MK)

Flexible PCB

HDI PCB Board

B) Multiple PCB technology to meet the market demands

Blind via PCB, Via in pad PCB, Fine pitch BGA PCB

Impedance controlled PCB

Heavy copper PCB

Hybrid material PCB

C) Many discount policies for new customers

SMT stencil foil, free of charge

Prototype shipping cost, free of charge

Prototype test, free of charge

PCB panelization, free of charge

D) High quality PCB services

Engineering design prevents problems from occurring in pre-production.

Meet your PCB needs from prototype to mass volume production.

Eligible products rate of first production: >95%

Delivery on time: >98%, door to door shipment service

Customer complaint rate: <1%

Choose BichengPCB means you choose hassle free.

More >

Other Products with This Manufacturers