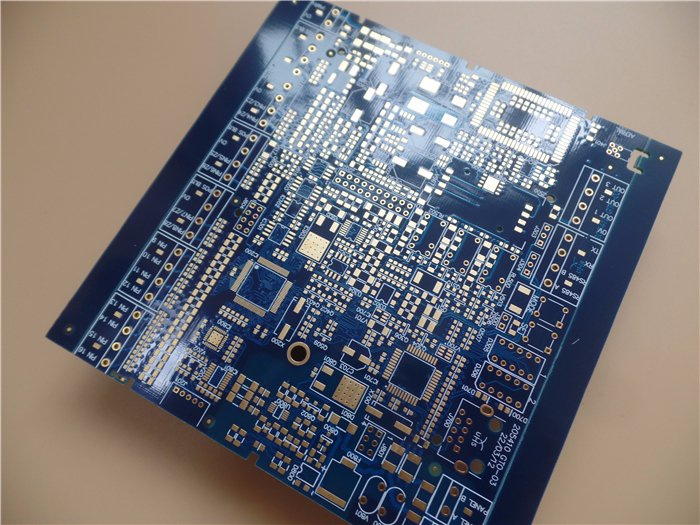

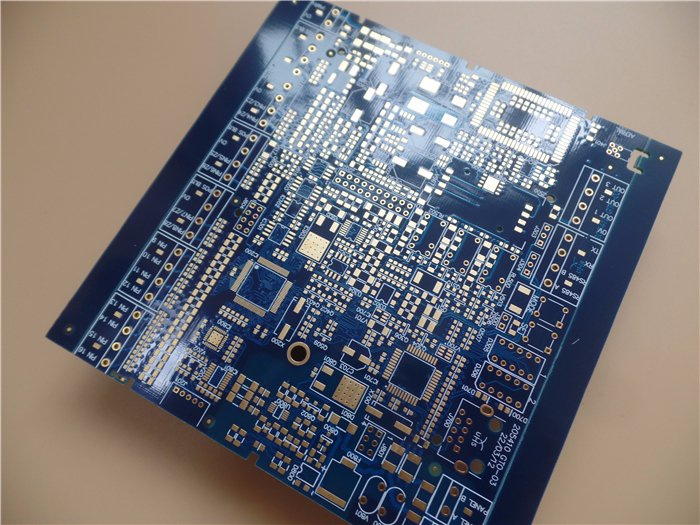

RO4350b 4 Mil (0.1mm) 14 Layer PCB Circuit Board BGA

| Price: |

US $ 1.04/Piece |

| Min Order: |

1/Piece |

| Pay Type: |

T/T,Western Union,Paypal |

| Prod Model: |

BIC-662-V6.62 |

| Board Thick: |

1.6mm |

| Surface Finish: |

Immersion Gold |

| Out Layer Copper: |

35 Um (1 Oz) |

| Soldermask Color: |

Green |

| Silkscreen Color: |

White |

| Minimum Trace And Space: |

4 Mil/4 Mil |

| Minimum / Maximum Holes: |

0.35/3.5mm |

| Final Foil Internal: |

1 Oz |

| Via: |

Plated Through Hole(Pth) |

| Test: |

100% Electrical Test |

| Type: |

Rigid Circuit Board |

| Dielectric: |

FR-4 |

| Material: |

Fiberglass Epoxy |

| Flame Retardant Properties: |

V0 |

Product Description

Company Profile

You're benefit from following 5 types of 2 layer PCB's from Bicheng Enterprise Limited.

(1) FR-4 material (The most common used today)

Normal TG, High TG 170, High CTI 600V

Material (CCL) Brand: ITEQ, SHENGYI, KB

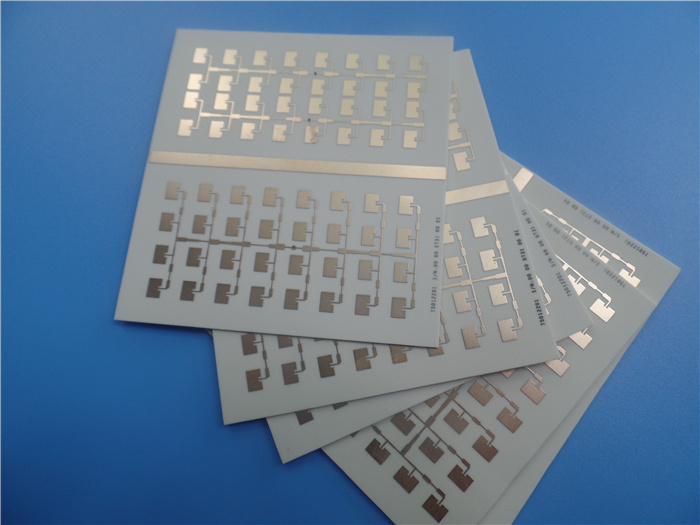

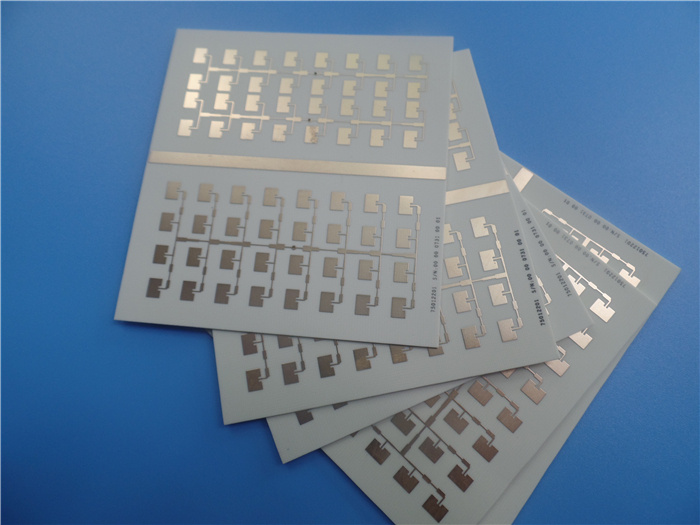

(2) High frequency material

RO4350B, RO4003C

PTFE (F4B series from China Brand)

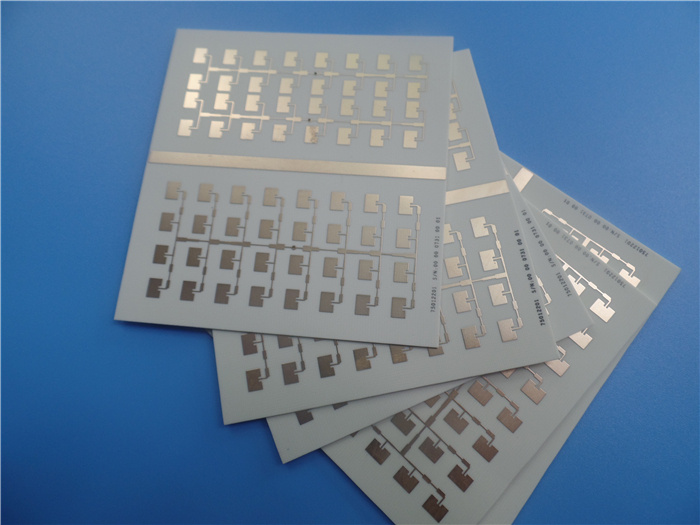

(3) Insulated Metal Substrate (IMS) PCB, typical stack-up as follows

L1---Copper conductor

PP---dielectric material

L2---copper conductor

PP---dielectric material

AL---aluminum base

(4) Metal core PCB (MCPCB), typical stack-up as follows

L1---copper conductor

PP---dielectric material

AL---aluminum core

PP---dielectric material

L2---copper conductor

(5)Polyimide material (Flexible PCB) Printed Circuit Board

Printed Circuit Board

Aluminum PCB

High Frequency PCB

Flex PCB

Technology InformationITEQ Laminate/ Prepreg : IT-180ATC / IT-180ABS

IPC-4101C Spec / 99 / 101 / 126

LAMINATE( IT-180ATC)| Property | Thickness<0.50 mm | Thickness>=0.50 mm | Units | Test

Method |

| [0.0197 in] | [0.0197 in] |

Typical

Value | Spec | Typical

Value | Spec | Metric | IPC-

TM-650 |

| (English) | (or as

noted) |

Peel Strength,

minimum | | | | | N/mm | 2.4.8 |

A. Low profile

copper foil and

very low profile

copper foil - all

copper weights

> 17mm [0.669

mil] | | | | | (lb/inch) | 2.4.8.2 |

B.Standard

profile

copper foil | 0.88 (5.0) | 0.70 (4.00) | 0.88 (5.0) | 0.70 (4.00) | | 2.4.8.3 |

1. After Thermal

Stress | | | | | | |

2. At 125°C

[257 F] | | | | | | |

3. After Process

Solutions | 1.23 (7.0) | 0.80 (4.57) | 1.40 (8.0) | 1.05 (6.00) | | |

| | 1.05 (6.0) | 0.70 (4.00) | 1.23 (7.0) | 0.70 (4.00) | | |

| | 1.05 (6.0) | 0.55 (3.14) | 1.23 (7.0) | 0.80 (4.57) | | |

Volume

Resistivity,

minimum | | | | | MW-cm | 2.5.17.1 |

| A. C-96/35/90 | 3.0x1010 | 106 | -- | -- |

B. After moisture

resistance | -- | -- | 3.0x1010 | 104 |

C. At elevated

temperature E-

24/125 | 5.0x1010 | 103 | 1.0x1010 | 103 |

Surface

Resistivity,

minimum | | | | | MW | 2.5.17.1 |

| A. C-96/35/90 | 3.0x1010 | 104 | -- | -- |

B. After moisture

resistance | -- | -- | 3.0x1010 | 104 |

C. At elevated

temperature E-

24/125 | 4.0x1010 | 103 | 4.0x1010 | 103 |

Moisture

Absorption,

maximum | -- | -- | 0.12 | 0.8 | % | 2.6.2.1 |

Dielectric

Breakdown,

minimum | -- | -- | 60 | 40 | kV | 2.5.6 |

Permittivity (Dk,

50% resin

content) | | 5.4 | | 5.4 | -- | |

(Laminate &

Laminated

Prepreg) | | | |

| A. 1MHz | 4.4 | 4.4 | 2.5.5.9 |

| B. 1GHz | 4.4 | 4.4 | |

| C. 2GHz | 4.2 | 4.3 | 2.5.5.13 |

| D. 5GHz | 4.1 | 4.1 | |

| E. 10GHz | 4 | 4.1 | |

Loss Tangent

(Df, 50% resin

content) | | 0.035 | | 0.035 | -- | |

(Laminate &

Laminated

Prepreg) | | | |

| A. 1MHz | 0.015 | 0.014 | 2.5.5.9 |

| B. 1GHz | 0.015 | 0.015 | |

| C. 2GHz | 0.015 | 0.015 | 2.5.5.13 |

| D. 5GHz | 0.016 | 0.016 | |

| E. 10GHz | 0.017 | 0.016 | |

Flexural

Strength,

minimum | | | | | N/mm2 | 2.4.4 |

A. Length

direction | -- | -- | 500-530 | 415 | (lb/in2) |

| | -- | -- | (72,500-76,850) | -60,190 | |

B. Cross

direction | -- | -- | 410-440 | 345 | |

| | -- | -- | (59,450-63,800) | -50,140 | |

Arc Resistance,

minimum | 125 | 60 | 125 | 60 | s | 2.5.1 |

Thermal Stress

10 s at 288°C

[550.4F],

minimum | | | | | Rating | 2.4.13.1 |

| A. Unetched | Pass | Pass

Visual | Pass | Pass

Visual |

| B. Etched | Pass | Pass

Visual | Pass | Pass

Visual |

Electric

Strength,

minimum | 45 | 30 | -- | -- | kV/mm | 2.5.6.2 |

(Laminate &

Laminated

Prepreg) |

| Flammability, | V-0 | V-0 | V-0 | V-0 | Rating | UL94 |

(Laminate &

Laminated

Prepreg) |

Glass Transition

Temperature

(DSC) | 175 | 170

minimum | 175 | 170

minimum | ˚C | 2.4.25 |

Decomposition

Temperature | -- | -- | 345 | 340

minimum | ˚C | 2.4.24.6 |

(5% wt

loss) |

X/Y Axis CTE

(40ºC to 125ºC) | -- | -- | 10--13 | -- | PPM/˚C | 2.4.24 |

| Z-Axis CTE | | | | | | 2.4.24 |

| A. Alpha 1 | -- | -- | 45 | 60

maximum | PPM/˚C |

| B. Alpha 2 | -- | -- | 210 | 300

maximum | PPM/˚C |

C. 50 to

260 Degrees

C | -- | -- | 2.7 | 3.0

maximum | % |

Thermal

Resistance | | | | | | 2.4.24.1 |

| A. T260 | -- | -- | >60 | 30

minimum | Minutes |

| B. T288 | -- | -- | >30 | 15

minimum | Minutes |

CAF

Resistance | -- | -- | Pass | AABUS | Pass/Fail | 2.6.25 |

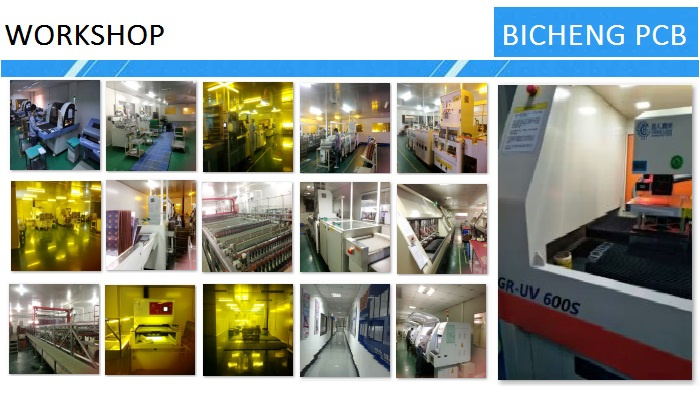

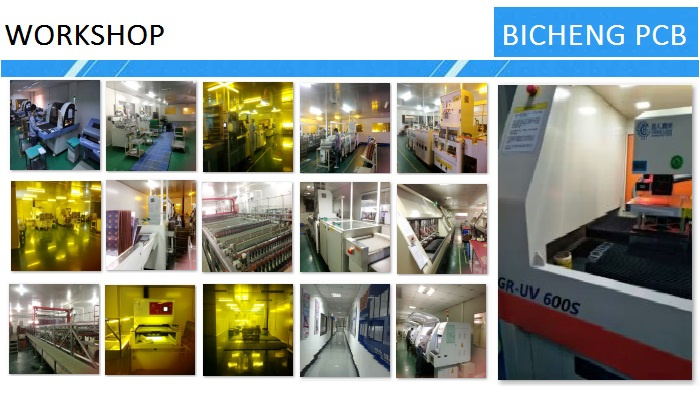

Founded in 2003, Bicheng Enterprise Limited is a professional PCB export enterprise. We have established a good relationship of cooperation with well-known enterprises in the same industry.

The factories have been ISO 9001-2008, ISO 14001-2004 and ISO/TS16949-2009 quality management system certified. Over the past 14 years, we have provided professional circuit board manufacturing solutions for more than 5000 companies worldwide.

Different plant scale to suit for your requirements

16000 square meter factory building

30000 square meter month capability

8000 types of PCB per month

ISO9001, ISO14001, TS16949, UL Certified

We have our own advantages to help you saving cost and time spent on PCB, booster your new products go to market quickly.

A) Various kinds of PCB products

Double sided PCB

Multilayer PCB up to 32 layers

FR-4 PCB (Tg130, Tg170)

High frequency PCB (RO4350B, RO4003C)

Aluminum PCB (1W/MK, 2W/MK, 3W/MK)

Flexible PCB

HDI PCB Board

B) Multiple PCB technology to meet the market demands

Blind via PCB, Via in pad PCB, Fine pitch BGA PCB

Impedance controlled PCB

Heavy copper PCB

Hybrid material PCB

C) Many discount policies for new customers

SMT stencil foil, free of charge

Prototype shipping cost, free of charge

Prototype test, free of charge

PCB panelization, free of charge

D) High quality PCB services

Engineering design prevents problems from occurring in pre-production.

Meet your PCB needs from prototype to mass volume production.

Eligible products rate of first production: >95%

Delivery on time: >98%, door to door shipment service

Customer complaint rate: <1%

Choose BichengPCB means you choose hassle free.

More >

Other Products with This Manufacturers