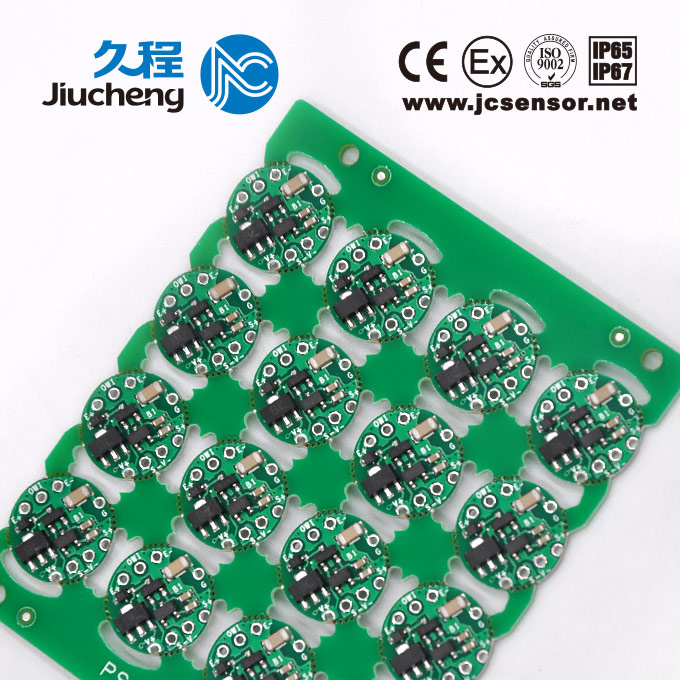

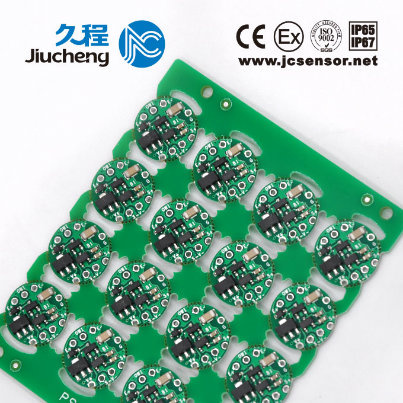

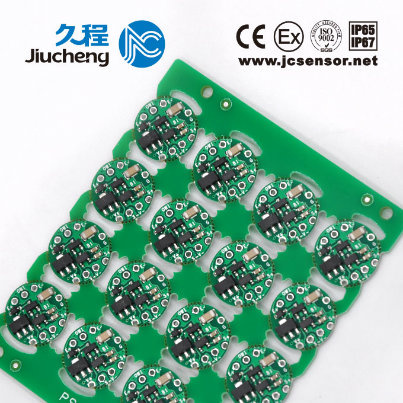

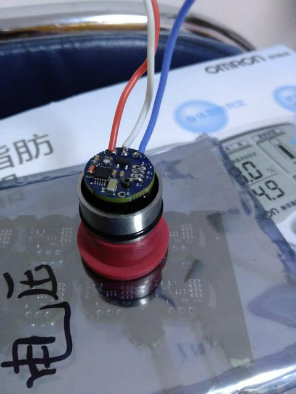

Smart01 PCB Pressure Transfer Module

| Price: |

US $ 3.9-5/Piece |

| Min Order: |

1000/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union,Money Gram |

| Prod Model: |

Smart01 |

| Type: |

Rigid Circuit Board |

| Material: |

Complex |

Product Description

Product overview SMART series pressure transfer module is a digital regulating analog output model of small volume pressure transformer, which is especially suitable for ultra small pressure and liquid level transmitter.

SMART series pressure transfer module adopts the self-developed adjusting tool, adjusting the power supply of the tool circuit, and carrying the precision ammeter and voltmeter. In the process of calibration, the closed loop automatically calibrates the voltage and current value, and the independent power supply and the multimeter are not needed, and the debugging is convenient and quick.

The electronic components of the SMART series pressure transfer module are all imported devices, to ensure stable and reliable operation, and enhance the EMC anti-jamming design. It is suitable for all kinds of electromagnetic environment harsh industrial environment. It has the characteristics of strong anti-interference ability, low noise and fast response speed.

Performance indexThe following table parameters are measured at ambient temperature 24ºC, power supply voltage 24Vdc, sensor impedance 1kohm and sensor sensitivity under 2mV/V

Performance indexThe following table parameters are measured at ambient temperature 24ºC, power supply voltage 24Vdc, sensor impedance 1kohm and sensor sensitivity under 2mV/V | Impedance of matching sensor | Sensitivity of matching sensor | Zero of matching sensor | Output precision | Output noise | Response | Nonlinearity | Temperature coefficient | Long-term stability |

| ohm | mV/V | ±mV | ±FS*% | uA | ms | ±FS*% | ±ppm/ºC | ±FS%year |

| 350 ~ 20000 | 0.5 ~ 200 | 80 | 0.05 | 1 | 0.5 | 0.005 | 25 | 0.05 |

| |

| Common mode rejection ratio of input signal | Power supply voltage rejection ratio | Overcurrent protection | Overvoltage protection | working voltage | Polarity protection | Load resistance | Relative humidity | Working temperature |

| dB | dB | ≤ mA | ≤ V | Vdc | Vdc | ohm | % | ºC |

| 120 | 150 | 24 | 50 | 10 ~ 45 | 45 | 750 | 20 ~ 80 | -40 ~ 125 |

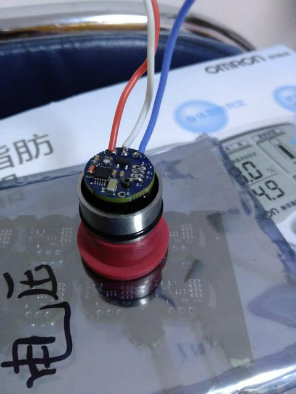

Note1, matching the impedance of the sensor: the converter plate can accept the resistance value at both ends of the sensor power supply.2, matching sensor sensitivity: the feed board can accept the ratio of the output signal of the sensor to the power supply voltage of the sensor.3, the matching sensor zero point: the converter plate can accept the signal value of the sensor output in the unpressurized initial state.4. Output precision: the precision of the variable feed plate for full range.5, output noise: the lower the impedance and sensitivity of the sensor, the higher the output noise of the converter plate.6, response time: when the sensor changes + FS 0.05%, the output board (4... 20mA) the time required to change the corresponding + FS 0.05%.7. Nonlinear: the percentage of the full range.8, temperature drift coefficient: the change plate temperature is 1 degrees centigrade, the output change 5e-5mA9. Long-term stable period: the percentage of the full range change every other year.10. The higher the CMRR of the input signal, the higher the ability to represent the anti-interference ability.11. The higher the power supply voltage rejection ratio: the higher the ability to represent the anti-interference ability.12, reverse voltage resistance: the maximum voltage that does not damage the power supply is the maximum withstand voltage of the antipole protection.Usage 1, in order to improve the reliability of SMART, OTP firmware is used. So it can't be more than 4 times to calibrate the data write times. Please operate carefully when the data is written. Zero - and full - degree data for more than 4 times written to fourth times.2, the whole signal chain of SMART1 is an analog channel, and the background noise is low and the response speed is fast. But it does not have the function of linear correction and temperature compensation.Installation and debugging method Installation method: (with the soldering iron to weld the board terminal, the soldering iron needs to be grounded to prevent the static damage to the pressure transfer plate).1, the E+ on the pressure transfer board corresponds to the positive end and E- corresponding to the negative end of the excitation, which is connected to the connection seat and interconnected with the peripheral.2. The power supply of the pressure sensor, the negative signal, the negative power and the positive signal are connected to the V+, S-, V- and S+ terminals of the pressure transfer board.3, the D end of the pressure transfer board is connected to the shell of the sensor. If the capacitance of the sensor is large, it must be connected.

Connection modeWith the debugging tool wiring method of our company, the PWO+ ,PWO- ends of the debugging tools are respectively connected to the positive end of the transmitter and the negative end of the excitation. OWI-, OWI+ connection board debugging line (that is, the 2 side of the triode, which has the A1 screen side of the side +).

Connection modeWith the debugging tool wiring method of our company, the PWO+ ,PWO- ends of the debugging tools are respectively connected to the positive end of the transmitter and the negative end of the excitation. OWI-, OWI+ connection board debugging line (that is, the 2 side of the triode, which has the A1 screen side of the side +).

Established in 2006, Nanjing Helm Sci-tech Co., Ltd. (Nanjing Jiucheng technology Co., Ltd) is specialized in R&D and production of pressure measuring and controlling instruments. It has introduced the internationally advanced production technology, equipment and process as well as strict product quality standards and ODM cooperation concept to China, so as to manufacture and sell JC pressure / differential pressure / liquid level sensors and transducers in mainland China.

Our products have been fallen into six categories totaling hundreds of specifications in dozens of series. Main products include: High-accuracy Pressure Sensor, General-purpose Pressure transducer, Liquid Level transducer, Anti-lightning/Anti-corrosive Liquid Level transducer, Special Pressure transducer for Air Conditioner, Refrigeration and Compressor, Special Pressure transducer for Oilfield and Mining Well, Economical Pressure Sensor and transducer, Ceramic Capacitor Pressure transducer, Vacuum Pressure transducer, Sapphire Pressure transducer, Digital Pressure transducer, Micro Differential Pressure / Air Pressure transducer, Intelligent Digital Pressure Gauge, Intelligent Digital Pressure Switch, Anti-corrosive Pressure transducer, Anti-explosive Pressure transducer, Hygienically Flat-membrane Pressure transducer, High-temperature Pressure transducer, High-frequency Pressure transducer, Micro Pressure transducer, Integrated Temperature transducer, and Capacitance Pressure transducer.

More >

Other Products with This Manufacturers